| Model: | SJSZ80/156 |

|---|---|

| Brand: | Qingdao Leader Machinery |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | PVC sheet machine , plastic machine , sheet making machine |

| Price: |

US $60000

/ set

|

| Min. Order: | 1 set |

| Last Online:04 Aug, 2015 |

Plastic machine,Plastic sheet machine,PVC sheet machine, PVC sheet extrusion line

PART1 Specifications of this PVC sheet extrusion line:

Advantages:

1.Uniformed and Even Plasticization

2. PLC Controlled, High Precision

3.CE, ISO, GOST, SGS Certification

4.Life Long Service

THIS EXTRUSION LINE CONSISTS OF :

Sheet thickness: 0.2-2mm sheet width:500-1500mm

Sheet application: PVC sheet for sandwich panel, and PVC edge band for furniture edge banding and skinning, thermoforming packing and so on

jingnianji at hotmail dot com; michael23 dot jing at gmail dot com

PART 2 FEATURES O THIS LINE :

1.Extruder: Special screw structure, imported world-known thermocontrollers, electronics, hard gear face reducers to ensure high effective material extrusion capacity.

2.T -type die head: suitable compression ratio to ensure uniform flow stability.

3.Three-roller calendar: According to the material properties, adopting vertical three-roller, oblique three-roller, horizontal three-roller calendar. Internal roller temperature control using a unique flow channel, so that the stability of uniform distribution roller. The independent oil temperature control for three roller to ensure more stable and exact control.

4.Cooling frame: According to product specifications, configurations with different specifications of the stainless steel cooling roller

5.Edge-cutting devices: Trimming can be divided into manual and automatic, three-dimensional configuration tool adjustment device, width adjustable.

6. Cut off machine: Saw cutting or knife cutting, thin type and non-friable type sheet generally usually knife cut, adopted high-quality alloy cutting tools, sharp and durable.

PART 3 Pictures and technical Parameters

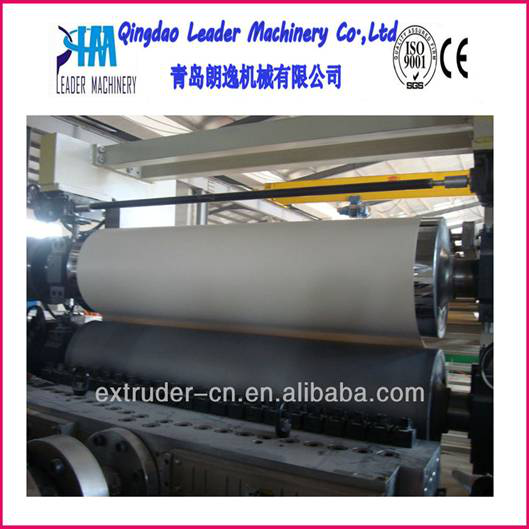

The Whole Line

Spring feeding machine ( charger ) type SJF-700

|

Item |

Description |

Unit |

ZJF-700 |

|

1 |

Feeding Capacity |

Kg/h |

Max.1000 |

|

2 |

Container Volume |

Kg |

150 |

|

3 |

Spring Diameter |

mm |

φ59 |

|

4 |

Feeding Tube and Spring Length |

mm |

3-5 |

|

5 |

Material Trunk Volume |

Kg |

200 |

|

6 |

Electric Power |

|

3-380V 50Hz |

|

7 |

Main Motor Power |

Kw |

2.75 |

|

8 |

Dimensions |

mm |

950×950×960 Φ820×1550 |

|

9 |

Total Weight |

Kg |

250 |

Double-Screw Extruder type SJSZ80/156

T -die head, 1 set

|

Item |

Description |

Unit |

1750mm |

|

1 |

Die width |

mm |

1750 |

|

2 |

Adjusted thickness |

mm |

0.1-1mm |

Three roller calendar

|

|

Discription |

Unit |

|

|

1 |

Roller motor power |

KW |

3*3 sets |

|

2 |

Speed adjusting inverter |

|

ABB frequency inverter |

|

2 |

Roller width |

mm |

1600 |

|

3 |

Roller |

mm |

355 |

|

5 |

Chromed thickness |

mm |

0,05-0,06 |

|

6 |

Roller wall thickness |

mm |

about 35 |

|

7 |

Roller adjusting |

|

Electrical, manual |

|

8 |

Thermocontrol |

|

Mould thermocontroller, 1 set |

Cooling frame, Edge cutting unit, Hauling-off Machine

Knife cutting machine

|

Item |

Description |

Unit |

|

|

1 |

Method |

|

Knife cutting |

|

2 |

Cutting width |

mm |

1600 |

|

3 |

Cutting thickness |

mm |

0.1-1 |

|

4 |

Driving method |

|

Hydraulic |

|

5 |

Length counter |

|

Digital |

Stacker

|

Item |

Description |

Unit |

|

|

1 |

Material of working table |

|

Stainless steel |

|

2 |

Working length |

mm |

3000 |