| polycarbonate sheet of WEIERSHA be formed with complete new pc sheet raw materials offered by Bayer Macrolon,GE lexan etc,contained anti-ultraviolet absorbent,adopting European co-extrusionand technology and equipments. |

Specification of PC sheet:

| Thickness |

0.8~2.5mm, can be by client . |

| Length |

sheet be 5.8,11.8m length,,can be by client either. |

| Width |

760mm,820mm,840mm,930mm,860mm,max to 1050mm,can be by client either. |

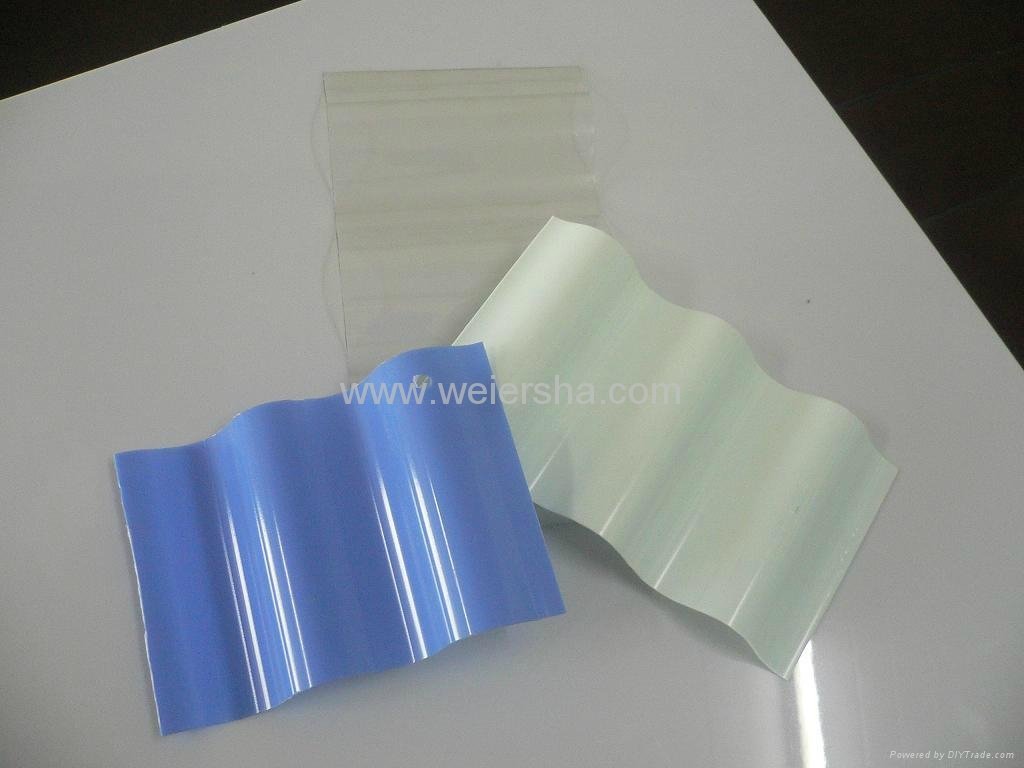

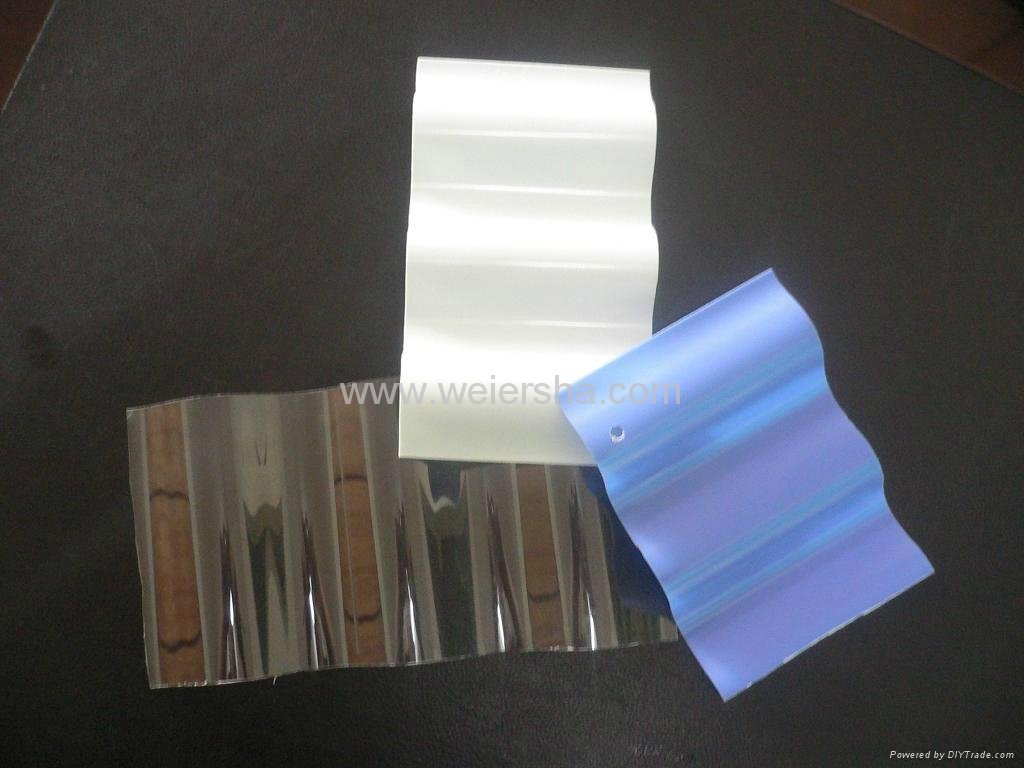

| Colour |

Clear,Transparent, Transparent-blue, Transparent-green, Coffee, Opal, can be by clients either. |

Polycarbonate sheet application

1-Day lighting for building roofing/wall;

2-Decorating,advertising, Display Design;

3-Sound insulation wall for expressway, environment;

4-Roofing/wall for agricultrure greenhouse,garden, plant and cultivate;

5-Part of machine,electron, household electrical appliances equipment.

PC sheet properties

Light transmission: Fine light transmitting rate approve to 30~ 85%.

Weather resistance: With anti-UV weather treatment on the surface, it can prevent the resin from fatigue and yellowing caused by UV. The anti-UV agent on the surface can change the UV absorbed by chemical bond into visible light, and finely stabilize the photosynthesis of plants.

Impact resistance: With the strength as 250 times of the ordinary glass,30 times as the PMMA sheet, it has less risk of breakage

Fire retardant: Fire retardency is up to B2 level(based on National GB8625-88 testing, without flame or toxic gas).

