| Model: | JH series |

|---|---|

| Brand: | EMM |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Machine Tool |

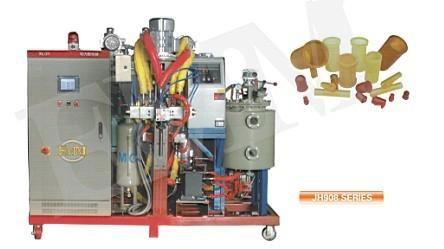

| Label: | Polyurethane machine , pressure machine , foaming machine |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

1、Feature:

JH series low pressure foaming machine is high-tech model combined with international technology and after market research for polyurethane industry application. Main parts are imported and the whole equipment has reliable performance and high safety standard.

JH608,adopts one tank for POLY.、one tank for ISO., Two metering units control outflow of metering pumps. Density is adjusted by various mixing ratio. Professional in foam industry manufacture.

2、Technical capacity

2.1 Model:JH608-2

2.2 Foam type:soft foaming、half-hard foaming

2.3 Viscosity: (22℃)

POLY:~2000mPas

ISO:~1000mPas

2.4 Injection flow (mix ratio 2:1):50-250g/s

Adjust range of mix ratio:5:1~1:1

2.5 Injection time:0.01~9.99 (accuracy reach 0.01s)

2.6 Injection Program No.:

Hand-injection:9

Auto-injection:99

2.7 Measure unit:measure accuracy ≤0.5%

|

Component material

|

POLY

|

ISO.

|

|

Quantity

|

1

|

1

|

|

Metering Pump model

|

NB3-C40F(40cc/r)

|

NB3-C40F(40cc/r)

|

|

Motor power(kw)

|

5.5

|

5.5

|

|

Motor speed(rpm)

|

500-1450

|

500-1450

|

|

|

DOP

|

DOP

|

For component’s measurement, It includes bracket with vibration pads, variable frequency motor, coupling, axial piston pumps and valves, electronic pressure switches, etc.

2.8 Pressure limit and control system Working pressure range is 0~4MPa for components, if beyond setting range, machine stop injection automatically and alarm

2.9 Flow measurement and control system

According to the pump output flow and process requirements mixture components and related parameters; group were traffic speed control motor speed by changing the pump output flow, remove the mixing head, with each injection valve so that A, B flow to each container of raw materials . Flow of each component separately and mixing parameters to detect than the parameters, correction to achieve the component flow regulation and control.

2.10 Component filter

Two components have independent mesh filter between metering pump and barrel. Filtering accuracy is 330μm.

2.11 Mixing head

Materials to the mixing chamber through the spit valve injection precision, synchronization, no plug.

- Mixing head by the motor driving mechanical mixing;

- Between the motor and the stirring shaft through the belt transmission speed can be adjusted by adjusting the motor to facilitate the completion of the push-pull;

- In the test state, the motor and the stirring shaft does not rotate;

- Stir in advance and lag time from the electrical control, optional automatic and manual mixing modes;

- Opening and closing the valve from the cylinder control;

- Mixing head, mixed with a cone of the nozzle chamber, as well as to facilitate removal;

- Adjustable needle valve regulating the pressure in each group were balanced;

- Head control box can be foam, stop foaming, cleaning, air blasting, emergency stop, etc. buttons.

2.12 Rack and mixed head cantilever system

Frame

Materials for the installation of tanks, metering system, mixing head cantilever.

Mixed head cantilever piping system and installation to support the mixing head and procedures for the button box, from the center of rotation to the end of arm length 2200mm.

- A spring balance device to mix head can move up and down;

- Horizontal rotation range of 160 °

Member Information

| Extreme Machinery Manufacture Co.,Ltd | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Trading Company |

| Phone: | 13952608133 |

| Contact: | Joan Wang (General manager) |

| Last Online: | 22 Aug, 2015 |