| Model: | AM-4104 |

|---|---|

| Brand: | ALUMARK |

| Origin: | Made In China |

| Category: | Construction & Decoration / Curtain Wall |

| Label: | aluminium composite , material , ACM |

| Price: |

US $7.2

/ SQM

|

| Min. Order: | 1000 SQM |

Product Description

PVDF Aluminum Composite Material (ACM )

1.ISO9001,SGS

2.Warranty:15year

3.Delivery time:15day

4.Standard size:1220*2440*3/4mm

5.Weather resistant,Fire,waterproof

1. Quality

1.ISO9001,SGS

2.Warranty:15year

3.Delivery time:15day

4.Standard size:1220*2440*3/4mm

5.Weather resistant,Fire,waterproof

1. Quality

1)Under natural climate ,film coating will be no flake .no rubbles ,no vestige and no pulverization.

2)Under common environment.no flake.no rubbles.

3)Under common temperatures and radiation,no color deferent.

4)According to international test standard,all the tested items are satisfied with high-class.

5)Our products with PVDF coating which produced under GB/T17748-1999 is with 70% PVDF.and under common environment,we can guarantee 10~15 years;and for FR products,it is good at fireproof,and the FR grade is B1(according to the standard Q B8624).

2. Dimensions

2. Dimensions

Standard size: 1220mm x 2440mm x 3mm and 1220mm x 2440mm x 4mm

Accepted thickness: 3mm, 4mm, 5mm, 6mm

Accepted width: From 1000mm to 2000mm

Such as: 1220mm, 1250mm, 1500mm, 1575mm,2000mm

Accepted length: According to buyer’s requirement

Accepted aluminum sheet thickness :0.15~0.5mm

Such as:0.15mm,0.21mm,0.27mm,0.3mm,0.35mm,0.4mm,0.45mm,0.5mm

3.Seaworthy packing

1) 20 foot container: 2mm panel-6000M2, 3mm panel-5000M2, 4mm panel-4000M2, 5mm panel-3000M2.

2) 40 foot container:2mm panel-8000M2, 3mm panel-7000M2, 4mm panel-6000M2, 5mm panel-5000M2.

4. Range of applications

1. Can be widely used in galleries, exhibitions, saloons, stores, offices, banks, hotels, restaurants, and apartments .

2. Other kinds of buildings: as ideal decorative materials for the outer-wall and inner-wall of buildings.

3. Kitchen cabinets, billboards, signboards, tunnels and subway interiors.

4. Ceilings, eaves, balconies, partitions and interior decorations.

5. Telephone booths, vehicle bodies, and industrial usages.

6. Re-decoration of the old building

5. Features

a) Light weight, flat surface and high strength

b) Excellent heat insulation, sound insulation, fire-resistance, acid-resistance, alkali-resistance, weatherproofness and non-resonance.

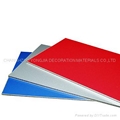

c) Various uniform colors

d) Can be easily processed and quickly installed

e) Bright, elegant and magnificent, fit for various designs

f) PVDF resin features strong chemical resistance, unique colors can be easily maintained.

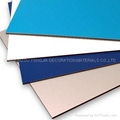

6. material

a)Top : aluminium alloy sheet coated with fluoro-carbon resin (PVDF) and polyestor resin (PE) roasting painting.

b) core:non-toxic polyethylene or fireproof material

c) back:aluminium alloy sheet coated with polyester resin painting

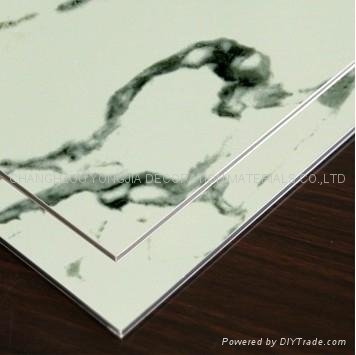

d) surface finish: PVDF / PE resin,brush finish ,mirror finish ,wooden faced,nano painting ect.

e) surface coating thickness :30 um 70% KYNAR PVDF

3.Seaworthy packing

1) 20 foot container: 2mm panel-6000M2, 3mm panel-5000M2, 4mm panel-4000M2, 5mm panel-3000M2.

2) 40 foot container:2mm panel-8000M2, 3mm panel-7000M2, 4mm panel-6000M2, 5mm panel-5000M2.

4. Range of applications

1. Can be widely used in galleries, exhibitions, saloons, stores, offices, banks, hotels, restaurants, and apartments .

2. Other kinds of buildings: as ideal decorative materials for the outer-wall and inner-wall of buildings.

3. Kitchen cabinets, billboards, signboards, tunnels and subway interiors.

4. Ceilings, eaves, balconies, partitions and interior decorations.

5. Telephone booths, vehicle bodies, and industrial usages.

6. Re-decoration of the old building

5. Features

a) Light weight, flat surface and high strength

b) Excellent heat insulation, sound insulation, fire-resistance, acid-resistance, alkali-resistance, weatherproofness and non-resonance.

c) Various uniform colors

d) Can be easily processed and quickly installed

e) Bright, elegant and magnificent, fit for various designs

f) PVDF resin features strong chemical resistance, unique colors can be easily maintained.

6. material

a)Top : aluminium alloy sheet coated with fluoro-carbon resin (PVDF) and polyestor resin (PE) roasting painting.

b) core:non-toxic polyethylene or fireproof material

c) back:aluminium alloy sheet coated with polyester resin painting

d) surface finish: PVDF / PE resin,brush finish ,mirror finish ,wooden faced,nano painting ect.

e) surface coating thickness :30 um 70% KYNAR PVDF

Member Information

| SHANGHAI (WENZHOU) JIXIANG COMPOSITE PANEL CO.,LTD | |

|---|---|

| Country/Region: | Zhe Jiang - China |

| Business Nature: | Manufacturer |

| Phone: | 18019085530 |

| Contact: | Brant Wu (Export Manager) |

| Last Online: | 01 Mar, 2015 |

Related Products of this Company

-

aluminum composite board

US $7.2

-

curtain wall aluminum composite panel

US $7

-

Fireproof PVDF aluminum composite panel

US $7.2

-

acb

US $7

-

composite panel

US $7

-

Digital Printing Signage Aluminum

US $7

-

alubond boards

US $7.2

-

panels

US $7

-

Curtain Wall Aluminium Composite Panel

US $7

-

alubond panels

US $7