| Model: | A |

|---|---|

| Brand: | UPM heat Shrink |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Insulation Material |

| Label: | Identification Sleev , thin wall heat shrin , heat shrink |

| Price: |

US $0.5

/ m

|

| Min. Order: | 200 m |

| Last Online:06 Dec, 2024 |

S2 125 Thin-walled flame-retardant heat shrinkable tube

| Introduction | ||||

| A thin-walled, soft, environmentally friendly, flame-retardant polyolefin heat shrinkable tube, suitable for insulation protection, part number identification, mechanical protection, strapping and fixing of wires, wiring harnesses, and electronic components. | ||||

| Features | |||

| Operating temperature: --40~125 ℃ | |||

| Minimum full shrinkage temperature: 125 ℃ | |||

| Shrink rato: 2:1 & 3:1 | |||

| Environmentally friendly flame retardant,RoHS compliant | |||

| Color: See the color code below for details | |||

| UL224 E341796 compliant | |||

| Technical Data | ||||

| Property | Test Method | Value | ||

| Tensile strength | ASTM D2671 | ≥10.4MPa | ||

| Breakdown elongation | ASTM D2671 | ≥200% | ||

| 2% secant modulus | ASTM D2671 | ≤172MPa | ||

| Aging(158℃/168h)

Tensile strength Breakdown elongation |

ASTM D2671 | ≥7.3MPa ≥100% |

||

| Water absorption (23℃/24h) | ASTM D570 | ≤0.5% | ||

| Low temperature flexibility(-40℃/4h) | ASTM D2671 | No cracks | ||

| Heat shock(250℃/4h) | ASTM D2671 | No drips, no flow, no cracks | ||

| Breakdown voltage | ASTM D2671 | ≥ AC 2500V | ||

| Power frequency withstand voltage | AC2500V,1 minute | No breakdown | ||

| Volume resistivity | ASTM D2671 | ≥1.0×1014Ω·cm | ||

| Flame retardancy (except for transparent) | UL224 | VW-1 | ||

| Copper corrosion(158℃/16h) | ASTM D2671 | No corrosion | ||

| Dimension | ||||

| Size | As supplied(mm) | After shrink (mm) | Standard length | |

| S2 | Diameter | Diameter(Max.) | W T | m |

| Shrink ratio 2:1 | ||||

| 0.6 | 0.9±0.2 | 0.4 | 0.28±0.10 | 200 |

| 0.8 | 1.1±0.2 | 0.5 | 0.28±0.10 | 200 |

| 1.0 | 1.6±0.3 | 0.65 | 0.35±0.10 | 200 |

| 1.5 | 2.1±0.3 | 0.85 | 0.35±0.10 | 200 |

| 2.0 | 2.6±0.4 | 1.0 | 0.40±0.10 | 200 |

| 2.5 | 3.1±0.4 | 1.3 | 0.40±0.10 | 200 |

| 3.0 | 3.6±0.4 | 1.5 | 0.45±0.10 | 200 |

| 3.5 | 4.1±0.4 | 1.8 | 0.45±0.12 | 200 |

| 4.0 | 4.6±0.4 | 2.0 | 0.48±0.12 | 200 |

| 4.5 | 5.1±0.5 | 2.3 | 0.50±0.12 | 100 |

| 5.0 | 5.6±0.5 | 2.5 | 0.52±0.12 | 100 |

