| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | Nano-plating machine |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Product Description

The latest environmentally friendly nano-plating system

Replace all the disadvantages of conventional plating.

For more information, please contact us. Video Click

Nano-coating with the social environment of enhanced environmental awareness, to develop environmentally friendly products in order to truly promote economic development, environmental protection and any expense of the development of a waste of resources can only be short-lived development. To all enterprises, the whole society appeal: Let us save our resources, to safeguard our environment, to become the "green economy" and follow the development and environmental "win-win" way.

After three years of research and two years of practice, and finally opened a new chapter in history - environmental nano coating technology was born! Since then, human beings can say goodbye to the traditional plating process to bring a series of hazards, from pollution!

In the surface treatment industry, environmental protection, nano-coating much favor the industry, plus it has broad applicability, environmental protection, technological innovation, solid practicality, great value and quality advantages, and thus attention by all walks of life, its economic efficiency is remarkable!

First, the environmental principles of nano-coating process:

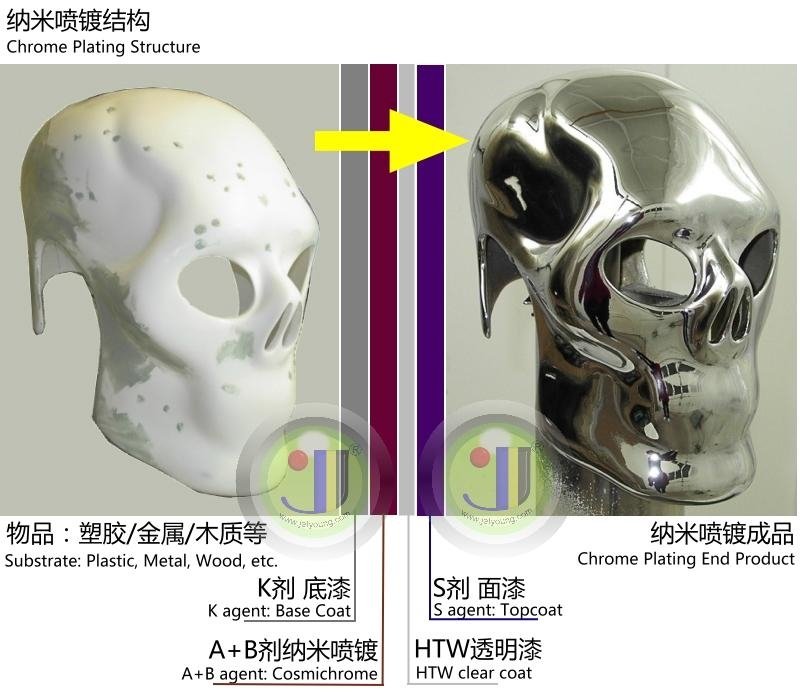

Environmental nanotechnology coating process works: the use of special equipment and specific materials, the application of principles of chemical reactions to achieve by way of direct spray plating results, the object being sprayed surface showed Chrome, Nickel, sand nickel, gold, silver, copper and various color (red, yellow, purple, green and blue) color gradient effects such as specular highlights.

Second, environmental nanotechnology coating process:

Pre-treatment (degreasing of oil, there is rust rust) → spray primer (the primer can be active guests) → drying → environmental reaction layer nano-coating spray equipment, spray paint → (guests are available with the primer) → drying → product packaging

Third, the scope of environmental nanotechnology coating:

Broad applicability: metal, resin, plastic, glass, ceramics, acrylic, wood, wood, magnesium, calcium plastic, cement and other materials. Can be widely used in automobiles, electrical appliances, handicrafts, computer phones, accessories, luxury furniture and other surface decoration, which can be more new industry was born.

Fourth, the product features:

Environmental protection: environmental protection, no heavy metals, the production process without waste emissions, green tech is a safe spraying.

Technological innovation: the first generation of process technology is more than simple, lower cost, can be targeted spraying, the product can do the same fork in the color coating.

Conclusive practical: processed products from a variety of material constraints, not the volume, size, shape constraints, various colors, arbitrary.

Great efficiency of: non-conductive products do not need conductive layer, lower cost, higher profit; according to customer demand and product diversification, operating environment and operating conditions, etc., to provide suitable mass production operation automated assembly line.

The stability of investment: low investment, high return, low cost, no risk.

Quality advantages: excellent adhesion, impact resistance, corrosion resistance, weather resistance, abrasion resistance and scratch resistance, good anti-rust performance.

Fifth, environmental protection advantages of nano-coating technology:

1, equipment improvements:

⑴ equipment for the split type design, the back and spraying machine penetration machine easy to operate after the use of separate design.

⑵ set aside two rows of spray interface, with easy access in case of increased production for equipment upgrades.

⑶ improved special gun lighter, better atomization, thus reducing material consumption.

2, technological innovation:

⑴ technological innovation through the actual production will decrease after the original process of two processes, reduce material consumption and reduce costs.

⑵ operation process easier, as follows: three spray two baking, quick-drying products do not reflect the level of baking.

⑶ fully break the limitations of the paint, regardless of any paint or powder coating can be sprayed with nanotechnology and environmental protection.

Sixth, environmental protection authority of nano-spray test:

1, the company has passed the SGS RoHS Test (Test Report Number: TJTC0705916/CHEM), without (Cd Cd, Pb Pb, Hg Hg, hexavalent chromium CrVI, polybrominated biphenyls PBBs, polybrominated diphenyl ethers PBDEs), exports to the European standards.

