| Model: | OSR |

|---|---|

| Brand: | BLUE |

| Origin: | - |

| Category: | Construction & Decoration / Building Heater |

| Label: | Danfoss , emerson , reservoild |

| Price: |

US $42

/ pc

|

| Min. Order: | 1 pc |

| Last Online:28 Oct, 2021 |

General Description:

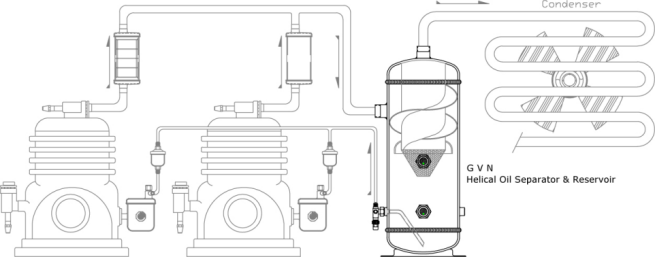

Helical type oil separators with tank can be used in various applications.

Multi-compressor units are among widely used applications

Helical type oil separators with tank are designed for high-pressure oil management systems.

These products are especially designed for scroll and piston type compressors.

Not recommended for screw or rotary compressors.

Standard product series are designed for usage with relevant oils and HFC cooling substances.

Spiral (helix) system and stainless filter system in the product are more effective in separating oil than standard oil separators.

The product provides 99% output in case of selecting model suitable for the system.

Gas/oil mixture is moved along spiral path by centrifugal force, and oil particles revolve on surface of perimeter and collide with layer.

Separated oil is stocked in a tank placed in bottom layer together with directing particles within the system. Flow of oil in desired direction can be ensured using 3/8 rotolock valve on bottom base.

No buoy system is available in the product.

Connection Parts:

We determined Input and Output connections according to volume of products

ODS connection is used in standard products.

3/8” Rotalock Valve is installed at tank output in standard products.

Different connection may be used upon request

We determine models of Sight Glass according to diameter of products.

Sight glasses may be decreased and increased up to desired number.

2 Sight Glasses are available in standard products.

If you want to use different models of Sight Glasses, you may see models on page 58 and order them

We strongly recommend using Liquid Level Sensor with products.

There is oil level sensor connection in standard products

Note:

Our firm manufactures products of any required diameter, length, and properties according to relevant standards.

Different colors may be used upon request in number of quantities.

Oil Separators are manufactured in accordance with CE 97/23/EC directive.

Please, contact us for further details.

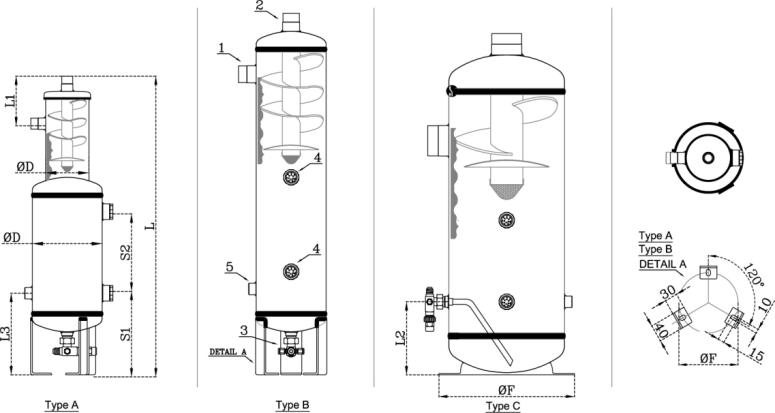

1 - Inlet Connection 2 - Outlet Connection 3 - Oil Return (3/8" SAE Rotalock Valve ) 4 - Sight Glass 5 - Liquid Level Sensor Connection(For Model LLS-01)

| Model | Volume Lt. | Dimensions | Type | Connections | Sight Glass | CEPED 97/23/EC | |||||||

| D | L | L1 | L2 | L3 | F | Type Tip | Sg1 | Sg2 | PED97/23/EC | ||||

| (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | (mm) | 33 Bar | |||||

| BLR/OSR-058 | 3.3 | ∅ 102 | 496 | 93 | 88 | 111 | D | 5/8''ODS | SW36 with Swiming Ball | 88 | 120 | - | |

