| Model: | - |

|---|---|

| Brand: | ALUCOTAL |

| Origin: | Made In China |

| Category: | Construction & Decoration / Decoration Materials / Aluminum Composite Panel |

| Label: | aluminum cladding , aluminum panel , aluminum sheets |

| Price: |

-

|

| Min. Order: | - |

Product Description

Introduction

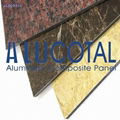

The panel consists of two sheets of corrosion resistant aluminum permanently bonded to polyethylene core material. The front aluminum coats PVDF (fluororesin) paint. Because of its excellent weather proof and other features, the panel becomes a very popular Cladding material in the world.

PVDF Coating

Fluorocarbon Aluminum composite panel is made of a mixture of fluorocarbon resin with fluorine enzyme as the basic monomer, paint, alcohol ester solvent and accessory ingredients. The molecular structure in the coating is compact after being high baked into film formation, which has extra-strong weather resistance. The fluorocarbon coating falls into conventional fluorocarbon coating.

Conventional fluorocarbon is made of KYNAR500 fluorocarbon and is solidified into film formation on the surface after three coats and three bake. It is acid & alkali resistant, standing the test of severe environment, and has no abnormal depigment for 15 to 20 years, which is more applicable for exterior decoration of architectures and curtain wall decoration of major constructional projects that have high demand for weather resistance.

Feature

Light weight, high strength, extreme rigidity, superior impact resistance, excellent surface flatness and smoothness , heat insulation, sound insulation, fire-resistance, acid-resistance, alkali-resistance, good weatherproofing and non-resonance ,various uniform colors ,can be easily processed and fabricated, quickly installed, elegant and magnificent, good flexibility fits various designs, easily maintenance, simply cleaning

Application

1) Constructional exterior curtain walls;

2) Decorative renovation for storey-added old buildings;

3) Indoors decoration for interior walls, ceilings, bathrooms, kitchens and balconies;

4) Advertisement board, shop face decorating, display platforms and signboards;

5) Wallboard and ceilings for tunnels; Circular columns

6) Raw materials in industrial purpose;

Member Information

| Shanghai Alucotal Decorative Material Co.,Ltd | |

|---|---|

| Country/Region: | Shang Hai - China |

| Business Nature: | Manufacturer |

| Phone: | 13701947365 |

| Contact: | Sang Wei (Sales Manager) |

| Last Online: | 04 Oct, 2014 |