| Model: | LeakTESTER |

|---|---|

| Brand: | SDT |

| Origin: | Made In Belgium |

| Category: | Electronics & Electricity / Electronic Instrument / Electronic Measurment Apparatus |

| Label: | Mass flow , tightness testing , LeakTESTER |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Nothing escapes it. Your escort to optimal productivity: Large range of measurement, fast measurement and for all kinds of applications.

The SDT LeakTESTER operates on the principle of Mass Flow for manual or automatic testing of any component which must meet rigid tightness criteria, such as taps, catheters, pouches, flasks, packaging, bottles, syringes, cartridges, cooling circuits, shock absorbers, etc.

Tightness is measured by recording the flow of gas (air, nitrogen, etc.), not the difference in pressure, between the reference volume and the piece being tested. A measurement is made of the flow rate in a flow sensor (mass flow sensor).

Integration of the SDT LeakTESTER into the production chain is accompanied by the installation of pneumatic equipment whose control valves are opened and closed by the SDT LeakTESTER itself.

The SDT LeakTESTER receives data from the mass flow sensor, allowing it to validate or reject tested products, and controls the validation equipment in the testing chain (lights, relays, production data, etc.).

The SDT LeakTESTER is a centralised electronic measurement unit which provides simultaneous automatic testing for leaks of 1 to 8 pieces generally as they emerge from the manufacturing process.

Measurement range depends on sensor: 25/+25 SCCM and -100/+1000 SCCM. Pressure test: up to 10 bar relative.

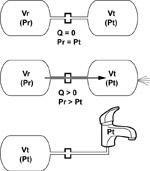

The principle of measuring mass flow.

The SDT LeakTESTER works on the principle of measuring the mass flow between a buffer reservoir (reference volume) and the volume to be tested. It is the principle of communicating vessels applied to gases (Boyle's law).

The two volumes, which are not necessarily equal, are filled with air. P1 is the pressure of the reference volume and P2 the pressure in the item being tested. Pressures P1 and P2 are equal.

If the volume to be tested has no leaks, the pressures remain identical; the flow of air in the mass flow meter is zero. If the piece is not leak-tight, its pressure loss will be compensated for by pressure P1 of the reference volume. This will result in a gas flow which is detected immediately.

The measuring unit used by the mass flow sensor in the SDT LeakTESTER is the SCCM (Standard Cubic Centimeter per Minute).

Challenge the SDT LeakTESTER to satisfy your requirements.

Unlike the method commonly used to measure a drop in pressure (pressure decay or delta-p), the SDT LeakTESTER also meets the growing demands of all manufacturers.

We offer you the possibility to perform a detailed capability test, taking in consideration your production rate, tightness criteria, technical environment and your production diversity. Our laboratory is equipped to test your good and bad sample parts. Next we perform an accurate feasibility study.

Customized service

Once the challenge is accepted, our support services will guide you integrating the SDT LeakTESTER seamlessly on your production lines. SDT proposes tailored products: they provide the LeakTESTER module only or assembled with requested accessories (fine-tuned electro-pneumatic system and casing).

SDT focus on:Leak Detection|Leaks|air leaks|Tightness Testing|Tightness|Water Leaks|Wind Noise|Hatch Cover Testing |Ultrasound Testing|

Member Information

| Kim-Mac MAC equipments Co.,Ltd | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Trading Company |

| Phone: | 50333915 |

| Contact: | Sean.kim (Sales Manager) |

| Last Online: | 17 Sep, 2015 |