| Model: | M3T/ M4T |

|---|---|

| Brand: | JINMING Machinery |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | Jinming blown film , geomembrane film , geomembrane extruder |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

Geomembrane film is widely used in refuse landfill, roads and bridge projects, tunnels, green projects, sewage ponds and similar construction projects.

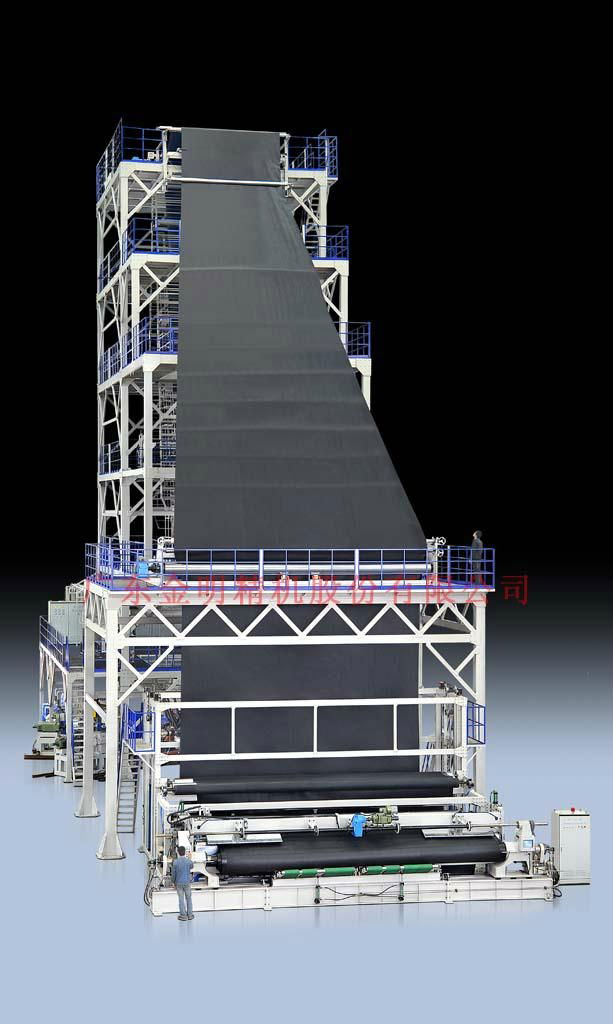

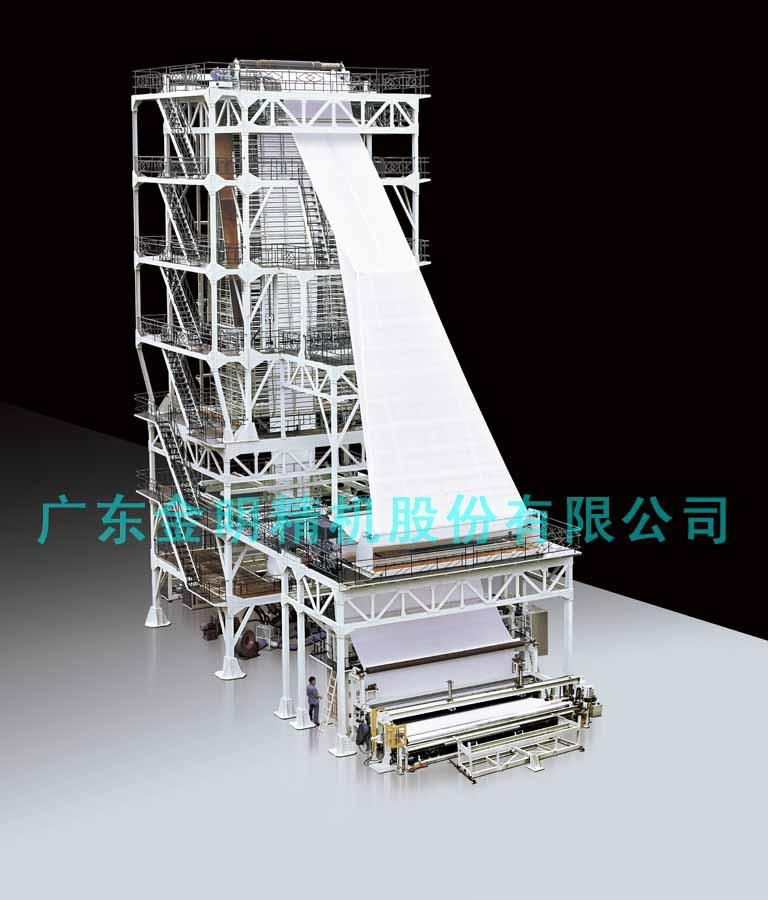

Because the surface of traditional geomembrane film is very smooth, its coefficient of friction is so low that it’s easy to move when on the ground, especially when it is used in a ramp project. Textured geomembrane film, available exclusively on Jinming’s M3T Geomembrane Line doesn’t have this problem because of its rough surface.

The three-layer coextrusion geomembrane blown film line manufactured by Jinming can achieve a maximum film width up to 8 meters. It not only produces geomembrane film with a smooth surface, but also an optional rough surface. The three-layer coextrusion textured geomembrane film is produced in a one-step coextrusion molding process with good chemical resistance capability, good environmental stress crack resistance, low penetrability, and the ability to accommodate white, black, or other functional master batches according to a customer’s request.

Jinming three-layer coextrusion textured geomembrane blown film line allows users to produce geomembrane film with rough surface on a single side or double-side. Additionally, the width of the smooth edge of the film scan is adjusted for welding.

Film Width: 5000mm, 6000mm, 7000mm, 8000mm

Film Thickness: 0.5-2.5mm

Output Capacity: 600-1200kg/H (depends on machine width)

Member Information

| Guangdong Jinming Machinery Co., Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13415040226 |

| Contact: | Simeon Wang (Sales Representitive) |

| Last Online: | 12 Apr, 2013 |

Related Products of this Company

-

Guangdong Jinming Double-Bubble POF Heat

-

Guangdong Jinming 2-Layer Co-Extrusion

-

Guangdong Jinming Three-Layer

-

Three-Layer Co-Extrusion Blown Film Line

-

Multilayer Coextrusion Downward Water

-

Guangdong Jinming 3-Layer Coextrusion

-

Multilayer Co-Extrusion High Barrier

-

7-Layer Coextrusion Triple Bubble High

-

Guangdong Jinming 3-Layer Coextrusion

-

Three-layer Coextrusion Downward Water