| Model: | SG600 |

|---|---|

| Brand: | Yuanhang |

| Origin: | Made In China |

| Category: | Construction & Decoration / Brick & Tile / Bricks Tiles |

| Label: | Roll Crusher , Double Roll Crusher , Durable Roll Crusher |

| Price: |

US $3000

/ set

|

| Min. Order: | 1 set |

| Last Online:01 Aug, 2015 |

Durable Double Roller Crusher Price for Sale

Laboratory Roll Crushefor Brick Plant Project

| Packaging Details: | Plywood Case or Standard Export Container |

|---|---|

| Delivery Detail: | Within 25 days after prepayment |

Introduction

Roll crusher is generally used as small crushing machine which can be used for crushing materials with medium hardness such as coal, building material and wear-resistant materials, and it has excellent crushing effect on building material and coal. This machine also can be called double roll crusher or teeth roll crusher.

Product Superiority

1) Economic, durable

2) Big crushing ratio

3) Low noise ,high capacity

4) Stable operation, ISO9001

Specifications

1.Used to break medium and small pieces of clay , shale , coal gangue and other raw material .

2.The distance can be adjusted according to the request .

3.The coarse crushing roller has compression spring which can avoid large & hard material coming into the equipment to damage it .

4.Roller is economic , durable and repairable . Working life is long .

5.Flexible installation , low noise, high efficiency

6.Roller’s surface adopt anti-abrasive welding . Self-protection ability is strong

7.48-year credibility & quality assurance

Technical Parameter

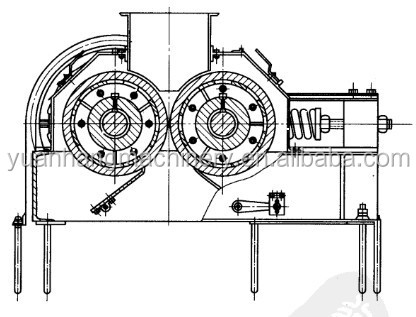

Working Principle

This equipment adopts two motors, which take two rollers to rotate reversely by the decelerator. when the materials drop on the rollers through the charge hole,Under the friction of the rollers, they are dragged between the two rollers, grinded by the roller's crushing, the grinded materials are pushed rotatorily by the rollers.