Temperature toleration: Without deformation within the temperature range from-40°C to +120°C.

Sound insulation: It is the best transparent materials for sound insulation engineerings as expressways,factories,etc..

Portability: Easy for handling and drilling,wo't be breakage whencutting, simple and easy be treated in using.

Notice When transporting, storing,installation:

· Keep PC panels away from wet cement surface or any alkaline/acid base materials.

· Keep frame clean and jointing groove flat and smooth.

· Use neutral glass cement and right gasket. Never use gasket of PVC material.

· Use electrical tools(tungsten carbide saw)to cut,stabilize PC panels to prevent their vibration.

· Choose right thickness of PC panels,allow flexure radius.

· Remain space for expanding,pay attention to inserting depth.

· In case that marks have to be made before cutting,try to mark on protective film;If the marks must be made directly on PC panels,use wax crayon instead of any sharp tool to mark.

· Never pill off protective films until installation is completed.

· Drilling and fixed:

If use self –drilling screws for fixing,the hole must be pre-drilled,the aperture should be 1,5 times larger than the diamenter of the screw,it is s ested to use roof hook for fixing.Do not tighten the screw strongly,otherwise stress will arise,and local crack on the sheet surface will appear.

· About purline span:

For the sheet 1.0mmthick,the span of purline is s ested to be less 1000mm.

For the sheet 1.2mmthick,the span of purline is s ested to be less 1200mm.

For the sheet 1.5mmthick,the span of purline is s ested to be less 1500mm.