| Model: | BS-NAPT |

|---|---|

| Brand: | BS |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Piping Tubing |

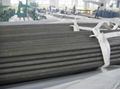

| Label: | Stainless steel tube , stainless steel pipe , Steel pipe |

| Price: |

-

|

| Min. Order: | 1 ton |

| Last Online:09 Mar, 2025 |

Nickel Alloy 22, designated as UNS N06022, stands out as a material of choice for industries that demand exceptional performance under challenging conditions. With its superior tensile and yield strengths, combined with excellent corrosion resistance, Alloy 22 is particularly suited for applications in environments ranging from -20°F to +100°F. This product introduction explores the physical properties of Nickel Alloy 22 in its annealed condition, its composition, and adherence to industry standards, ultimately demonstrating why it is an indispensable material in various sectors.

Physical Properties

Tensile and Yield Strength

Nickel Alloy 22 exhibits impressive physical properties. In its annealed condition, it achieves a tensile strength of approximately 100,000 psi (690 MPa) and a yield strength of around 45,000 psi (310 MPa). These values translate to 100 ksi and 45 ksi respectively, indicating robust resistance to deformation and breakage under stress, which is essential for structural integrity in demanding applications. Additionally, the alloy maintains a minimum elongation of 45% over 2 inches, allowing for deformation without failure, a critical factor in designs where movement or flexing occurs.

Grain Size and Hardness

Nickel Alloy 22 is noted for its fine grain structure, contributing to its enhanced mechanical properties. Although specific grain size requirements are not extensively outlined, the performance characteristics indicate a notable resilience. The hardness of the alloy is typically not quantified to rigid standards, reflecting its inherent ductility and flexibility in forming processes.

Elasticity and Thermal Attributes

The modulus of elasticity of Nickel Alloy 22 is reported at approximately 30.3 x 10^6 psi, indicating its ability to deform elastically when subjected to stress. The mean coefficient of thermal expansion is recorded at 6.7 x 10^-6 in/in/°F, s esting minimal thermal expansion, which is beneficial in maintaining dimensional stability in fluctuating temperatures. Furthermore, its thermal conductivity is rated at 118 BTU-in/ft²-h-°F, ensuring efficient thermal transfer—an essential feature in heat exchanger applications.

Chemical Composition

The unique properties of Nickel Alloy 22 are a result of its carefully calibrated composition:

This combination not only fortifies the mechanical strength of the alloy but also grants it excellent resistance to pitting and stress corrosion cracking, making it suitable for chemical processing environments, oil and gas extraction, and marine applications.

Compliance with Industry Standards

Nickel Alloy 22 conforms to several stringent industry specifications, including B619 and B626. These specifications ensure reliability and traceability in production processes, while also providing benchmarks for quality assurance in production and application.

Applications

Given its exceptional properties, Nickel Alloy 22 finds widespread application across various industries. Some of the primary uses include:

Conclusion

In conclusion, Nickel Alloy 22 represents a pinnacle of innovation in alloy technology, offering outstanding mechanical properties and exceptional corrosion resistance across a broad temperature range. Its adherence to industry standards coupled with its versatile composition makes it a vital material for sectors that cannot compromise on performance. Whether for use in harsh chemical environments or demanding mechanical applications, Alloy 22 stands strong, ensuring reliability and longevity in every project it undertakes. Investing in Nickel Alloy 22 is investing in quality, durability, and peace of mind, affirming its status as a premier choice for professionals worldwide.