| Model: | 200000 square |

|---|---|

| Brand: | BT |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | AAC block machine , brick machine , sand (fly ash) brick |

| Price: |

-

|

| Min. Order: | - |

Product Description

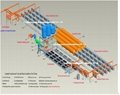

With an annual output of 200000 square aerated coagulation equipment production line process

With an annual output of 200000 square equipment aerated concrete and production technology

Medium-sized aerated concrete production line

The annual output of 200000 cubic aerated concrete production line mainly has: Material handling equipment, ingredients pouring equipment, static stop cutting equipment, marshalling maintenance equipment, finished out the reactor equipment, dust removal process equipment, electrical equipment and other related equipment, with a high degree of automation, easy operation, high yield etc...The use of air cutting technology, 4.2 meters distributed cutting unit, cutting process ( flip, slitting, die ) respectively in different work completed, and cutting, walking control in the same device, so that the work can be simplified, easy to operate and maintain.

Aerated concrete block production process

Aerated concrete equipment based on the raw materials category, quality, main process characteristics, adopt the different production process. But in general, the fly ash or sand adding water into a slurry, adding proper amount of powdered lime, cement, gypsum and a foaming agent, stirring after injection into the mold frame, static oxygen blowing after curing, cutting into a variety of specifications block or plate, by steam curing car into the autoclave in high temperature saturated steam curing condition, in the that the formation of porous light aerated concrete products.

Aerated concrete equipment production line of

According to the raw material category, quality, main process characteristics, adopt the different production process. But in general, sand aerated concrete is the river sand, lime, gypsum and cement as main raw material, foaming agent, stirring after injection into the mold frame, static oxygen blowing after curing, cutting into a variety of specifications block or plate, by steam curing car into the autoclave in high temperature saturated steam curing condition, in the form porous light sand aerated concrete products.

The annual output of 200000 cubic aerated concrete equipment configuration table

A raw material treatment equipment.

1 hopper 1

2 jaw crusher ( lime ) 1 PEF250 x 400

3 crushing machine chute 1

4 Bucket Elevator 1 IF4S x 21.35m

5 Bucket Elevator 1

6 corpus 1 Φ4.5× 8

7 manual screw gate 1 300 x 300

8 vibration feeder 1 Φ250 type

9 ball mill ( lime ) 1 Φ1830× 7000

10 screw conveyor 1 Φ250× S

11 Bucket Elevator 1 IF3S× 22m

12 bucket elevator chute 1

13 Manual disc brake 3

14 discharge pipes 1

15 slurry mixing tank 2 10m3

16 supplementary tank 1 V = 1m3

17 pneumatic blowing device 3

18 electric hoist 1 CD-1T

Two ingredients a pouring station equipment.

1 slurry meter 1 G = 700kg

2 slurry meter 1 Q = 3000kg

3 aluminum mixer 1 V = 0.052m3

4 electronic scales 1 ACS-15.15kg

5 single screw feeder 1 Φ250× 6m

6 casting mixer 1 V = 3.6m3

7 a ferry vehicle 1

8 electric hoist 1 CD-2T

Three static stop cutting process equipment.

1 mold 28 4.8 x 1.2 x 0.6

2 side plate 155 4.8 x 0.6

3 steam curing car 63 4.8 x 1.2 x 0.6

4 slow-motion hoist 2 JJM

5 guiding wheels 5

6 cutting and conveying mechanism 1 2 x 5.0t

7 reversal hanger 1

8 Distributed cutting unit 1 6m

9 beater ( shell ) 1 5.6m3

10 slurry pump of 1 80YZ80-20

11 side plate roller 12

Four. Equipment maintenance section marshalling

1 yards of blank conveying mechanism 1 2 x 5T

2 semi-finished spreader 1

3 vacuum pump 1 2SZ-6

4 kettle bridge 2 stations

5 autoclave 6 Φ2.68× 31.5m

6 waste water pool 1

7 liquid pump of 1 50YW30

Five finished product tank section equipment.

1. electric hoist ( including frame ) 1 ZDS1P = 5T

2 .out of 1 sets of autoclave spreader

3. out of 1 sets of tank car ferry

4. finished fixture 1

5 .hydraulic turning plate 1

6 .1 18 # light rail track

| six section. Dust removal equipment |

| 1 jaw broken single dust collector 1 DMC-48 |

| 2 warehouse roof ESP 3 HYF-2 |

| 3 mill outlet dust collector 1 LDMS50 |

| seven heating power pipeline. |

| 1 boiler of 2 SZL-1.6A II - 4 |

| 2 row tube radiator 14 D89 |

| 3 meter 1 A Niu DN125 |

| 4 Thermodynamic type steam trap 4 S49H |

| 5 cylinder 3 < 300, < 200 |

| 6 air compressor 1 LGFD-2 / 0.9-X |

| 7 various types of pipeline valves |

| 8 kettle pipe insulation |

| Eight Electrical equipment |

| 1 batching control system |

| 2 low voltage control cabinet |

| 3 lighting system |

| 4 each tube cable |

| 5 mating system |

| Payment Terms: | TT/LC |

|---|---|

Member Information

| Jiangsu Baoteng Machinery Industrial Co., Ltd | |

|---|---|

| Country/Region: | Jiang Su - China |

| Business Nature: | Manufacturer |

| Phone: | 13915187087 |

| Contact: | Mr.zhang (Sales Director) |

| Last Online: | 28 Sep, 2017 |

Related Products of this Company

-

Aerated autoclaved concrete bock machine

-

construction machinery or AAC concrete

-

Aerated brick making machinery (annual

-

Aerated brick making machine or AAC

-

Block seperating machine or Aerated

-

building materials production line or

-

construction machinery or AAC concrete

-

Aerated autoclaved concrete block

-

AAC concrete block making machinery or

-

Sand ball mill (wet) of Aerated concrete