Hot selling 50TPD edible oil refining plant

Product Description

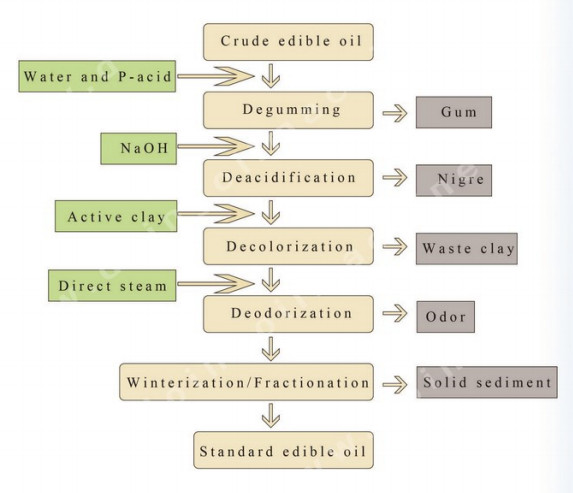

Process of 50TPD edible oil refining plant comprises following sections:

- Neutralizing / Degumming

- Bleaching Section

- Deodorizing Section

Bleaching Section

- In the bleaching section, high vacuum is created in which the neutralized washed oil is pumped into the bleacher vessel for remove excess color from oil

- Firstly, the oil is heated for complete removal of excess moisture and post that, it is treated with measured quantity of bleaching earth & activated carbon

- Later on, the oil passes through a filter media (pressure leaf / filter press) for the separation of spent bleach earth and bleached oil

- From bleaching section, the oil obtained is clear golden in color

Dewaxing And Winterisation (Fractionation)

- With this Dewaxing and Winterization (Fractionation), the oil produced is clear and brilliantly refined oil and to meet certain specifications of cloud point.

- As compared to other oil, sunflower and rice bran oil contain waxes and hence, specially subjected to de-waxing process called Winterization Plant. Through this process, the oil is get separated from waxes thus producing sparkling good quality edible oils.

- For the complete removal of wax from oil, firstly, the oil is first processed in crystallizer where cooling is done by chilled water circulation. In this process, crystals are formed from the wax and after this, it is passed through the filtration process. Post wax separation, the de-waxed oil is collected.

- For uniform cooling and effective nuclei growth of particle, the crystallizer designed geometrically.

Deodorizing Section

- This process ensures the improved quality of oil with its enhanced shelf life

- Directly charged to deodorizer or through heat exchanger, the bleached oil is heated under high temperature and high vacuum to obtain odorless clear oil

- Post processing, the extracted oil obtained is odorless and light in color

- In order to obtain sparkling light color and odorless oil for packing, post cooling, the oil is passed through polishing filter

Dry Fractionation

- Our expertise lies in providing low operating cost fractionation plant that is designed for producing high olien and soft stearin yields. This plant is PLC programmed for efficient working and reliability.

- In rotary vacuum drum filter, the continuous separation of stearin and olien is carried out. In comparison to this process, crystallization process works on the perfect principle of developing and growing particles size for easy smooth separation of Stearin and Olien.

Hydrogenation

- Also known as fat modification, Hydrogenation involves a unique 3 phase process system comprising of solid (nickel catalyst), liquid (oil) and gas (hydrogen). Further a selective reaction, by bringing gas-hydrogen, liquid-oil to the solid-Ni Catalyst and this technological concept formalized an Engineering Design. We offer hydrogenation / fat modification plant, which have several benefits.

The experience and specialization of Doing:

A.40 years manufacturing experience.

B. 26 technical engineers research new efficient processing craft and instruct manufacturing and installation.

C. 76 technicians - professional installation team -with rich and mature installation and training experience.

Henan Doing Mechanical Equipment Co.,ltd

Contact: Ms Sophia

Skype: sophia.zang1

Whatsapp: 0086 135 2662 7860

Phone: +86 135 2662 7860

Tel: +86 371 5677 1823

Email: oilmachine@doingoilmachine.com

Website:www.doinggroup.com

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,