DESCRIPTION

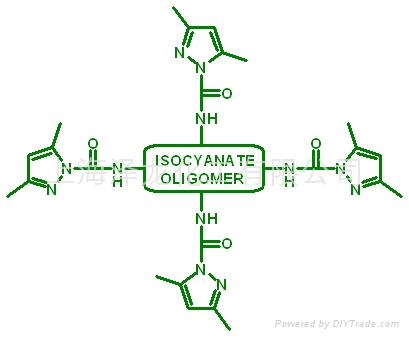

XC-327 is a type of blocked isocyanate crosslinker, it is stable at room temperature, even when mixed with polyols and only become reactive once the system is heated to an unblocking temperature(100-120 degree), this ability to formulate stable, one component systems gives the formulator the scope to develop products for more varied applications utilizing in the system of acrylic and polyurethan oil resins; It mainly can be used for automotive OEM, coil, textile, electrostatic spraying and electro-deposition applications all of which are readily adaptable to heat-curing systems.

SPECIFICATION

Appearance: pale yellowish liquid;

Total Solid (w/w ): 83.1%;

NCO Content (w/w): 9.62-10.02%;

Unblocking Temperature (°C): 100-120;

Viscosity, at 25°C: 3000-4000cps;

Specific Gravity at 25°C: 1.02-1.06g/ml;

Other Character: dissolution in normal organic solvents and dispersion in waterborn coating.

APPLICATIONAS

In the system water based printed paste, can improve the abrasion resistance and gloss finish, not formaldehyde appear;

In water based acrylic resin and polyurethane latex, increase cohesive strength after heat treatment;

In any water based latex containing –COOH, -OH, -NH2, improves the resin strength and abrasion resistance, after dry and heat treatment;

In water based cotton & terylene latex, increases water and oil resistance;

In vinyl coatings to reduce plasticizer migration and improve stain resistance;

In water based concrete sealers to improve abrasion resistance

Generally, in any water based resins, improve the water, detergent, solvent, chemical resistance and abrasion resistance, after heat treatment formulation.

In the automotive OEM, coil, textile, electrostatic spraying and electro-deposition applications all of which are readily adaptable to heat-curing systems.

TYPICAL APPLICATION AS CROSSLINKER

Method of Addition: XC-327 is added slowly and with good agitation, directly to the formulated coating system which the PH value must be controlled between 6-9;

Addition Levels. The level of XC-327 to add to the formulated system will depend on the coating system and the desired properties of the coating film. Most applications find use levels between 1% and 3% based on total resin amount. Higher levels, such as 5-25%, may yield higher solvent resistance and adhesion properties;

CONTAINER INFORMATION & STORAGE CONDITIONS

Available in 5kg or 20kg plastic drums; Store in room place with adequate ventilation; pot life is about 12 months.