| Model: | WR0001 |

|---|---|

| Brand: | Yashin |

| Origin: | Made In China |

| Category: | Transportation / Logistics / Conveying Systems |

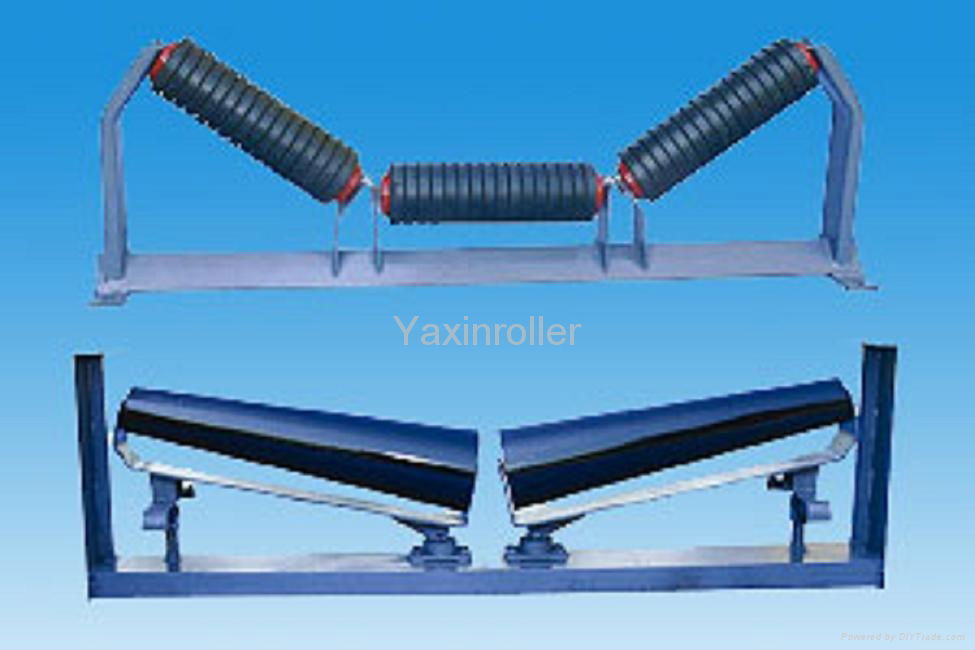

| Label: | weighting roller , weight roller , conveyor roller |

| Price: |

-

|

| Min. Order: | 10 pc |

Product Description

The steel pipe of weighting idlers is special high-frequency welded pipe for producing Weight Idlers. It is deal well in thorns, roundness control is in the special tolerance range. The axis is processing a=by cold drawn steel, which is produced as per the international standard & tolerance.

The bearing base is made by repeatedly stamping process of imported cold rolling steel plate.

Roller bearing base and Roller bearing shells are welded together by automatic welding robot and form a high strength of the overall structure.

The roller bearing is purchase from renown factory from China or overseas country. The bearing balls are double sealed, so that idler has the ideal balance between static and dynamic balance, the rotation resistance is better than the national standard.Bearing roller integrated labyrinth seals of a special design of external and internal characteristics, forming a unique sealing, High-resistant,high-speed filling and ultra-low temperature oxidation of lithium acetate-based, effective prevention of impurities, water, air on Roller internal erosion.

Member Information

| Hengshui Yaxin Conveying Machinery Co.,Ltd. | |

|---|---|

| Country/Region: | He Bei - China |

| Business Nature: | Manufacturer |

| Phone: | 15822696954 |

| Contact: | Alma Pu (Manager) |

| Last Online: | 26 Mar, 2012 |