| Model: | LMSB |

|---|---|

| Brand: | Qingdao Leader Machinery |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | Plastic machine , PP sheet machine , EVA sheet machine |

| Price: |

US $80000

/ set

|

| Min. Order: | 1 set |

| Last Online:04 Aug, 2015 |

PP foam sheet extrusion line,PP PE EVA sheet machine

|

This Line Consists of |

||

|

1. |

Single Screw Extruder |

1 set |

|

2. |

Co-extruder |

Optional |

|

3. |

Extrusion Die Head T-die Head |

JC-Times 1 set |

|

4 |

Hydraulic filter exchanging unit, |

1 set |

|

5 |

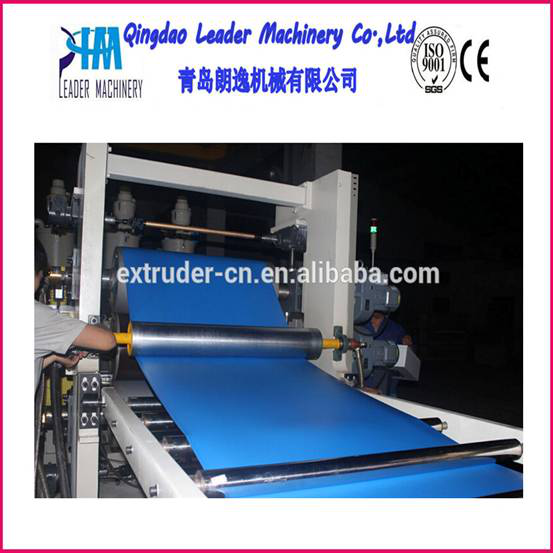

Three Roller Calendar |

1 set |

|

6 |

Cooling Frame |

1 set |

|

7 |

Edge Trimming Unit |

1 set |

|

8 |

Edge Material Crushing Unit |

1 set |

|

9 |

Double Roller Hauling off Machine |

1 set |

|

10 |

Cutting off Machine |

1 set |

|

11 |

Double Station Winding Machine |

1 set |

jingnianji at hotmail dot com; michael23 dot jing at gmail dot com

PART 1: Application:

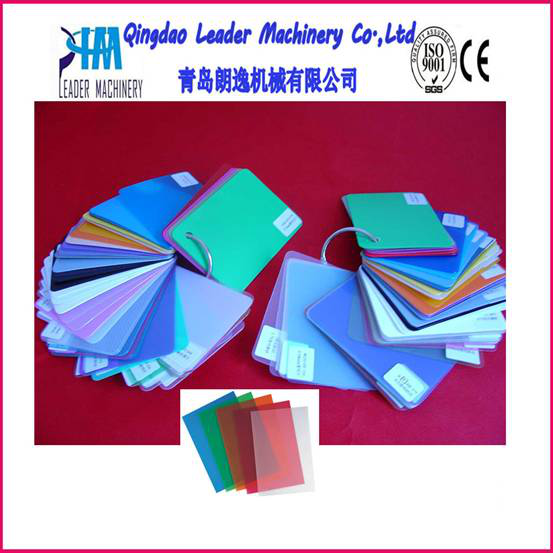

PP PE HIPS PET EVA EVAOH Composite sheet:

It has such characteristics as high intensity, good temperature resistance, good rot proof, etc. It can be produced with additives to different requirement such as improving intensity, improving toughness, improving rigidity, flame retardant, embossing, frosting, etc.

Applications: such as packing, printing, stationary, art works, etc.

Main product:gift/ad/file bag, lamp cover, food packing, etc

PART 2: Sheet Specification:

Usual Sheet Width:600-1800mm

Usual Sheet Thickness:0.2-2mm

Part3 Main technical data and pictures

Single Screw Extruder and T-type Die Head 1 set

|

Item |

Description |

Data |

|

1 |

Mould Materials |

special mould steel 5CrNiMO |

|

2 |

Surface Treatment |

Chromed |

|

3 |

Mouth Width |

900mm |

|

5 |

Brand |

JINGCHENG(JC-TIMES), China |

|

6 |

Heating Method |

Heating Sticks Inside T-die |

|

7 |

Connector Material |

40Cr |

Three-roller Calendar 1 set

|

Item |

Description |

Data |

|

1 |

Roller Motor Power |

1.1 kw*3 |

|

2 |

Speed Adjusting Inverter |

ABB Frequency Inverter |

|

3 |

Roller Width |

950mm |

|

4 |

Roller Diameter |

φ350 mm |

|

5 |

Chromed Thickness |

>0.05 mm |

|

6 |

Roller Wall Thickness |

30 mm |

|

7 |

Roller Adjusting |

Electrical & Manual |

|

8 |

Thermo Control |

Roller Thermo Controller |

Cooling Frame

Edge trimming unit Haul-off Machine and cutting machine

Samples

PART 4: main featurees:

1.Special designed high plasticization high efficiency screw, head finishing reduction gearboxes and high quality converter motors make high output capacity extruder;

2.Well known brand electrical components, high torque force motors, advanced energy saving design lowered energy consumption mostly;

3.High precise T-type die-head, independent oil temperature control high accuracy 3-roller calender, uniform speed and high

traction force haul-off machine with clamp force adjustable rollers make uniform thickness sheet plate production;

4.Whole line with high degree of automation, saving labour resources;

5.Advanced design concept, high quality steel material used in line, strict producing process make high quality lines and can using longer.

Our Services

1. Warranty for machinery: 18months for mechanical parts, 12 months for electrical parts.-Long Time warranty

2. Technical service and support will be forever.-Best service

3. We will dispatch four 1-2 engineers from the seller to the buyer’s factory for installation and commissioning and training till the buyer’s workers can operate the machines independently.- On-site service

FAQ

Welcome your inquiry. Please contact with me freely. I am sure you will get quick and Warmly response.

1. Please kindly inform me specification of the products you want to produce:

If you want plastic pipe, plz Inform us pipe diameter & thickness (SDR)

If you want plastic sheet, plz inform us sheet width & thickness.

If you want plastic profile, plz send us general size, picture or drawings.

2. We will send you the quotation details according to your requirements.