| Model: | YLUV-1-1000 |

|---|---|

| Brand: | YULI |

| Origin: | Made In China |

| Category: | Consumer Electronics & Lighting / Lighting / LED Lighting |

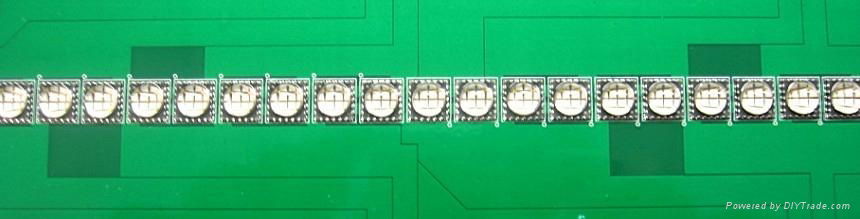

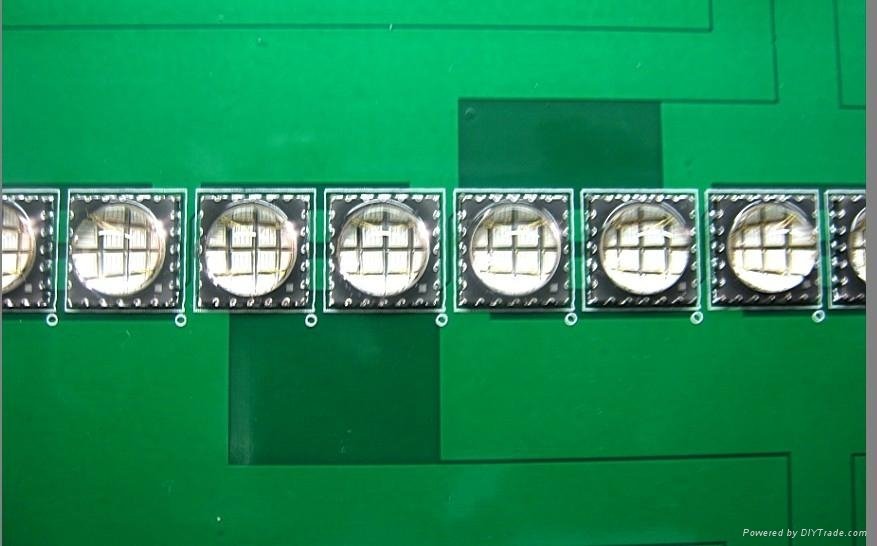

| Label: | 710nm IR LED , 760nm infrared light , 1330nm IR LED |

| Price: |

-

|

| Min. Order: | 100 pc |

Product Description

|

uv led curing equipement Datasheets: 1) Emitting Window:710*15mm

2) UV LED Power: Up to 1.2KW

3) Total Power: Below 3.5KW

4) UV intensity: 2W/cm2

5) Area control: 4 areas

6) Output Dimmer: Stepless

7) Cooling system: Cool water or Compressor

8) Interface Control: PLC+LCD

9) Safety: CE, RoHS

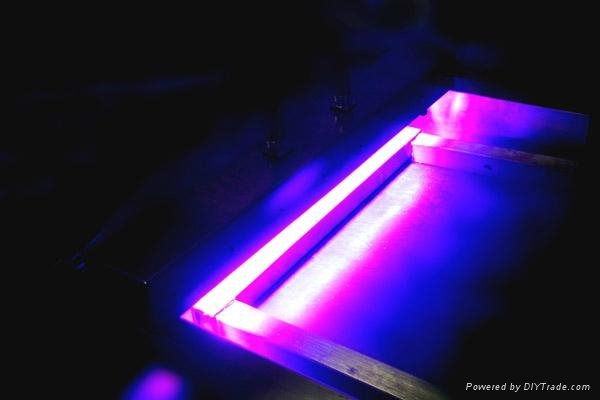

LED technology in the use of UV curing inkjet printers becoming more common, LED technology can replace the traditional high-pressure mercury lamp, no heat radiation, low energy consumption, long life, low cost, efficient, safe and green. Main features:

|

Member Information

| Shanghai Yuli Technology Co.,Ltd | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 13917875691 |

| Contact: | Luna Tang (sales) |

| Last Online: | 14 Jul, 2017 |

Related Products of this Company

-

UV led curing equipment for EPSON DX5

US $1600

-

High Performance Water-cooled LED UV

US $1600

-

UV led curing machine for flatbed EPSON

US $1600

-

High flux DIP 375nm uv light in

US $1

-

High Performance uv led 365nm/375nm

-

High flux 3mm DIP 375nm uv light

US $1

-

High flux 365nm 375nm 385nm 395nm uv led

-

High Performance 365nm/375nm/385nm/395nm

-

High power 280nm deep uv led for

-

High radiant 8w/cm2 16w/cm2 inkjet uv