| Model: | - |

|---|---|

| Brand: | - |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | air-conditioning , injection , mould |

| Price: |

-

|

| Min. Order: | 1 pc |

| Last Online:29 Sep, 2020 |

JMT MOULD

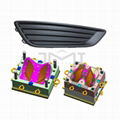

JMT mold has made so many air condition moulds. We can provide air-conditioning shell mold, vertical air-conditioning plastic shell mold, wall-hanging air-conditioning shell injection mold, vertical air-conditioning panel mold, hanging air-conditioning panel mould, full set of vertical air-conditioning plastic accessories mold, full set of air-conditioning plastic accessories mold.

Mold material: P20,718,718H, 2738,2316, S136 and so on, there are a variety of materials for your choice,

Mold base: 45 # pre-har t; 30 HRC

Cooling system: Optimize the design of the circulating water, improve production efficiency and reduce your costs

Medium-term processing: to improve the hardness, by mold quenching and tempering, mold heat treatment, etc.

Post processing: nitriding (By nitriding, the temperature is low, so it can reduce deformation, by this way, the surface of the mold has high hardness (greater than HV850) and wear resistance.

Mold lifetime: the normal life of P20 molds will not less than 500,000 times.

Method of transport: Before the shipment of mold we must will install mold lock on the mold to prevent from the mold move. And the package is hard and antirust. Air or Sea shipment.

After-sales service: Mold warranty 1 year.

Other service: We will provide customers with mold progress and take pictures mold every week.

Our strength of JMT’s air-conditioning injection molds:

a.Their molded product surface are without burrs, the internal non-conductive impurities, the material is enhanced polypropylene.

b.All the technical requirements, the design of the corresponding mold and its main components are based on customer drawings, c.Must set the lateral classification of core pulling mechanism,

d.Must make out the main process of the mold making!

JMT mold try our best to create perfect service for customer, regard customer requirements as a benchmark! Give you the perfect air-conditioning accessories mould.

BASIC INFOMATION

|

Name |

|

|

Plastic resin |

ABS |

|

Mould dimension(mm) |

1700*980*1140 |

|

Mould weight (T) |

14T |

|

Mould cavity steel |

1.2083 |

|

Mould Core steel |

1.2344 |

|

Manufacture time (day) |

65~70DAYS |

|

Mould life |

≥500000 |

|

Cycle time |

120 S |

|

Cooling line connector type |

DME NS350 SERIES quick coupling, excellent cooling system design, cooling design will as many as possible to cooling best |

| Payment Terms: | T/T |

|---|---|