breakfast cereal cornflakes extruder machine

Product Description

Corn flake is a crisp food, which is one kind of breakfast cereals. Corn flake has the advantages of good rehydration performance, silky mouthfeel and aroma taste. It can be eaten directly, or eaten with water, milk, yoghourt, coffee together. Corn flake adopts corn powder as raw material; sugar, vitamins, mineral as additive. Make flake by adequately extruding, cooking, shaping and drying. The finished production is nourishing, which can replace traditional breakfast cereal food perfectly.

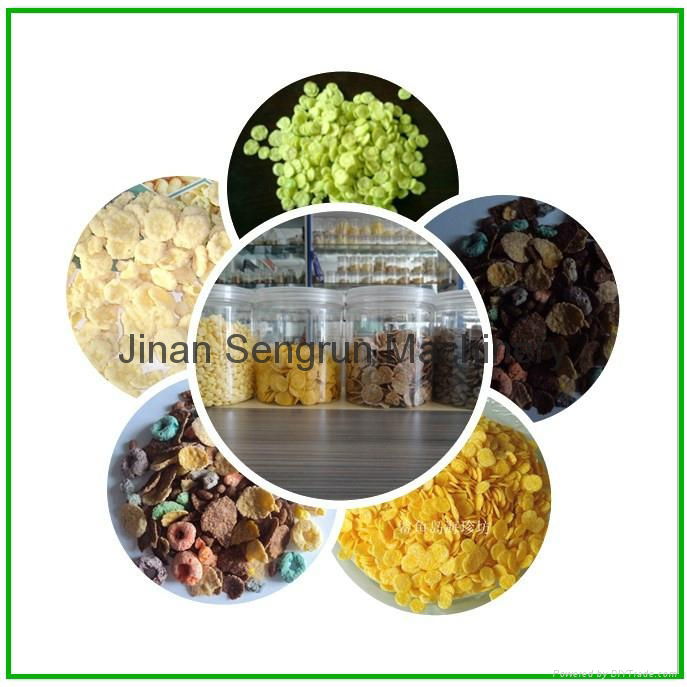

- Corn flake samples introduction

- Raw materials: corn meal, sugar, salt, palm oil, cocoa powder, vitamins, minerals, food color etc.

- Humidity: the moisture is no more than 10%.

- Shapes: round, oval, fingernails. (Change moulds to make all shapes unfilled snack.)

- Sizes: (1) diameter: up to 25mm (2) thickness: user-defined.

- Corn flake processing lines description

- Corn flake processing lines features

- Capacity range is large: our corn flake processing lines capacity range is from 100kg/hr to 350kg/hr.

- Corn flake processing line has wide raw materials application range.

- Our corn flake processing lines’ extruders are twin-screw extruder, there is one couple of screws inside the barrel. The raw material of screws is 38CrMoAl (standard: GB/T 3077-1999). This material’s hardness and strength performance is excellent, which can bear high temperature and high pressure.

- Our twin-screw extruder has self-clean function.

- Our extruders and dryers are equipped with inverters. The inverters are famous brands (Delta, LS, ABB, Siemens etc.).

- Our corn flake processing line automation degree is high, it need only 2-3 workers to operate.

- The production factors can be quantized and controllable.

- We can custom-make all the machineries for corn flake processing line as per users’ requirement. We supply OEM goods.

- All the materials touching food is food grade.

- This line can not only make corn flake, but also make most of expanded snack food.

- Our twin-screw extruders are equipped with forced lubrication system. The driving method can be tape drive or direct-connected.

- Corn flake processing line work flow

- Work flow: Raw material treatment---Extrusion--- Tabletting---Drying---Flavoring---Packing & Detection

- Machineries description in each process

- Machineries in raw material treatment: (1) Grinder or grinding group (option), used for grinding raw materials. (2) Mixer (include propeller type mixer, vertical type mixer), used for mixing all raw materials and adding appropriate water (don’t need to add water into dry powder type mixer), to make the raw materials uniform.

- Machineries in extrusion: (1) Conditioner (option for small capacity lines, necessary for big capacity lines), used for pre-conditioning raw materials. (2) Twin-screw extruder, used for extruding and shaping.

- Machine in tabletting: different models tabletting machines, used for tablleting corn flake from expanded corn ball.

- Machineries in drying: different dryers. Our dryers’ heating power source can be electricity, gas-fired burner (Baltur, Italy), oil-fired burner (Baltur, Italy). It is up to users’ local power situation. Our s estion is electrical dryer, its heating is more balanced.

- Machineries in flavoring: (1) Flavoring hoister, used for hoisting corn flake and adding seasoner. (2) Oil sprayer, used for spraying oil on the surface of corn flake food, make sticking seasoner easier. (3) Single drum, used for mixing corn flake and seasoner (ancillary use with flavoring hoister). (4) Double-drum, used for adding seasoner, and mixing it with corn flake.

- Machineries in packing & detection (option): (1) Cup type packing machine, used for packing corn flake with small size bag by heat-seal. (2) Multi-head weigher packing machine, used for packing corn flake with medium size bag by heat-seal. (3) Big size bag packing machine, used for packing big size bags. (4) Weight detector, used for detecting the goods after packing. It can get rid of the finished product with unqualified weight. (5) Metal detector, used for detecting if there is any metal inside the bag and removing the unqualified one. (6) Weight and metal all-in-one detector, used for detecting both weight and metal, and removing the unqualified product.

- The other machineries may be adopted: (1) Transport machineries, they are screw conveyor, air conveyor, cooling conveyor, hoister, Z type bucket elevator, vacuum suction machine and negative pressure suction machine. They are used for conveying raw materials, self-finished product and finished product between the other machineries. (2) Vibrating screen (option), used for screening corn flake and removing dreg. (3) Stock bin (option), used for storing raw materials or finished product.

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,