Quadrupolar Fiber Coil Winding Station

Product Description

Description:

A comprehensive fully automatic winding station is required to precisely wind optical fiber to manufacture IFOG coils for tactical & strategic grades .In order to improve this working yield, ACWS-230D is developed which winding machine and unwinding machine is separate. The machine is for making coil outer diameter ≤200mm and fiber coating diameter ≤0.5mm, and the total fiber winding length is ≤5km. The fiber coil is winding by the method of QUADRUPOLAR PATTER or continuously straight winding fiber coil .

please contact sales@oelabs.com for more information.

Features:

- The machine enable product spool automatically winding and displacement. Both ends of fiber can be swapped freely.

- Custom-made winding process, including fiber coater diameter, master spool winding slot width and product spool slot width and required tension and etc.

- Fiber coating diameter programmable precision: 0.001mm

- Master spool winding slot width and product spool slot width programmable precision: 0.001mm

- Splitting axis precision: 0.01mm

- Splitting axis repeatability position precision: 0.003mm

- Adjust fiber tension level within resolution of ±2g ; rather stable in the support of closed-loop tension controller.

- Fiber total length programmable precision: 0.1m ( resolution of ± 0.3%)

- While in winding, the fiber on master spool will be discharged automatically

- 2 unwinding functions available , one is stopping to unwinding during winding of the fiber ; the other is to unwinding for the whole layer

- Automatically collecting this fiber during un-winding the fiber

- Locate this zero-point for this main axis and splitting axis

- Optional: Vision system are built for inspecting this whole winding process

(Just for inspecting, not for controlling the progress connected with winding machine)

|

Option Introductions:

|

|

1. Industrial vision system and illumination device

In order to keep the coil winding well,it should be equipped with industrial vision system with fivevisual adjustable device and assistant illumination device which operation is by manually. It adopted the remote switches controlling for the assistant illumination device.

The CCD system can be amplified 20-100times, it facilitate the fiber winding inspecting clearly

and easily. It substantially save the manpower and improved the quality .

2 Dynamic Length Meter

This device is built-onto the winding machine, it can write the length of the coiled fiber for current layer of the winding bobbin . Its precision can reach ±0.3%; it's very convenient to record the actual length of the coiled fiber .

3. Epoxy Delivery System

In order to make a good fiber coil, there are two installations for epoxy delivery with temperature controller onto the right or left displacement, which is adjusted by manual.

The epoxy delivery system is built-into heating device and temperature controller, which is to heat the glue and keep it at the exact working temperature. Also it can it can reduce the viscosity of colloid .and to glue symmetrically.

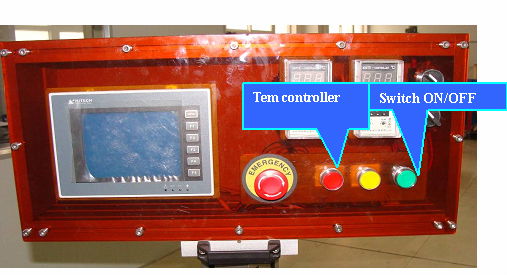

There are two switches and temperature-controller for controlling epoxy delivery onto the main controlling panel. The heater and motor can work when the switch is on, when the switch is off, its heater and motor can be cutting off.

4. Ultraviolet Solidify Lamp

In order to make this winding well, there is a UV lamp built-into two dimensions stages onto the top of winding machine, which is adjusted by manual. The UV lamp can be activated via remote-control.

5.Ultraviolet Protective Cover

In order to avoid hurting the workers when operating the Ultraviolet solidify lamp, put down the window shade and cover the gluing device with ultraviolet cover before turning on the Ultraviolet solidify lamp, then turn on the ultraviolet solidify lamp with remote control switch and timing, Turn off the ultraviolet lamp after timing then do other operation.

We can make other optional accessories on request. It is welcomed that you tell us your detailed Requirements.

|

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,