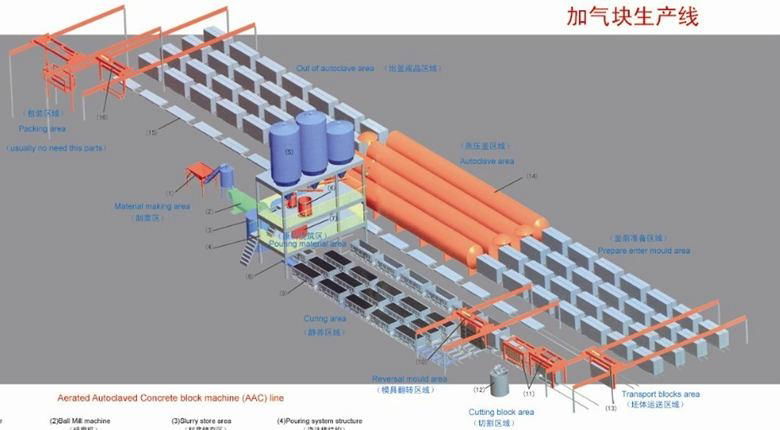

| Model: | AAC line |

|---|---|

| Brand: | HUALI MACHINERY |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | AAC block , AAC plant , automatic machine |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

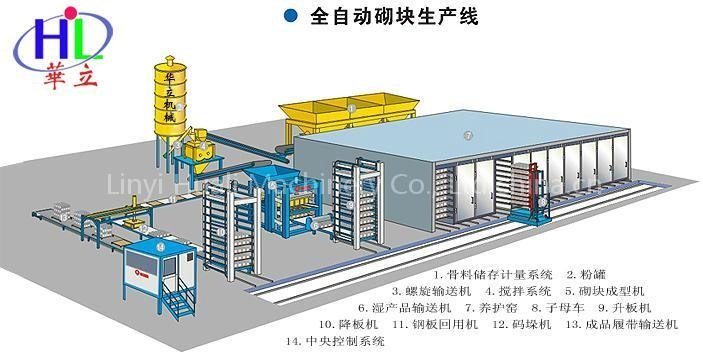

Production line:

The actual situation of each user according to specific analysis, targeted personalized design, specifically tailored for the customer to provide the most suitable equipment. Closed automatic production lines, advanced modular structure, and can be manual, linkage, automatic equipment operation, with a fully automated production line configuration of all excellent features.

Host Model: QT4-15, QT6-15, QT8-15, QT10-15, QT12-15.

Products: all kinds of wall block, block walls, wall displaying block, floor plates, berm blocks, can also produce interlocking blocks and curbs and other road blocks.

Application: widely used in construction, roads, squares, hydraulic engineering, landscaping and construction.

Raw materials: The sand, gravel, cement, can add a lot of fly ash, slag, steel slag, coal gangue, ceramic, perlite and other industrial waste.

Holley mechanical automatic block production line to provide major components: batching system, mixing systems molding system, transmission system, control system.

Series production line configuration:

A simple line of fully automatic batching, automatic mixing, automatic molding, manual transfer, artificial stacking

B automatic production line automatic batching, automatic mixing, automatic molding, automatic liter board, automatic drop plate, picture-car transport, pushing brick (or automatic palletizing), wet, dry product conveyor, flap machine, steel recycling machine

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

Ingredients, mixing system:

Years of successful design and manufacturing experience for Concrete Mixing highlighted ingredients, mixing system reliability. Dosing accuracy, balance owed automatic feeding, material measurement error ≤ ± 1%, to maintain accurate water-cement ratio. Twin-shaft compulsory stirring means in the impeller mixture under strong stirring, mixing upper and lower churn, and also around the axis perpendicular to the center to do around the movement of water in a short time to achieve the best mix of materials and uniformity.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

Forming system:

Each mode of production standard brick block are 4 ~ over 12 kinds of different mode vibration, Taiwan vibration molding machine to provide a strong exciting force, with full synchronization mode of vibration, harmonic excitation up to 120kN. Vibration source in the shape of the different process stages for the corresponding different vibration frequencies, different materials to achieve the best quality products.

