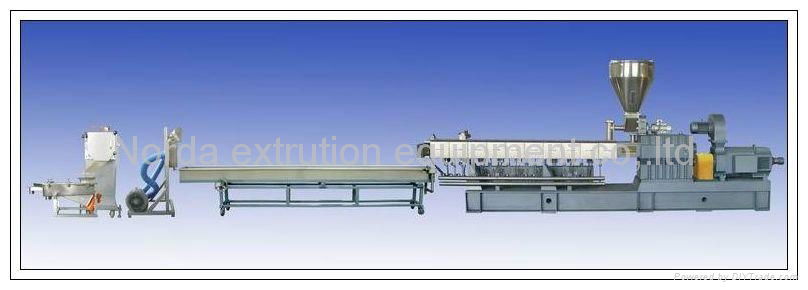

| Model: | SHJ |

|---|---|

| Brand: | Norda |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | EXTRUDER , twin screw extruder , pelletizer |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

SHJ 65 technical data

Twin screw length diameter ratio 40:1

Twin screw motor power 75KW DC

Second, the unit configuration

A, SHJ 65 twin screw compounding extruder

A, gear reduction box

B, oil cooling system

C, host motor

1) host motor: 75KW (DC motor)

2) motor speed (MAX): 1500RPM

D, screw

1) screw diameter: 62.4mm

2)L/D= 40:1

3) screw is the building block type

4) screw mandrel 40CrNiMoA materials, linked the mandrel and screw element for involute, high strength, bearing loads, easy disassembly and assembly combination.

5) screw W6MO5Cr4V2 components made of high quality, high-speed tool steel, high temperature vacuum quenching heat treatment.

6) overall hardness HRC62~64.

E : barrel

1) barrel material selection for 45 steel substrate, eight holes with two alloy bushings, wear-resistant alloy a-101 (Fe-Cr-Ni-B+Carbide) hardness HRC60-64, barrel length L=240mm/section.

2) section I tube for feeding tube, tenth section cylinder to cylinder of extruder, remaining closed shell of the cylinder.

3) soft water circulation system

3.1 in the barrel with a soft water cooling

3.2 soft water tank and the separation of the body, easy cleaning and maintenance

3.3 Italy imports solenoid valve

3.4 mains copper plated by chrome treatment

3.5 cooling way: water cooling

3.6 cooling pump: 0.55KW

3.7 water tank capacity: ~120L

F, heating system

By melt thermal galvanic material melting temperature measuring, measuring material pressure with pressure sensors.

H, vacuum degassing device

J, electrical control system

1, 3X380V, AC 50Hz.

2, the main electrical control components are Siemens products

3, the control button for France Schneider

4, twin screw motor DC motor power 75KW, double screw extruder speed adjusting device for the United Kingdom continental Governor

5, feeder speed adjusting device for the imported frequency conversion speed regulator

6, temperature controller adopts Japan RKC products, dual-channel intelligent, temperature control in each district.

7, pressure gauge range as 0~25Mpa

8, electromagnetic valve Italy imports solenoid valve CEME9313

9, heating controlled by the temperature-controlled table through the solid state relay

10, electrical control cabinet control include: temperature-controlled system; drive; interlocking control system

K, interlock control system

B, earnest auxiliary set

C, spare

Three, training and services

1, provide on-site installation guide

2, equipment at the scene deb ing test

3, responsible for the training of party a personnel site operation and maintenance training

4, equipment failure due to design or manufacturing quality provide one year free warranty, and long-term guaranteed spare parts supply.

5, long-term provision of technical advisory services

6, inside and outside the warranty period, for the parties to answer demand-side device fault notification, give a clear solution within 6 hours, if required for officers, should be responsible for maintena

nce in less than 10 hours to the scene (not including travel time in the middle).

Four, installation deb ing: unit after arrival, demand-side supply-side technical file allows installation in place, the supplier is commissioning officers to attend the demand side device installation site is responsible for commissioning and installation and commissioning. Demand side should have the test conditions. After the unit's normal operation, namely transfer, demand-side user acceptance report should be provided to the supplier. Material provided by the required party needed to test, test conditions dominated by demand-side, the parties agreed.

Five, technical one.

Member Information

| EASY ELECTRONIC CO.,Ltd | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 18251888912 |

| Contact: | catherine (sales manager) |

| Last Online: | 10 Feb, 2012 |