| Model: | JY-31803 |

|---|---|

| Brand: | JY |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Stainless Steel |

| Label: | 31803 steel pipe , 31803 steel tube , 2205 steel tube |

| Min. Order: | 1 ton |

| Last Online:11 Sep, 2025 |

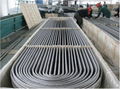

Product Introduction: S31803 (2205) Duplex Stainless Steel Tube

Overview of S31803 Duplex Stainless Steel

S31803, commonly known as 2205, is a dual-phase stainless steel renowned for its remarkable combination of enhanced mechanical properties and excellent corrosion resistance. This material is classified as an ultra-low carbon stainless steel, which makes it particularly suitable for a variety of demanding applications across diverse industries. Its unique microstructure consists of both austenite and ferrite, contributing to its high strength and improved resistance to pitting and crevice corrosion—a significant advantage in environments that are hostile to conventional stainless steels.

Composition and Structure

The chemical composition of S31803 plays a vital role in its performance:

The presence of nitrogen enhances the stability of the austenitic phase, ensuring structural integrity even after exposure to high temperatures and welding processes. This minimizes the risk of undesirable phase transformations that could degrade performance.

Mechanical Properties

S31803 exhibits impressive mechanical properties, making it a reliable choice for critical applications. The key properties include:

These values reflect the material's ability to withstand substantial stress and deformation without failure, which is crucial in many industrial applications.

Applications of S31803 Duplex Stainless Steel Tube

S31803 is widely employed in harsh environments where resistance to corrosion is paramount. Some notable applications include:

Industrial Heat Exchangers: Particularly effective in heat exchangers used in oil and gas industries, where fluids often contain corrosive elements such as H2S, chlorides, and organic acids.

Conveying Pipes: Ideal for transporting fluids in oilfields, oil ports, and wellheads, S31803 tubes ensure reliable performance under varying pressure and temperature conditions.

Air Coolers: Commonly used in air coolers for refineries and hydrogen cracking towers, S31803 provides durability and efficiency in heat exchange processes.

Seawater Desalting Exchangers: The excellent resistance to pitting corrosion makes S31803 an optimal choice for seawater desalination applications, where exposure to saline environments is inevitable.

Petrochemical Industry: This material is well-suited for equipment operating under aggressive chemical processes, ensuring longevity and safety in high-demand environments.

Industry Insights

S31803 duplex stainless steel tubes are increasingly recognized for their cost-effectiveness, especially compared to higher nickel-content alternatives. Their dual-phase structure allows them to provide a favorable balance of strength and ductility, outperforming many standard austenitic and ferritic steels.

The market trend indicates a growing demand for duplex stainless steels due to the rising energy sector’s focus on efficiency and durability. As industries continue to evolve, the need for materials that offer longer usable life and reduced maintenance costs remains critical. S31803 is well-positioned to meet these needs.

Conclusion

In summary, S31803 (2205) duplex stainless steel tubes are an excellent solution for various industrial applications requiring high strength, corrosion resistance, and durability. Their unique properties, combined with a robust chemical composition, make them an indispensable choice for manufacturers and engineers in the oil, gas, and petrochemical industries. As technology advances and environmental conditions become more challenging, the adoption of S31803 is expected to grow, solidifying its role as a critical material in modern engineering applications.