| Model: | VLA20 0544N |

|---|---|

| Brand: | SOCARE |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machine Hardware / Other Machine Hardware |

| Label: | slewing ring bearing , slewing drives , ring bearing |

| Price: |

-

|

| Min. Order: | 10 pc |

Product Description

Description:

A Slewing Bearing is a piece of hardware used to facilitate circular movement, usually of a large device such as a crane. The term "slew" means to turn without changing location, so a slewing bearing is one that will not move out of place but will instead facilitate movement while in one position. These bearings are usually quite large and are used for heavy-duty applications; they are therefore usually made from heavy-duty metals such as steel, though other materials including aluminum and titanium can be used for their construction as well.

A Slewing Bearing is a piece of hardware used to facilitate circular movement, usually of a large device such as a crane. The term "slew" means to turn without changing location, so a slewing bearing is one that will not move out of place but will instead facilitate movement while in one position. These bearings are usually quite large and are used for heavy-duty applications; they are therefore usually made from heavy-duty metals such as steel, though other materials including aluminum and titanium can be used for their construction as well.

The slewing bearing is not mounted on a shaft, but is instead bolted to a flat surface. The gears allow one part of the bearing to move while the other stays in place, thereby facilitating movement. The path of the movement can vary; sometimes the slewing bearing is used to facilitate round movement, while in other cases an oscillating movement can be performed. The type of movement depends on the configuration of the slewing bearing as well as the location of the gears. The gears allow a platform to be driven in a certain motion, and the location of the gears will depend on the design of the device.

The profile of the slewing bearing is usually quite thin, allowing the distance between platforms to be very narrow. Ball bearings are present within the bearing race to ensure movement is smooth and constant; these ball bearings may need to be lubricated or greased periodically to prevent premature breakdown or abnormal shaping of the balls. Most devices that use these types of bearings are quite large and slow-moving, but constant movement and high temperatures can alter the shape and function of the bearings over time, thereby necessitating maintenance or repair.

Heavy machinery devices often use a slewing bearing between the vehicle's base and the upper part of the vehicle, which is sometimes known as a house. An excavator, for example, features a base and a house that rotate independently from each other. This is accomplished by using a slewing bearing between the two parts of the vehicle; the outer ring of the bearing will be bolted to the base of the machine, while the inner ring will be bolted to the house. A drive gear may be located on the outside or inside of the ring to allow a drive unit to turn the house as necessary.

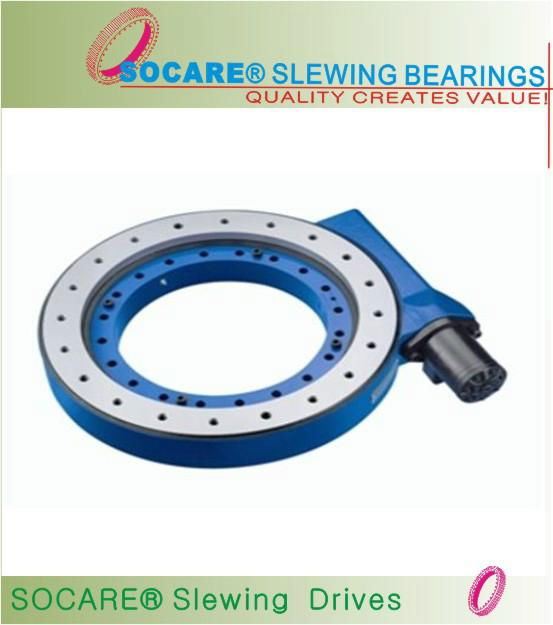

Slewing Drives:

The term "slewing drive" most often refers to a mechanism that consists of a radial gear, an axial shaft called a worm, and a connected driving component. More advanced slew drivesmight include specific worm designs, protective enclosures and other auxiliary components.Slewing drives are capable of transferring forces and torque as well as sustaining those forces over time. There are many applications for slewing drives, a few different materials to choose from, and a long history.

The most basic slewing drive has a radial gear driven by the worm. The teeth of the gear meet with the grooves in the worm and, as the worm turns, the gear also turns. Common features for different slewing drives can include an hourglass-shaped worm, which is often considered more efficient because multiple teeth on the gear can be engaged at once. Other features can include a protective enclosure meant to keep the mechanisms clean. The motor or driving component, like the spinning of a wind turbine, also might change the specific design of aslewing drive.

In general, the purpose of these machines is to change axial movement to radial movement. Depending on the number of threads on the worm and the number of teeth on the gear, the speed and power of the axial force will be converted to a specific radial force. Depending on the application, a slewing drive might be useful for amplifying the torque that rotates a mechanism.

Slew drives have many applications. For instance, wind energy systems often use a slewingdrive to convert the axial movement created by the turbine to an amplified radial movement that can be converted into energy. Solar tracking systems also might include slew drives to maintain the best location for solar panels as the sun moves across the sky. Further applications of a slewing drive can include hydraulic systems and mechanical lifts.

Materials used to create slewing drives are somewhat consistent. Most often, steel with phosphor bronze provides high strength and consistent protection from corrosion. Materials also might include varieties of bronze such as nickel-phosphor bronze added to steel, depending on the application.

These devices have a long history, perhaps starting in ancient Greece with a device called the endless screw. Slewing drives were common in the Renaissance, as well. Though modern slewdrives perform more complex tasks and are made out of more advanced materials, the ultimate goal of a slewing drive hasn’t changed much over time.

Member Information

| SOCARE INTERNATIONAL (QINGDAO)CO.,LTD | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 18653028886 |

| Contact: | Mr.BingTin (Sales Manager) |

| Last Online: | 13 Jul, 2023 |