Digital Ring Die Countersink NC Control Machine for Pellet DJ370

Product Description

Key specifications/special features:

Digital ring die-chamfering countersink machine MLT-DJ550

This machine is used on pine wood pellet, straw pellet ring die and bigger hole product

Equipment features:

- High-automation, easy hole-machining operation

- Low consumption of electricity

- Low production cost (one labor can run over 10 such drilling machines)

- If the depth of the pressure-relief vent at both ends of the ring-die are different, the depth can be set in this system in advance then this drilling machine can operate to this depth automatically

- Number of holes can be set at random but holes will evenly distribute on the circle of the ring dies surface

- Those holes on the odd row and the even row will automatically mismatch

- Wear detection on main-axis torque and alarm limitation can be set at will, the wear on drill head can be monitored at any time thus it can effectively prevent drill-head breaking unexpectedly

- During drilling machine operates, the falling speed/rotate speed of drill chuck and indexing speed of universal indexing head can be adjusted at will

- Falling depth of drill chuck can be set at will, the semi-finished holes can be conveniently improved by hand

- With the alarm detection function, the machine greatly shortens invalid operation time when the drill-head is broken

- Pause/start at any time, unnecessarily point to the hole

- Memory function when power-off

- Holes' number distributed on the circle of ring-die or roller-assembly

Service item:

- Machine warranty period is 12 months once the customer receives the machine

- After 12 months, we may answer the customer's question online or by E-mail within 24 hours

- Mltor will prepare one more set of quick-wear components with the machine for the customer

- Mltor will not provide or change any part or component for free if the customer damages them abnormally

- Customer needs to purchase them separately

- Mltor will afford the customer's technician local transportation, accommodation and catering cost when the customer's technician comes to Mltor factory to have a train or inspects the machine before the machine delivery

- Customer will afford their technician traveling cost

- In the warranty period, if the customer requests Mltor engineer to support in foreign country, Mltor will support to check equipment and train the customer technician for free but the customer needs to afford Mltor's engineer traveling expenses, local transportation, accommodation and catering cost.

| Main configuration-MLT-DJ550 |

| Forward and backward travel range |

560mm |

| Z axis travel range |

330mm |

| Chamfering hole diameter |

1.2-6mm for feed pellet

6-12mm for wooden pellet

|

| The minimum Ring die inner size |

450mm |

| The maximal Ring die outer size |

1500mm |

| Ring die thickness |

≤550mm |

| Positional accuracy |

0.02mm |

| Speed of main shaft |

0-3000rpm for feed pellet

0-1500rpm for wooden pellet

|

| Main shaft power |

2.2kW |

| Power requirement |

415V, 50Hz |

| Main components |

| Lead screw with precision grade |

Taiwan brand, 2 pieces |

| Linear guide rail with precision grade |

Taiwan brand, 4 pieces |

| Mltor control system |

including 3 sets of servo drive and motor |

| Electric cabinet |

Schneider component |

| Hand wheel controller |

Convenient for drilling control |

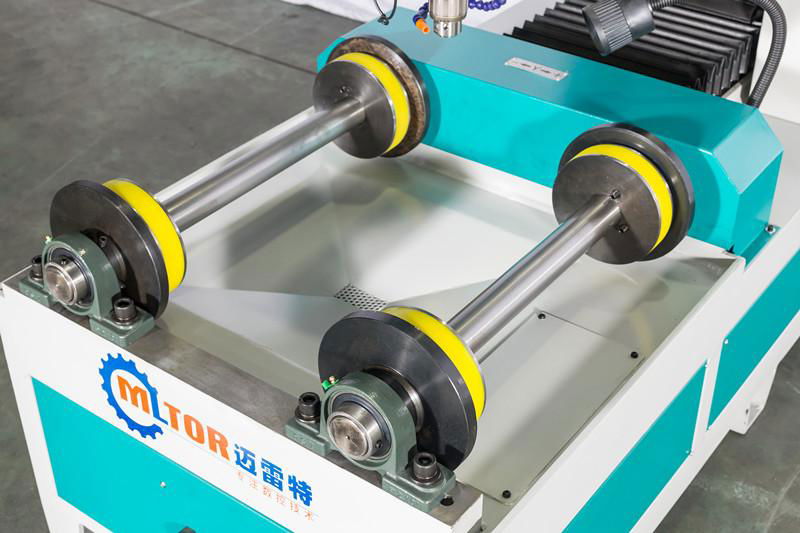

| Ring die driving roller |

2 pieces of heat treatment |

| Cooling tank |

Water pump and a lubrication pump |

| Spare parts along with delivery |

| Proximity switch |

1 piece |

| Magnet |

1 piece |

| Anchor screw-M16*40 |

4 pieces |

| Hex key-1.5-10 |

1 piece |

| Rubber wheel |

2 pieces |

Product Image

Img 1

Img 2

Img 3

Img 4

Img 5

Send Inquiry to this Member

Related Products of this Company

This member assumes full responsibility for the content of this listing. DIYTrade accepts no responsibility whatsoever in respect of such content.

To report fraudulent or illegal content, please

click here.

China Suppliers Quick Searching:

,