| Model: | H-TC200MC |

|---|---|

| Brand: | KC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Plate Making & Printing Machine |

| Label: | heat transfer machin , shoe-pad machine , hot stamping machine |

| Price: |

US $4848

/ pic

|

| Min. Order: | 1 pic |

Product Description

Hydraulic flat heat transfer machine for snowboards:

Snowboards

Snowboards have a large area and a relatively flat surface. Hydraulic flat heat transfer machines can clearly transfer various exquisite patterns, such as snowflakes, animals, geometric figures, etc., to the surface of snowboards, meeting the needs of different consumers for personalization and beauty, while also improving the overall quality and market competitiveness of snowboards.

Scooters

The body, pedals and other parts of scooters are suitable for printing with hydraulic flat heat transfer machines. Some trendy elements, brand logos, cartoon images and other patterns can be transferred to make scooters more personalized and fashionable, attracting more consumers, especially young people.

Surfboards

Surfboards come in a variety of shapes and sizes, but generally have a large flat area for transferring patterns. Hydraulic flat heat transfer machines can vividly transfer patterns related to the ocean and surfing culture, such as waves, dolphins, surfers, etc., to surfboards, which not only increases the beauty of the surfboards, but also reflects the personality and style of the surfers.

Household appliance panels

Household appliance panels need to have good appearance and durability. Hydraulic flat thermal transfer machines can accurately transfer various beautifully designed patterns, texts, symbols, etc. to the panels, such as energy efficiency logos and brand logos on refrigerator panels, function button logos on microwave oven panels, etc., which can not only improve the decorativeness of the panels, but also enhance their wear resistance and corrosion resistance, and extend their service life.

Hydraulic thermal transfer machine

Hydraulic thermal transfer machines mainly use heat and pressure to sublimate or melt the ink on the transfer paper, and then transfer it to the surface of the substrate. When working, the transfer paper is attached to the substrate such as skis and household appliance panels, and pressure is applied through the hydraulic system, while the heating system increases the temperature. Under the action of high temperature and high pressure, the ink molecules of the pattern or text on the transfer paper sublimate or melt, penetrate into the surface of the substrate, and form a solid pattern after cooling.

Structure

• Hydraulic system: It is composed of an oil pump, an oil cylinder, a piston and an oil pipe. The hydraulic oil is delivered to the oil cylinder through the oil pump, pushing the piston to generate pressure, ensuring that the transfer paper and the substrate are closely attached, and the pressure is uniform and adjustable.

• Heating system: It includes a heating cover, a thermostat, etc. The heat generated by the heating cover is radiated to the silicone roller. The thermostat can accurately control the surface temperature to ensure the transfer effect.

• Workbench: It is used to place the substrate, with a flat and smooth surface. Some are also equipped with a positioning device to ensure the accurate position of the substrate and facilitate transfer.

Features

• Good transfer effect: The hydraulic system provides stable and uniform pressure, combined with precise temperature control, so that the transfer pattern is bright in color, high in clarity and strong in adhesion.

• Wide range of applications: It can transfer flat objects of different materials and shapes such as skis and surfboards, which can meet a variety of printing needs.

• Flexible pressure adjustment: The hydraulic system can flexibly adjust the pressure according to the thickness and hardness of different substrates.

|

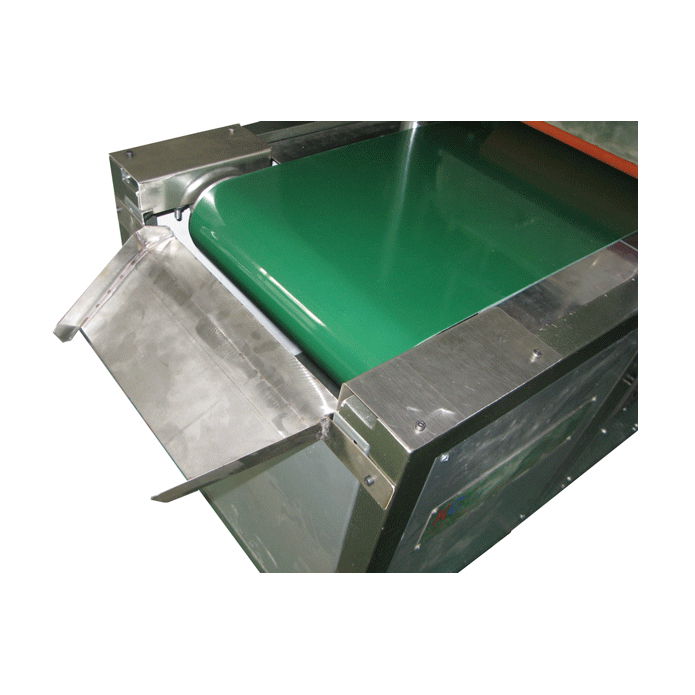

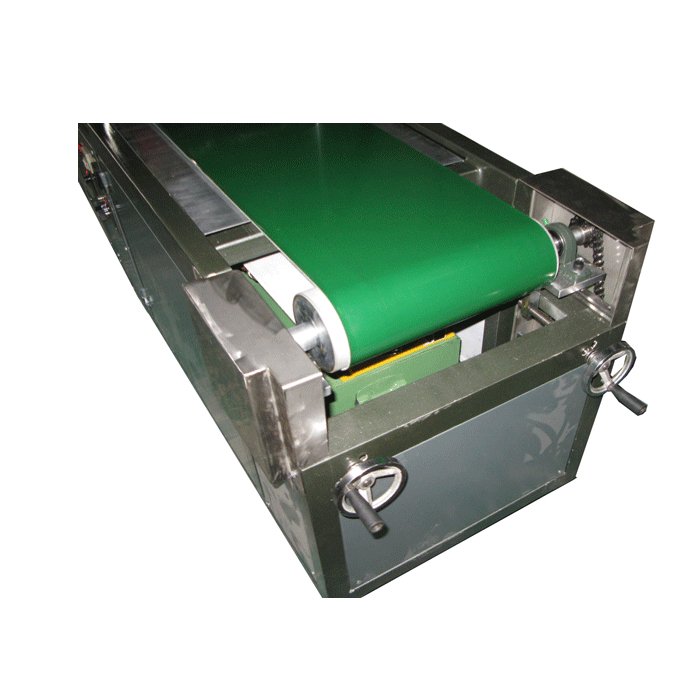

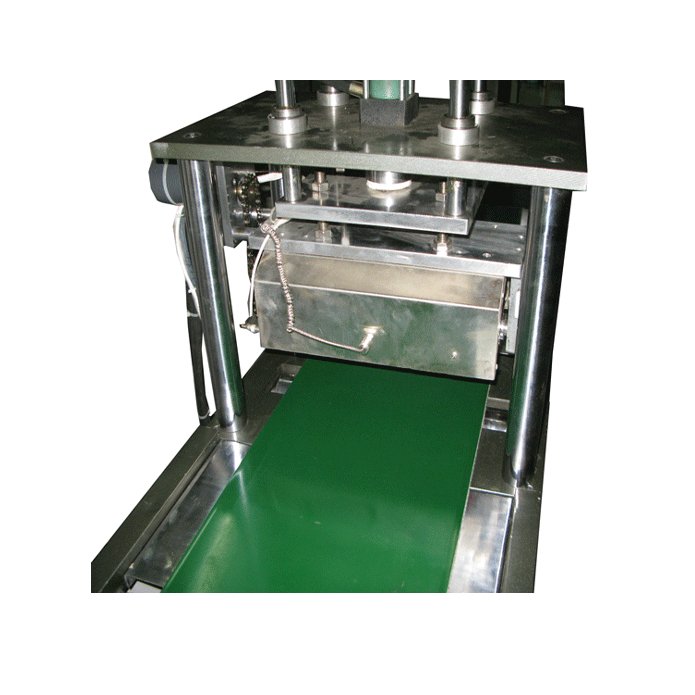

H-TC200MC Heat transfer Machine with transport conveyor //Structure |

||

|

Working table |

200mm width PVC Transmission belt ; |

|

|

Stamping Head drive |

Pneumatic drive |

|

|

Foil collecting method |

No. |

|

|

Press adjustment |

Up-down of stamping head |

|

|

Temperature control |

Heating tube heat up,Automatically temperature controlling, temperature free setting |

|

|

Stamping roller size |

Width: 200mm, diameter: 150mm. |

|

|

H-TC200MC heat transfer machine with transmission belt//Usage and characters |

||

|

Guide |

|

|

|

Application fields |

|

|

|

H-TC200MC heat transfer Machine with transmission belt //Parameter |

||

|

Technical parameters |

|

|

|

Works supply |

|

|

|

Package list |

|

|

|

||

|

H.S.Code |

8443198000 |

|

|

Certificate |

CE |

|

|

H-TC200MC heat transfer machine with transmission belt //Advantage |

||

|

Function |

|

|

Member Information

| Dongguan KC Printing Machine Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Kelven Bai (General manager) |

| Last Online: | 16 Jan, 2025 |

Related Products of this Company

-

High speed hot selling Automatic Pen-rod

US $10294

-

Communication equipment Precision

US $4600

-

PLC servo-rotating high accurate Sealed

US $4496

-

Flat tabletop screen printer with vacuum

US $1176

-

Color printing package hot stamping

US $11176

-

Servo helmet pad printing machine for

US $5100

-

Plastic flying disc hot stamping machine

US $5294

-

Flat UV Drying tunnel oven

US $2766

-

High accurate servo shuttle 4-color pad

US $8800

-

High accurate Electric circuit screen

US $4549