2, has passed the authority of the National Chemical Building Materials Test Center testing (test report number: BETC-HJ-P-235). Press the "film chemical resistant test approach," "Determination of water-resistant paint", "Paints and varnishes cross-cut test." Test results are:

No abnormal water resistance -48 hours

Alkali (2% NaOH solution) 48 hours without exception

Adhesion (cross-pitch 1mm) without loss

4, has passed the non-ferrous metals and electronic materials, salt spray test Test Center (Test Report Number: 2006002736E). By GB/T10125, GB/T6461 standard testing. The results for the neutral salt spray test 180 hours by 9.8.

5, has passed the national building materials testing center of weathering and acid resistance tests

The latest environmentally friendly nano-plating system

Replace all the disadvantages of conventional plating.

For more information, please contact us. Video Click

Nano-coating with the social environment of enhanced environmental awareness, to develop environmentally friendly products in order to truly promote economic development, environmental protection and any expense of the development of a waste of resources can only be short-lived development. To all enterprises, the whole society appeal: Let us save our resources, to safeguard our environment, to become the "green economy" and follow the development and environmental "win-win" way.

After three years of research and two years of practice, and finally opened a new chapter in history - environmental nano coating technology was born! Since then, human beings can say goodbye to the traditional plating process to bring a series of hazards, from pollution!

In the surface treatment industry, environmental protection, nano-coating much favor the industry, plus it has broad applicability, environmental protection, technological innovation, solid practicality, great value and quality advantages, and thus attention by all walks of life, its economic efficiency is remarkable!

First, the environmental principles of nano-coating process:

Environmental nanotechnology coating process works: the use of special equipment and specific materials, the application of principles of chemical reactions to achieve by way of direct spray plating results, the object being sprayed surface showed Chrome, Nickel, sand nickel, gold, silver, copper and various color (red, yellow, purple, green and blue) color gradient effects such as specular highlights.

Second, environmental nanotechnology coating process:

Pre-treatment (degreasing of oil, there is rust rust) → spray primer (the primer can be active guests) → drying → environmental reaction layer nano-coating spray equipment, spray paint → (guests are available with the primer) → drying → product packaging

Third, the scope of environmental nanotechnology coating:

Broad applicability: metal, resin, plastic, glass, ceramics, acrylic, wood, wood, magnesium, calcium plastic, cement and other materials. Can be widely used in automobiles, electrical appliances, handicrafts, computer phones, accessories, luxury furniture and other surface decoration, which can be more new industry was born.

Fourth, the product features:

Environmental protection: environmental protection, no heavy metals, the production process without waste emissions, green tech is a safe spraying.

Technological innovation: the first generation of process technology is more than simple, lower cost, can be targeted spraying, the product can do the same fork in the color coating.

Conclusive practical: processed products from a variety of material constraints, not the volume, size, shape constraints, various colors, arbitrary.

Great efficiency of: non-conductive products do not need conductive layer, lower cost, higher profit; according to customer demand and product diversification, operating environment and operating conditions, etc., to provide suitable mass production operation automated assembly line.

The stability of investment: low investment, high return, low cost, no risk.

Quality advantages: excellent adhesion, impact resistance, corrosion resistance, weather resistance, abrasion resistance and scratch resistance, good anti-rust performance.

Fifth, environmental protection advantages of nano-coating technology:

1, equipment improvements:

⑴ equipment for the split type design, the back and spraying machine penetration machine easy to operate after the use of separate design.

⑵ set aside two rows of spray interface, with easy access in case of increased production for equipment upgrades.

⑶ improved special gun lighter, better atomization, thus reducing material consumption.

2, technological innovation:

⑴ technological innovation through the actual production will decrease after the original process of two processes, reduce material consumption and reduce costs.

⑵ operation process easier, as follows: three spray two baking, quick-drying products do not reflect the level of baking.

⑶ fully break the limitations of the paint, regardless of any paint or powder coating can be sprayed with nanotechnology and environmental protection.

Sixth, environmental protection authority of nano-spray test:

1, the company has passed the SGS RoHS Test (Test Report Number: TJTC0705916/CHEM), without (Cd Cd, Pb Pb, Hg Hg, hexavalent chromium CrVI, polybrominated biphenyls PBBs, polybrominated diphenyl ethers PBDEs), exports to the European standards.

2, has passed the authority of the National Chemical Building Materials Test Center testing (test report number: BETC-HJ-P-235). Press the "film chemical resistant test approach," "Determination of water-resistant paint", "Paints and varnishes cross-cut test." Test results are:

No abnormal water resistance -48 hours

Alkali (2% NaOH solution) 48 hours without exception

Adhesion (cross-pitch 1mm) without loss

4, has passed the non-ferrous metals and electronic materials, salt spray test Test Center (Test Report Number: 2006002736E). By GB/T10125, GB/T6461 standard testing. The results for the neutral salt spray test 180 hours by 9.8.

5, has passed the national building materials testing center of weathering and acid resistance tests

Member Information

| JetYoung Int'I Technolgy Co.,Ltd | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Services or Others |

| Phone: | 13530347720 |

| Contact: | Lisa (Business) |

| Last Online: | 05 Apr, 2012 |