| Model: | JK-3640M |

|---|---|

| Brand: | JINGKE |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Engraving & Etching Machine |

| Label: | metal cnc router , cnc router 3640 , metal machine |

| Price: |

US $4200

/ pc

|

| Min. Order: | 1 pc |

| Last Online:30 May, 2016 |

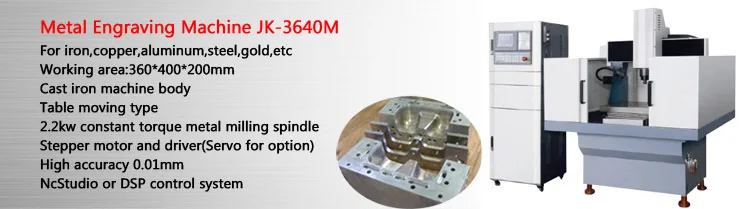

cnc router JK-3640M Jinan jiahe metal engraving machine

JK-3640M Small Metal Engraving Machine adopts new designed structure and high precision linear guide rails and ball screws. This machine can work for engraving letter and designs on iron, copper, aluminum, steel, gold, etc.

Features and Advantages:

1. Wholly cast iron body and table moving to ensure the good accuracy and stability of the machine.

2. X Y Z uses 20mm PMI or HIWIN linear square guide rail. It is more stable and has longer life than normal round one.

3. Z axis use 20mm hign precision ball screw and can avoid spindle suddenly up and down.

4. Break point memory can stop work with wrong signals and avoid the waste of materials.

5. We use high voltage and high torque stepper driver, which is much more powerful than the normal stepper driver.

6. Adopt 2.2KW water cooling spindle, which is suitable for long time and high temperature working.

7. Uses NcStudio or DSP control system, easy and convenient to operate.

8. Many optional configuration and OEM service are available.

Specifications:

| Model | JK-3640M |

| Machine body | Cast iron |

| Working area(XYZ axis) | 360*400*200mm |

| Moving type | Table moving |

| X Y Z rail | PMI/HIWIN linear square guide rail |

| X Y Z transmission | High precision ball screw |

| Spindle | 2.2kw constant torque water cooling spindle |

| Spindle speed | 24000rpm |

| Inverter | 2.2KW inverter |

| Motor | Stepper motor |

| Driver | Stepper driver |

| Transformer | Yes |

| Lubrication | Yes |

| Max. speed | 8m/min |

| Max. working speed | 4m/min |

| Voltage | AC 220V/AC 380V 50HZ |

| Collets | ER20 3.175-12.7mm |

| Repeat reposition accuracy | 0.01mm |

| Cover | X Y Z cover |

| Command | G code |

| Software | Artcam/ Ucancam |

| Control system | NcStudio |

| Remark | Optional driving mode: |

| Servo motor and driver | |

| Optional control system: | |

| DSP |

Samples:

Standard Accessories:

Applicable materials

JK-3640M small metal engraving machine is good at engraving letter and designs on all kinds of metal material, for example, iron, steel, copper, aluminum, gold, etc.

Package

Inner package: stretch film.

Outside Package: Free fumigation wooden case for export.

Shipping

Shipping: by ship from QINGDAO to Your port.

Our Services

1. Technical support online service provided.

2. Technical files service provided.

3. On-site training service provided.

4. Spare parts replacement and repair service provided.

Company Information

We are engaged in research of CNC system and manufacture and sales of CNC routers, including woodworking cnc router, stone cnc router, metal engraving machine, laser engraving machine, etc. Professional design scheme makes perfect combination between performance, precision and appearance. View More>>

What do we supply:

W series cnc router mainly for wood, plastic, acrylic, double-color board etc non-metal materials cutting or engraving.

WL series cnc router mainly for larger wood, plastic,acrylic, double-color board etc non-metal materials engraving or cutting.

S series cnc router mainly for stone, marble, granite etc engraving. 2D or 3D relief.

M series cnc router mainly for metal, like copper, steel, aluminum, silver, gold, stainless steel,ect metal materials engraving letters, relief, mould ect.

ML serials cnc roouter is multi-head cnc router.

ATC series cnc router is with Auto tool changer.

C series cnc router mainly for cylinder materials carving.

Certifications

CE Certificate & ISO9001 Certificate are available.

What do we do for customers?

Firstly, it is better for you to tell us your budget, your carving demand details as following:

1. What is your materials' name.

2. What is your materials' size or dimension.

3. What do you want to do with your materials.

Secondly, it is better to send us your materials(if your material is special) or we will make an effort to look for materials same as yours. Then we do a sample and test for you. Pictures and videos taken for your reference after that.

Thirdly, our team will supply best professional solutions, then quote you with suitable configurations and resonable price. Machine color is up to you!

How it works?

1. Design on the computer by Artcam or Mastercam with art.

2. Output the G-code files.

3. Input the G-code files to DSP system.

4. Put the materials on the table and then run the vacuum pump.

5. Move XYZ back to reference point or mechanical point step by step. Z. X Y axis step by step.

6. Set the working origin

7. Start the control system.

welcome send us inquiry!