| Model: | 1.3343/M2 HSS |

|---|---|

| Brand: | DIN 1.3343 / AISI M2 High Speed Steel |

| Origin: | Made In China |

| Category: | Metallurgy , Mining & Energy / Metallurgy & Mining / Bars, Rods, Angles, and Stainless Steel Shapes |

| Label: | M2 high speed steel , 1.3343 HSS , 1.3343 tool steel |

| Price: |

-

|

| Min. Order: | - |

| Last Online:05 Jul, 2016 |

1.3343 Tool Steel

|

Standards |

DIN |

AISI |

JIS |

ГОСТ |

|

HS6-5-2 |

1.3343 |

M2 |

SKH51 |

P6M5 |

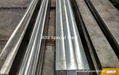

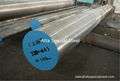

ALTA SPECIAL STEEL supply DIN 1.3343 / AISI M2 in round bar and plate.

As a tungsten molybdenum high speed steel, it widely used in the production of machine tool bits,cold forming tools and cutting tools. 1.3343 high speed steel offers high toughness combined with good cutting powers and will withstand increases in temperature without losing its temper.

We welcome your inquiries for tool steel, please contact us for quotation sales@altaspecialsteel.com

_________________________________________________________________________________________

Chemical Composition

|

C |

Si |

Mn |

P |

S |

Cr |

Mo |

V |

W |

|

0.86-0.94 |

≤0.45 |

≤0.40 |

≤0.030 |

≤0.030 |

3.80-4.50 |

4.70-5.20 |

1.70-2.10 |

5.90-6.70 |

Product Range

Round bars : Dia 80mm - 200mm

Flat bars : Thick 45mm - 100mm, width up to 610mm

_________________________________________________________________________________________

Applications : tools for cold work and for considerably stressed tools for cutting of material with the middle and higher firmness such as tools requiring especially good toughness, efficient milling cutters, drills, taps, reamers, saws of all kinds, cutters for gearing, screw dies, brooches, inserts for circular saw blades, slotting tools and wood working tools. The steel is appropriate for coating, nitride of titanium. Bimetal bandsaw blades, Tool bits,High speed steel tool bits, slitting cutters, slitting spacers.

_________________________________________________________________________________________

Heat Treatment

|

Way |

Temperature[℃] |

Remark |

|

Forging |

900 - 1100 |

|

|

Soft annealing |

770 - 820 |

Max. 269HB after annealing |

|

Quenching |

1190 - 1250 |

Cool in in hot bath at 550℃ or air |

|

Tempering |

550 - 570 |

|

|

℃ |

500 |

550 |

600 |

650 |

|

HRC |

64 |

65 |

64 |

61 |