| Model: | BS-SSPT |

|---|---|

| Brand: | BS |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Piping Tubing |

| Label: | 32760 , stainless 32760 , Steel pipe S32760 |

| Price: |

-

|

| Min. Order: | 1 ton |

| Last Online:20 Aug, 2025 |

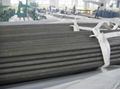

Product Introduction: Super Duplex 100 Alloys

Super Duplex 100 alloys, formally designated as UNS S32760, represent a significant advancement in the metallurgy of corrosion-resistant materials, combining excellent mechanical properties with superior resistance to localized corrosion. These alloys are engineered for demanding applications across various industries, including oil and gas, chemical processing, and marine environments. This product introduction provides a comprehensive overview of the physical properties, chemical composition, and practical applications of Super Duplex 100 alloys in the annealed condition, specifically at temperatures ranging from -20°F to +100°F.

Physical Properties

When assessing the mechanical attributes of Super Duplex 100, key indicators include tensile strength, yield strength, elongation, and hardness. The tensile strength of the alloy is an impressive 109,000 psi (750 MPa), while its yield strength is robust at 80,000 psi (550 MPa). Such characteristics ensure that the Super Duplex 100 maintains its integrity under high-stress conditions. Additionally, the alloy demonstrates a minimum elongation of 25% in 2 inches, indicating its ability to withstand deformation without fracturing, which is crucial in dynamic operational circumstances.

The grain size is another critical factor determining the performance of this alloy. Super Duplex 100 is not only designed to meet stringent grain size requirements but also maintains a maximum hardness of 31 Rockwell C. This combination supports improved toughness and ductility, essential for applications involving high-energy environments.

Thermal properties of the Super Duplex 100 enhance its usability across diverse conditions. With a modulus of elasticity of approximately 31 x 10^6 psi and a mean coefficient of thermal expansion of 7.5 x 10^-6 in/in/°F, this alloy exhibits limited expansion under temperature fluctuations, adding to its dimensional stability. Furthermore, the thermal conductivity is rated at 156 BTU-in/ft²-h-°F, which affirms the alloy's efficient heat transfer capabilities, crucial for industries that rely on thermal management.

Chemical Composition

The performance of Super Duplex 100 is significantly influenced by its chemical composition, which balances critical elements to optimize its resistance to pitting, crevice corrosion, and stress corrosion cracking. The alloy comprises 24.0–26.0% chromium, 6.0–8.0% nickel, and 3.0–4.0% molybdenum, amongst other constituents. This unique combination not only elevates the alloy's corrosion resistance but also enhances its mechanical performance.

Other elements include a maximum carbon content of 0.05%, manganese up to 1.00%, and sulfur and phosphorus at 0.010% and 0.030%, respectively. The inclusion of nitrogen at 0.20–0.30% boosts the strength and resistance to pitting corrosion. Iron makes up the balance of the composition, complemented by copper at 0.50–1.00% and tungsten at 0.50–1.00%. Importantly, the formula’s configuration adheres to the criteria of %Cr + 3.3% Mo + 16% N being a minimum of 40, which is essential for achieving the desired corrosion resistance and mechanical properties.

Applications

Due to its excellent balance of strength, ductility, and corrosion resistance, Super Duplex 100 is extensively used in applications within the oil and gas industry, particularly in subsea projects and offshore platforms that are exposed to harsh marine environments. It is also utilized in the chemical processing sector for piping systems where aggressive chemicals are involved, as well as in heat exchangers and other equipment requiring high resistance to both corrosion and temperature fluctuations.

Moreover, Super Duplex 100's favorable properties make it suitable for fabrication processes such as welding, machining, and forming, allowing for the production of complex components with confidence in material performance.

Conclusion

Super Duplex 100 alloys embody a superior choice for demanding applications necessitating high strength and corrosion resistance. With robust mechanical properties and an innovative chemical composition, these alloys continue to set a benchmark in industries where reliability and durability are paramount. Whether for offshore oil and gas explorations or resilient chemical processing systems, Super Duplex 100 remains a leading material in modern engineering solutions. The enduring performance and adaptability of this alloy ensure its pivotal role in advancing engineering applications worldwide.