| Model: | NTS-050CTi-U |

|---|---|

| Brand: | NANTAI |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | Titanium threaded pi , Tube heat exchanger , Titanium tube heat e |

| Price: |

¥2500

/ pc

|

| Min. Order: | 1 pc |

Product Description

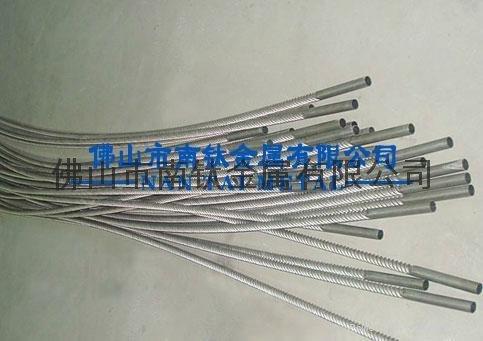

Titanium threaded coaxial tube heat exchanger: with two different size the standard pipe connected concentric circles casing outside called the shell (304 seamless pipe / titanium tube light), the internal called the tube side (titanium threaded pipe). Two different media can be in the shell and tube countercurrent flow (or in the same direction) in order to achieve the effect of the heat exchanger.

The titanium threaded pipe through a special process with enhanced heat transfer tube of the double-sided garter corrugated channel. Titanium threaded pipe has good corrosion resistance, high reliability, long life, and economic rationality. Increases titanium threaded pipe tube heat exchanger shell and tube heat exchanger temperature, pressure, flow, thermal load, general requirements, design and processing technology is mature, can be used for some kind of corrosive medium conditions. The most prominent advantage of the heat exchanger of the the titanium threaded pipe casing can force the fluid to flow through the tube bundle, so that the degree of fluid turbulence continued to be strengthened to achieve the purpose of heat transfer enhancement prescribed path many times wrong.

Titanium tube heat exchanger of the main features:

1, a high heat transfer efficiency

Continuous heat exchange tube threaded pipe, pipe flow channel cross section mutations causing fluid, even in the case of a very low flow rate is also always in a highly turbulent state, it is difficult to form a laminar flow and convective heat thermal resistance effectively overcome tube inside and outside heat transfer enhancement, and thus a high heat transfer coefficient, usually traditional light tube heat exchanger 2 to 3 times.

2, the ability of anti-fouling:

So that particles in the fluid is difficult due to the high turbulence of the fluid within the flow channel, deposition of fouling, even with a small amount of scale formation on the wall, since the medium in the pipe internal and external turbulent flow, erosion strongly anti-fouling ability. Further, the threaded tube exists strain generated due to the stress of the temperature difference between the inner tube and the outer tube, so that the curvature of the tube of the thread has elastic characteristics the occurrence of microscopic changes, so that the threaded tube heat exchanger has the ability of antifouling and descaling.

3, the ability of stress compensation

Threaded tube because of their structural shape and characteristics of the thin wall, the inner tube and the outer tube temperature stress larger, having elastic characteristics of curvature of the threaded tube microscopic changes occurred to compensate for the elimination of thermal stress, and effectively prevent the traditional the pipe heat exchanger heat transfer tubes easily crack such phenomena.

4, compact structure, small and light

The threaded pipe heat exchanger heat transfer coefficient is very high, the required heat transfer area, and threaded pipe wall thickness is thin, threaded tube heat exchanger structure is compact, small and light.

It should be noted that the use of titanium tube heat exchanger question:

1, selected for specific situations. The titanium threaded pipe heat exchanger conditions, tube passes (titanium threaded pipe) and the shell (304 seamless steel pipe) pressure of about 30 to 40KG.

2, poor earthquake resistance of the titanium tube heat exchanger tube bundle, transportation and hoisting shall not be excessive collision. ;

Titanium tube heat exchanger is running about 10 months should be shut down once easy to threaded pipe contraction recovery. The contraction of the threaded tube is also conducive to the peeling of the dirt.

The titanium threaded pipe through a special process with enhanced heat transfer tube of the double-sided garter corrugated channel. Titanium threaded pipe has good corrosion resistance, high reliability, long life, and economic rationality. Increases titanium threaded pipe tube heat exchanger shell and tube heat exchanger temperature, pressure, flow, thermal load, general requirements, design and processing technology is mature, can be used for some kind of corrosive medium conditions. The most prominent advantage of the heat exchanger of the the titanium threaded pipe casing can force the fluid to flow through the tube bundle, so that the degree of fluid turbulence continued to be strengthened to achieve the purpose of heat transfer enhancement prescribed path many times wrong.

Titanium tube heat exchanger of the main features:

1, a high heat transfer efficiency

Continuous heat exchange tube threaded pipe, pipe flow channel cross section mutations causing fluid, even in the case of a very low flow rate is also always in a highly turbulent state, it is difficult to form a laminar flow and convective heat thermal resistance effectively overcome tube inside and outside heat transfer enhancement, and thus a high heat transfer coefficient, usually traditional light tube heat exchanger 2 to 3 times.

2, the ability of anti-fouling:

So that particles in the fluid is difficult due to the high turbulence of the fluid within the flow channel, deposition of fouling, even with a small amount of scale formation on the wall, since the medium in the pipe internal and external turbulent flow, erosion strongly anti-fouling ability. Further, the threaded tube exists strain generated due to the stress of the temperature difference between the inner tube and the outer tube, so that the curvature of the tube of the thread has elastic characteristics the occurrence of microscopic changes, so that the threaded tube heat exchanger has the ability of antifouling and descaling.

3, the ability of stress compensation

Threaded tube because of their structural shape and characteristics of the thin wall, the inner tube and the outer tube temperature stress larger, having elastic characteristics of curvature of the threaded tube microscopic changes occurred to compensate for the elimination of thermal stress, and effectively prevent the traditional the pipe heat exchanger heat transfer tubes easily crack such phenomena.

4, compact structure, small and light

The threaded pipe heat exchanger heat transfer coefficient is very high, the required heat transfer area, and threaded pipe wall thickness is thin, threaded tube heat exchanger structure is compact, small and light.

It should be noted that the use of titanium tube heat exchanger question:

1, selected for specific situations. The titanium threaded pipe heat exchanger conditions, tube passes (titanium threaded pipe) and the shell (304 seamless steel pipe) pressure of about 30 to 40KG.

2, poor earthquake resistance of the titanium tube heat exchanger tube bundle, transportation and hoisting shall not be excessive collision. ;

Titanium tube heat exchanger is running about 10 months should be shut down once easy to threaded pipe contraction recovery. The contraction of the threaded tube is also conducive to the peeling of the dirt.

Member Information

| FoShan NanTi Metal Co., Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13827761325 |

| Contact: | li (Sales manager ) |

| Last Online: | 04 Jul, 2019 |