| BLR/OSR-178 | 6.8 | ∅ 102/165 | 695 | 110 | - | 190 | 140 | A | 7/8" ODS | 190 | 180 | CAT II/A1 | |

| BLR/OSR-1118 | 6.8 | ∅ 102/165 | 695 | 110 | - | 190 | 140 | A | 1 1/8" ODS | 190 | 180 | CAT II/A1 | |

| BLR/OSR-2138 | 13.2 | ∅ 165 | 842 | 142 | - | 200 | 140 | B | 1 3/8" ODS | 230 | 220 | CAT II/A1 | |

| BLR/OSR-2158 | 13.2 | ∅ 165 | 850 | 150 | - | 200 | 140 | B | 1 5/8" ODS | 230 | 220 | CAT II/A1 | |

| BLR/OSR-2218 | 14.2 | ∅ 165 | 855 | 155 | - | 200 | 140 | B | 2 1/8" ODS | 230 | 220 | CAT II/A1 | |

| BLR/OSR-3218 | 21.5 | ∅ 219 | 710 | 205 | 150 | 150 | VFC-247 | C | 2 1/8" ODS | 150 | 150 | CAT II/A1 | |

| BLR/OSR-3258 | 38.3 | ∅ 273 | 800 | 255 | 170 | 170 | VFC-320 | C | 2 5/8" ODS | 170 | 190 | CAT III / B+C1 | |

| BLR/OSR-3318 | 54.7 | ∅ 324 | 820 | 280 | 190 | 190 | VFC-320 | C | 3 1/8" ODS | 190 | 130 | CAT III / B+C1 | |

| TECHNICAL DATA | |

| Working Pressure [PS] | 33Bar |

| Test Pressure [PT] | 48Bar |

| Allowable Temperature [TS] | Min. - 10°C/Max.-130°C |

| Color [RAL] | 5009 |

| General Tolerans [mm] | ±5 |

| Model | Capacity In kW Of Refrigeration At Nominal Evaporator Temperature(KW) | Maximum Discharge Volume(m3/h) | |||||||||||

| R404A / 507 | R22 | R717 | |||||||||||

| "- 40˚ C | 5˚ C | "- 40˚ C | 5˚ C | "- 40˚ C | 5˚ C | ||||||||

| BLR/OSR-178 | 26.8 | 26.8 | 33.4 | 33.4 | 27.1 | 27.1 | 31.0 | 31.0 | N/A | N/A | 12.6 | ||

| BLR/OSR-1118 | 44.4 | 44.4 | 55.3 | 55.3 | 44.9 | 44.9 | 51.3 | 51.3 | N/A | N/A | 20.8 | ||

| BLR/OSR-2138 | 66.3 | 66.3 | 82.6 | 82.6 | 67.0 | 67.0 | 76.6 | 76.6 | N/A | N/A | 31.0 | ||

| BLR/OSR-2158 | 92.6 | 92.6 | 115.3 | 115.3 | 93.6 | 107.0 | 107.0 | 94.03 | 125.38 | 43.3 | |||

| BLR/OSR-2218 | 96.8 | 96.8 | 120.5 | 120.5 | 97.8 | 111.8 | 111.8 | 98.27 | 131.02 | 45.3 | |||

| BLR/OSR-3218 | 205.8 | 205.8 | 236.7 | 236.7 | 208.8 | 219.5 | 219.5 | 214.40 | 257.28 | 74.1 | |||

| BLR/OSR-3258 | 241.6 | 241.6 | 301.0 | 301.0 | 244.3 | 279.2 | 279.2 | N/A | N/A | 113.1 | |||

| BLR/OSR-3318 | 342.4 | 342.4 | 426.6 | 426.6 | 346.2 | 107.0 | 395.7 | N/A | N/A | 160.2 | |||

All data is for a 38˚ C condensing temperature, 18˚ C suction temperature and a connection size the same as the compressor discharge valve.

* Form of using within the system and internal design are clearly shown in table on the side.

Production site: