| Model: | - |

|---|---|

| Brand: | Dongjian |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

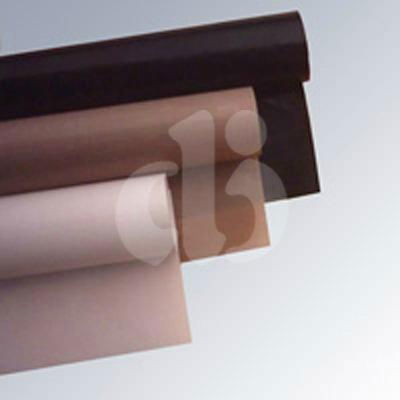

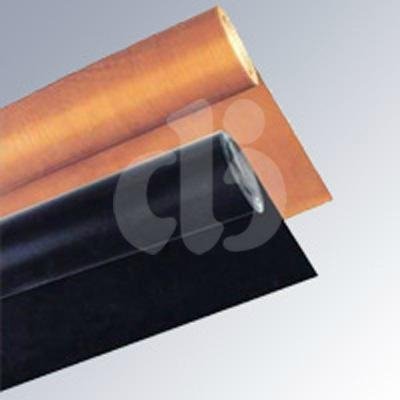

| Label: | Teflon cloth , welding cloth , teflon/ptfe |

| Price: |

US $5.8

/ sm

|

| Min. Order: | 1 sm |

Product Description

PTFE Coated Glass Fabrics are high performance materials used in a wide range of applications.

PTFE coated materials offer a non stick surfaces with excellent resistance to extremes of temperatures.

Applications:

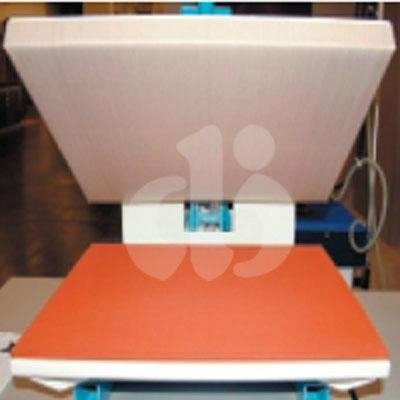

PTFE coated glass fabrics are used in a wide verity of industries and applications.

Packaging – PTFE adhesive tapes.

Printing – Open weave mesh belting.

Textiles – Closed weave and mesh belting.

UPVC window welding – Non and self adhesive materials.

Features / Benefits:

The properties of the PTFE coated materials ensure that the fabrics are an excellent choice for use with cooling chambers and freezing temperatures as well as high thermal environments. The PTFE is coated on to either a fiber glass or Kevlar substrate. Both substrates offer high levels of temperature resistance however the Kevlar can be beneficial in applications where strength is required or where steam is present.

Material Properties:

Temperature resistance: -70°C up to plus 260°C

Chemical inertness: affected only by a few rare substances at very high temperatures

High release from sticky materials ‘non-stick’

Easy cleaning (nothing bonds permanently)

Low friction coefficient: 0.04 - 0.10; depending on load and surface speed

Chemical corrosion and moisture resistance

Mildew and fungus resistance

Outstanding electrical, insulative and di-electric properties

Ultra-violet, Infra-red, microwave & radio frequency resistance

Non combustible - self extinguishing

Low thermal expansion: < 5%

Lightweight and energy efficiency for economical operation

Additional Information:

PTFE coated fabrics tend to be offer as either slit rolls in adhesive backed form, sheet rolls in non adhesive or converted to specialist bespoke conveyor belting. Material widths can vary from but can be offered up to 4000mm wide depending on the grade or requirement.

Member Information

| Jiangsu DongJian Hi-Tech Materials Co., Ltd | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 18951157686 |

| Contact: | Nickole Zhou (Manager) |

| Last Online: | 30 Oct, 2012 |