Prototyping system by large-capacity hydraulic system, fuel tank body, oil filters, cooling devices, automatic voltage regulator variable system, high and low voltage control system, synchronous ejection device, vibration, compression device composed. Set or adjust the performance parameters is very convenient, you can normally produce different products. High reliability of hydraulic system, resulting in pressure, forming the product quality, and high strength.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

L trigger / drop trigger:

L trigger the transmission has been put in place two pallets molded concrete products, driven by the active chain wheel fixed on the pallet conveyor angle raise successive layer. Until the entire rack full of successive upgrading, the main control system will receive information and send commands to the picture-taking rose plate fork truck in place of the molding machine products.

Drop trigger plate machine up with the same structure of bomb car will go through a conservation conservation products kiln fork sent to board the plane down, child car quit, the lower plate machine in turn down a layer of bricks to the dry finished product conveyor line the shelves until the fall complete All finished brick.

Features: heavy structure, give full consideration to durability design, optimization details, so that more stable positioning pallets automatically placed.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

LASH car:

LASH car shuttle at the l board machine, kiln maintenance, reducing transmission between plate forming machine products. The wet product from the l board machine into the conservation of cross steam curing kiln drying, and from the conservation of kiln dried product to fork out the down board machine. Mother-board with his son on the car and along the horizontal rail molding products for linear movement along the mother of child car kiln cars and conservation track in a straight line of vertical movement.

Features: LASH car manufacturing precision, stable and reliable. Advanced control technology, with ingenious special positioning device, the mother in the running car, child car precise movement, accurate in the l trigger, conservation kiln, between the lower plate transfer molding machine. Running fast and smooth and efficient.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

Push brick:

Brick will push down plate conveying products in place to promote the transition platform based on the actual situation by hand and palletizing packages.

Features: Push brick by independent hydraulic circulatory system, pushing brick stable, accurate stroke, pushing brick plate return time is short.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

Stacker:

Stacker will dry product dry product from the conveyor line to crawl and move to the track conveyor wooden pallets for packing. Stacker gripper will turn vertical and horizontal fold the dry product, clamp and move to the desired location. On the device to ensure the product when the product is clamped homogeneous symmetric. Stacker, compact structure, manufacturing precision, accurate positioning and reliable operation.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

Production line control system:

Line with the central control system is an important core block production line.

Holley mechanical self-developed control system based on PLC + industrial control computer, with automatic, semi-automatic, manual of different models, to ensure uninterrupted production. Color animation production process simulation control interface, operation is practical. Non-contact position switches the use of travel and improve system reliability, and never wear. Reset the sensor and automatic high-precision measurement and control system, full automatic control of production, highlighting the high reliability, high stability, excellent features. This database system, ahead of the various statistical reports, print function. Automatic fault detection and alarm devices can be produced in advance of the test failure, a strong guarantee safety.

The actual situation of each user according to specific analysis, targeted personalized design, specifically tailored for the customer to provide the most suitable equipment. Closed automatic production lines, advanced modular structure, and can be manual, linkage, automatic equipment operation, with a fully automated production line configuration of all excellent features.

Host Model: QT4-15, QT6-15, QT8-15, QT10-15, QT12-15.

Products: all kinds of wall block, block walls, wall displaying block, floor plates, berm blocks, can also produce interlocking blocks and curbs and other road blocks.

Application: widely used in construction, roads, squares, hydraulic engineering, landscaping and construction.

Raw materials: The sand, gravel, cement, can add a lot of fly ash, slag, steel slag, coal gangue, ceramic, perlite and other industrial waste.

Holley mechanical automatic block production line to provide major components: batching system, mixing systems molding system, transmission system, control system.

