| Model: | FG-004 |

|---|---|

| Brand: | CREDIT |

| Origin: | Made In China |

| Category: | Construction & Decoration / Building Glass & Mirror |

| Label: | float glass , tinted glass , building glass |

| Price: |

-

|

| Min. Order: | - |

Product Description

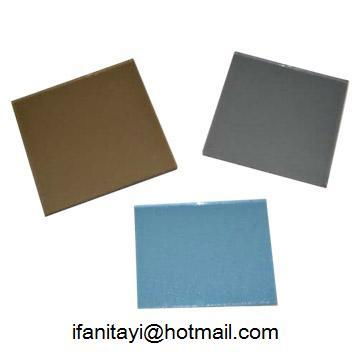

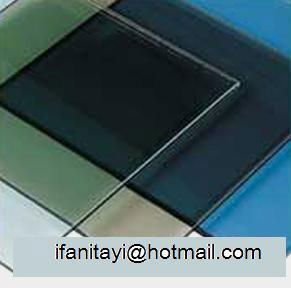

Body tinted or heat absorbing glass is produced on the float process by adding small quantities of metal oxides to the normal clear glass raw materials in the batching plant.

Addition of colorant does not affect the basic properties of the glass although visible light reflectance will be slightly lower than clear glass. The color density will increase with thickness while the visible light transmittance will decrease corresponding to increase in thickness.

Tinted glass reduces solar transmittance by absorbing a large proportion of the solar energy, the majority of which is subsequently dissipated to the outside by re-radiation and convection.

Glass range of vibrant colours blend in perfectly with any building faade and provide varying degrees of solar control and energy saving.

Our comprehensive range of soft natural colours compliments and harmonizes with modern building materials to provide an exciting and different look to new and existing buildings.

tinted float glass is available in standard thicknesses of 4, 5 and 6mm. On some of our colours thicknesses of 8, 10 and 12mm can also be provided. Non - standard thicknesses can also be produced to order.

The range of vibrant colours, excellent performance characteristics and post treatment possibilities make tinted float glass the ideal choice for architects for application in new construction or renovation projects

| Payment Terms: | TT/LC/DP/DA |

|---|---|

Member Information

| Qingdao Jinghaiyuan Glass co.,ltd | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18561653776 |

| Contact: | Alice.lynn (Manager) |

| Last Online: | 20 Jan, 2014 |

Related Products of this Company

-

Mirror-processing mirror

-

FLOAT GLASS- ultra clear float glass

-

Processed glass-Figured acid etched

-

Patterned Glass-wired patterned glass

-

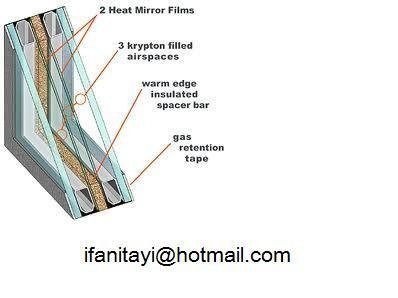

FLOAT GLASS-low-e glass

-

Processed glass-double glazing glass

-

Patterned Glass-ultra clear patterned

-

Mirror-silver mirror

-

Mirror-furniture mirror

-

FLOAT GLASS-reflective glass