| Model: | - |

|---|---|

| Brand: | ZHONGTUO |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | steel roof battens , roof battens machine |

| Price: |

US $13000

/ SET

|

| Min. Order: | 1 SET |

| Last Online:20 Mar, 2018 |

Steel Roof Battens are a versatile and easy to use batten, they can be fixed directly to the rafters using timber or metal self drilling screws, or nails through the flanges. The roof cladding is then fixed to the Battens using self drilling screws.

Here is a drawing profile and finished product of the steel roof battens

Advantage of steel roof battens

Long life, quality: Roof Batten section is guaranteed a long life; all material conforms to Australian standards. Steel Roof Battens are impervious to white ants, borers or rotting. TrueCore zinc/ aluminium coated steel provides the best protection from the environment, giving long life to any building.

Labour and cost savings: Roof Batten section is manufactured locally by continuously roll-forming prefinished steel coil, and with the efficient profile it is a low cost building material. Ease of construction and fast fixing of frame members allow fast erection time, and low labour costs. A protective coating on the section means it will last for years without the need for attention, keeping maintenance costs very low.

Flexibility: By using Steel Roof Battens you have complete freedom of design, with alterations, additions and renovations also easily made. Indeed Roof Battens are suitable for applications other than roofing. Steel Roof Battens can be used for framing van bodies, floor stiffeners, bracing, awning support frames, furring channel and shelving.

Compatibility: Steel Roof Battens are compatible with all standard roof cladding materials, and it can also be used in combination with other systems such as timber.

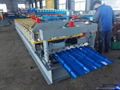

Here is a picture of steel roof battens roll forming machine

Parameters of steel roof battens roll forming machine:

Size: 4800х800х1400

Weight t: 2.2tons

Voltage:380V/50HZ3Phase(as customer's request)

Roller fixer : Guide column

Frame : middle plate welded

Memorial arch frame type

Frame thickness:25mm

Drive mode: gear

Material of rollers: GCr12 ,QUENCING 58-60° dedicated processing

Material of shafts: 45# steel with tempering

Diameter of shafts: φ50mm

Number of rollers :12rollers

Main power: 5.5 kw

Speed: 25 m/min

Cycloidal planetary gear speed reducer