Series production line configuration:

A simple line of fully automatic batching, automatic mixing, automatic molding, manual transfer, artificial stacking

B automatic production line automatic batching, automatic mixing, automatic molding, automatic liter board, automatic drop plate, picture-car transport, pushing brick (or automatic palletizing), wet, dry product conveyor, flap machine, steel recycling machine

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

Ingredients, mixing system:

Years of successful design and manufacturing experience for Concrete Mixing highlighted ingredients, mixing system reliability. Dosing accuracy, balance owed automatic feeding, material measurement error ≤ ± 1%, to maintain accurate water-cement ratio. Twin-shaft compulsory stirring means in the impeller mixture under strong stirring, mixing upper and lower churn, and also around the axis perpendicular to the center to do around the movement of water in a short time to achieve the best mix of materials and uniformity.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

Forming system:

Each mode of production standard brick block are 4 ~ over 12 kinds of different mode vibration, Taiwan vibration molding machine to provide a strong exciting force, with full synchronization mode of vibration, harmonic excitation up to 120kN. Vibration source in the shape of the different process stages for the corresponding different vibration frequencies, different materials to achieve the best quality products.

Prototyping system by large-capacity hydraulic system, fuel tank body, oil filters, cooling devices, automatic voltage regulator variable system, high and low voltage control system, synchronous ejection device, vibration, compression device composed. Set or adjust the performance parameters is very convenient, you can normally produce different products. High reliability of hydraulic system, resulting in pressure, forming the product quality, and high strength.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

L trigger / drop trigger:

L trigger the transmission has been put in place two pallets molded concrete products, driven by the active chain wheel fixed on the pallet conveyor angle raise successive layer. Until the entire rack full of successive upgrading, the main control system will receive information and send commands to the picture-taking rose plate fork truck in place of the molding machine products.

Drop trigger plate machine up with the same structure of bomb car will go through a conservation conservation products kiln fork sent to board the plane down, child car quit, the lower plate machine in turn down a layer of bricks to the dry finished product conveyor line the shelves until the fall complete All finished brick.

Features: heavy structure, give full consideration to durability design, optimization details, so that more stable positioning pallets automatically placed.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

LASH car:

LASH car shuttle at the l board machine, kiln maintenance, reducing transmission between plate forming machine products. The wet product from the l board machine into the conservation of cross steam curing kiln drying, and from the conservation of kiln dried product to fork out the down board machine. Mother-board with his son on the car and along the horizontal rail molding products for linear movement along the mother of child car kiln cars and conservation track in a straight line of vertical movement.

Features: LASH car manufacturing precision, stable and reliable. Advanced control technology, with ingenious special positioning device, the mother in the running car, child car precise movement, accurate in the l trigger, conservation kiln, between the lower plate transfer molding machine. Running fast and smooth and efficient.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

Push brick:

Brick will push down plate conveying products in place to promote the transition platform based on the actual situation by hand and palletizing packages.

Features: Push brick by independent hydraulic circulatory system, pushing brick stable, accurate stroke, pushing brick plate return time is short.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

Stacker:

Stacker will dry product dry product from the conveyor line to crawl and move to the track conveyor wooden pallets for packing. Stacker gripper will turn vertical and horizontal fold the dry product, clamp and move to the desired location. On the device to ensure the product when the product is clamped homogeneous symmetric. Stacker, compact structure, manufacturing precision, accurate positioning and reliable operation.

-------------------------------------------------- -------------------------------------------------- -------------------------------------------------- ------------------------------

Production line control system:

Line with the central control system is an important core block production line.

Holley mechanical self-developed control system based on PLC + industrial control computer, with automatic, semi-automatic, manual of different models, to ensure uninterrupted production. Color animation production process simulation control interface, operation is practical. Non-contact position switches the use of travel and improve system reliability, and never wear. Reset the sensor and automatic high-precision measurement and control system, full automatic control of production, highlighting the high reliability, high stability, excellent features. This database system, ahead of the various statistical reports, print function. Automatic fault detection and alarm devices can be produced in advance of the test failure, a strong guarantee safety.

Member Information

| LINYI HUALI MACHINERY CO.,LTD, | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13676399155 |

| Contact: | bryan.kwok (sales manager) |

| Last Online: | 25 Jun, 2012 |