| 5.5 | 6.1±0.5 | 2.8 | 0.52±0.12 | 100 |

| 6 | 6.8±0.5 | 3.0 | 0.55±0.12 | 100 |

| 7 | 7.8±0.5 | 3.5 | 0.55±0.12 | 100 |

| 8 | 8.8±0.5 | 4.0 | 0.60±0.12 | 100 |

| 9 | 9.8±0.5 | 4.5 | 0.60±0.12 | 100 |

| 10 | 10.8±0.5 | 5.0 | 0.60±0.12 | 100 |

| 11 | 11.8±0.5 | 5.5 | 0.60±0.12 | 100 |

| 12 | 12.8±0.5 | 6.0 | 0.60±0.12 | 100 |

| 13 | 13.8±0.5 | 6.5 | 0.70±0.12 | 100 |

| 14 | 14.9±0.5 | 7.0 | 0.70±0.12 | 100 |

| 15 | 16.0±0.7 | 7.5 | 0.70±0.12 | 100 |

| 16 | 17.0±0.7 | 8.0 | 0.75±0.15 | 100 |

| 17 | 18.2±0.7 | 8.5 | 0.75±0.15 | 100 |

| 18 | 20.0±0.8 | 9.0 | 0.75±0.15 | 100 |

| 20 | 22.0±1.0 | 10.0 | 0.85±0.15 | 100 |

| 22 | 23.5±1.0 | 11.0 | 0.85±0.15 | 100 |

| 25 | 26.5±1.0 | 12.5 | 0.95±0.18 | 50 |

| 28 | 29.0±1.0 | 14.0 | 0.95±0.18 | 50 |

| 30 | 32.0±1.5 | 15.0 | 1.00±0.20 | 50 |

| 35 | 37.0±1.5 | 17.5 | 1.00±0.20 | 50 |

| 40 | 42.0±2.0 | 20.0 | 1.05±0.20 | 50 |

| 45 | 47.0±2.0 | 22.5 | 1.05±0.20 | 25 |

| 50 | ≥50 | 25 | 1.05±0.20 | 25 |

| 60 | ≥60 | 30 | 1.10±0.20 | 25 |

| 70 | ≥70 | 35 | 1.20±0.20 | 25 |

| 80 | ≥80 | 40 | 1.30±0.20 | 25 |

| 90 | ≥90 | 45 | 1.30±0.20 | 25 |

| 100 | ≥100 | 50 | 1.30±0.30 | 25 |

| 120 | ≥120 | 60 | 1.40±0.30 | 25 |

| 150 | ≥150 | 75 | 1.40±0.30 | 25 |

| 180 | ≥180 | 90 | 1.60±0.30 | 25 |

| Shrink ratio 3:1 | ||||

| 1.5/0.5 | 2.2±0.4 | 0.5 | 0.45±0.12 | 200 |

| 3/1 | 3.8±0.4 | 1.0 | 0.55±0.12 | 200 |

| 4.5/1.5 | 5.2±0.5 | 1.5 | 0.60±0.12 | 100 |

| 6/2 | 6.6±0.5 | 2.0 | 0.65±0.12 | 100 |

| 9/3 | 9.7±0.5 | 3.0 | 0.80±0.15 | 50 |

| 12/4 | 13.2±0.8 | 4.0 | 0.85±0.15 | 50 |

| 15/5 | 16.0±0.8 | 5.0 | 0.90±0.15 | 50 |

| 18/6 | 19.5±0.8 | 6.0 | 1.00±0.20 | 50 |

| 24/8 | 26.5±1.0 | 8.0 | 1.20±0.20 | 25 |

| 30/10 | 32.0±1.5 | 10.0 | 1.20±0.20 | 25 |

| 39/13 | 41.0±1.5 | 13.0 | 1.50±0.30 | 25 |

| 50/16 | ≥50 | 17 | 1.65±0.30 | 20 |

| 60/20 | ≥60 | 20 | 1.75±0.30 | 20 |

| 70/23 | ≥70 | 23 | 1.75±0.30 | 20 |

| 80/26 | ≥80 | 26 | 1.85±0.30 | 20 |

| 90/30 | ≥90 | 30 | 2.15±0.30 | 20 |

| 100/33 | ≥100 | 33 | 2.35±0.30 | 20 |

| Ordering instructions: Please order according to "model-specification-color", such as S2-9/3-0 | ||||

| Color code: black (-0), brown (-1), red (-2), orange (-3), yellow (-4), green (-5), blue (-6), purple (-7) , Gray (-8), white (-9), pink (-P), brown (-T), transparent (-X), yellow-green (-45) | ||||

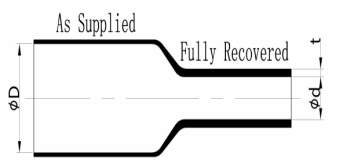

Product diagram