Pictures of Products

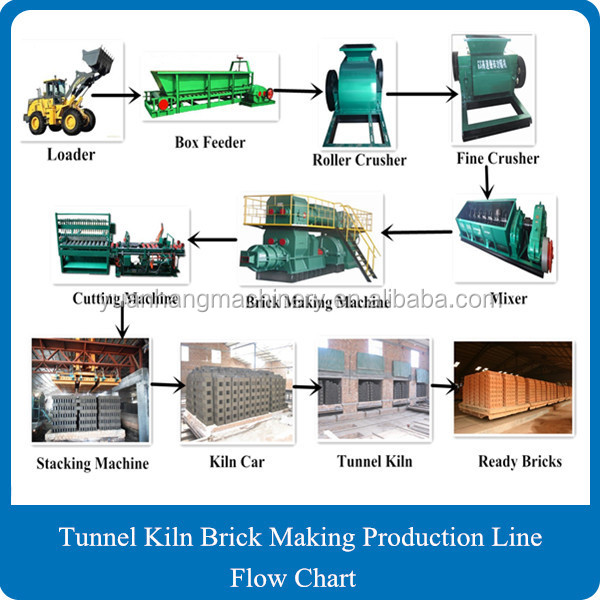

Flow Chart

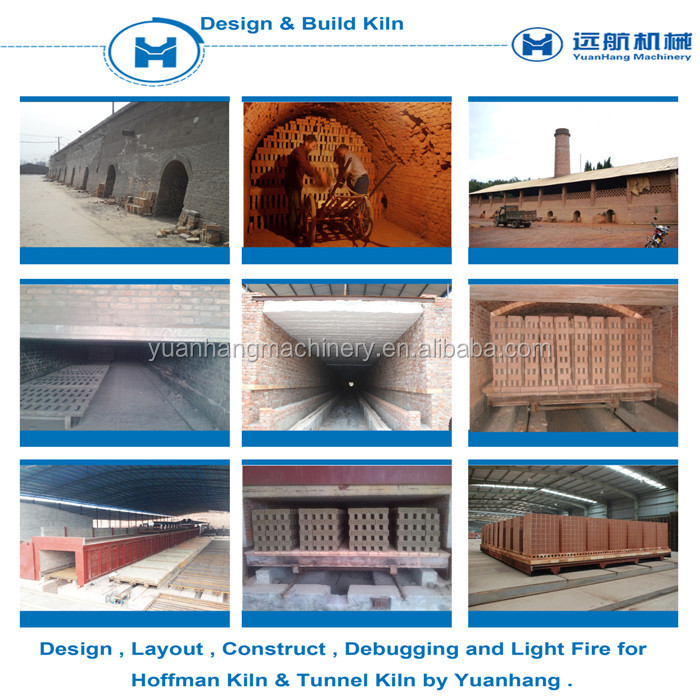

Our company provide the brick factory site design, tunnel kiln construction and a full set of machinery and equipment.

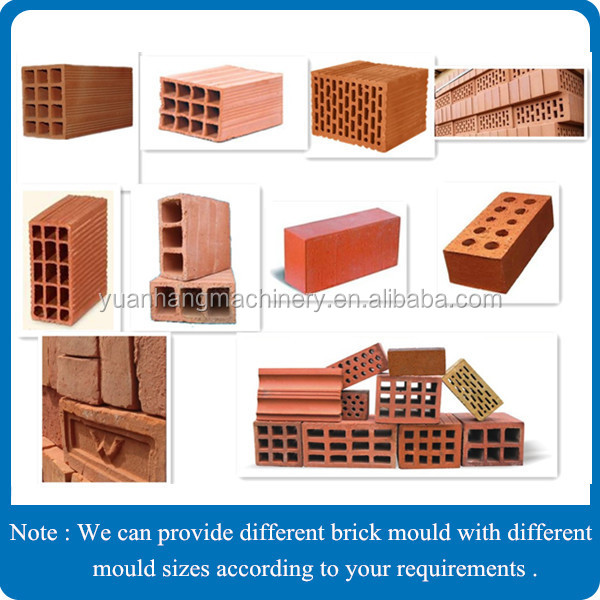

Brick Samples

Company Profile

Company Profile

Yuanhang Group Machinery World Quality

Yuanhang Group Machinery Equipment Co.,Ltd is the high-tech enterprise, integrating R&D, manufacture and trade as one body for clay brick making production line machinery and hoffman kiln and tunnel kiln construction , concrete block making production line machinery and mining machinery with our own brand . The group has 380 workers including 65 medium engineers and 31 senior engineers . The equipment is superior handling , advanced technology and reliable quality .

We provide raw material analysis, site planning, kiln construction , equipment installation and trial running services. We have a professional technicians and engineers teams to support your project . After years of hard exploration, we have established a set of complete and effective service system for before sales , medium sales and after sales .

Our products exported 28 countries and regions , like Indonesia, Myanmar, Kazakhstan, Uzbekistan, Russia, Nepal, Sudan, South Africa, Uganda , Peru , Chile , etc . Our products enjoy a great reputation during the customers and have been sold all over the world .

Welcome you to visit us ! Let’s walk hand in hand , and win the world together .

Service Policy of Roll Crusher

Before Sales:

1> Accept customer consultation. According to the customer request and condition, choose most suitable plan in order to save the customer’s cost .

2> Help and support the customer about the kiln and machinery’s technology.

3> Design and map out the brick plant drawing for ref .

4> Provide relevant technical documents.

5> Take customer to see the machine operation at our site.

Medium-sales:

1> Tracing every step in the production , convey the progress and take photo to the customer .

2> Strictly control the product’s quality in accordance with the contract .

3> Inspect cargo before delivery .

4> Provide the product manual to the customer with the cargo.

5> Make the agenda list to the customer and advise how to operate in proper time .

6> Send engineer and technician to the customer scene , program the site and brick plant map .

After-sales:

1>The engineer and technician investigate the field , climate , raw material , etc. Make the layout and drawing based on this .

2>Provide the construction schedule to ensure the construction will proceed as per the schedule .

3>Guide installation till producing the finished bricks . Meanwhile , we train local workers and mechanic . Answer customer’s questions on site . Guide the buyer to make the maintenance .

4> Guide the customer build hoffman kiln with dryers or tunnel kiln with most advanced technology .

5> Communicate with the customer timely . We have specialized after-sales teams to listen for customer’s feedback. Provide help and support in the whole production line .

Company's Certificate

Please Trust Us:

Contact Us