| Model: | F20-F220 |

|---|---|

| Brand: | Sicheng |

| Origin: | Made In China |

| Category: | Industrial Supplies / Tools / Abrasives |

| Label: | Black SiC , Black SiC Grain |

| Price: |

US $1780

/ MT

|

| Min. Order: | 1 MT |

| Last Online:18 Feb, 2022 |

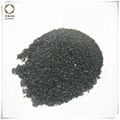

Black SiC Abrasive Grain

Black Silicon carbide is an extremely hard carborundum, it is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke.

Silicon Carbide is produced by a process involving the electrochemical reaction of silica(SiO2) – in the form of quartz mixed with Carbon(C) in the form of raw petroleum coke. The stoichiometric mixture is reacted in an electrical resistance furnace at a temperature of up to 2500℃ to yield high-quality crystals. The process is large furnace technology with a graphite electrode in the furnace center. The large crystals are then segregated, crushed, cleaned of magnetic impurities in high-intensity magnetic separators, and classified into narrow size fractions to suit the end-use. Dedicated lines produce products for different applications.

High hardness, retaining hardness and strength at high temperature.

High wear resistance.

Excellent thermal shock resistance with high thermal conductivity and low linear thermal expansion.

Good ability to withstand the strongest alkalis and acids.

· low density

· low thermal expansion, oxidation resistance

· excellent chemical resistance

· high thermal shock resistance

· high wear and hardness resistance

· high strength, high-temperature resistance

· high-temperature strength

| TYPICAL CHEMICAL ANALYSIS | |

| SiC | ≥98% |

| SiO2 | ≤1% |

| H2O3 | ≤0.5% |

| Fe2O3 | ≤0.3% |

| F.C | ≤0.3% |

| Magnetic content | ≤0.02% |

| TYPICAL PHYSICAL PROPERTIES | |

| Hardness: | Mohs:9.2 |

| Melting Point: | dissociated at about 2300 ℃ |

| Maximum service temperature: | 1900℃ |

| Specific Gravity: | 3.2-3.45 g/cm3 |

| Bulk density(LPD): | 1.2-1.6 g/cm3 |

| Color: | Black |

| Particle shape: | Hexagonal |

| Modulus of Elasticity | 58-65x106 psi |

| Coefficient of Thermal Expansion | 3.9-4.5 x10-6/ ℃ |

| Thermal Conductivity | 71-130 W/MK |

| AVAILABLE SIZES | |

| 8# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 10# 12# 14# 16# 20# 22# 24# 30# 36# 40# 46# 54# 60# 70# 80# 90# 100# 120# 150# 180# 220# | |

Coated abrasive tools such as polishing wheel, sanding paper, flap disc, fiber disc, etc.

Lapping and polishing,

Refractory, Furnace Burden, Casting, Ramming Compound, Refractory Bricks etc

Kiln furniture

Blasting, surface Treatment, Rust Removal

Grinding wheels, sandpaper etc

Raw material of Knife Grinder, Whetstone, oilstone, grinding stone, abrasive stones and so on

Wear resistance parts

Ø We are a manufacturer, which can control the cost easier than trade company also can give you answer more quickly.

Ø As a manufacturer, we know much in technique and can give you more support in technique problem

Ø Professional and experienced service team, specialized in abrasive production , more than 10 years.

Ø Our products are complete in specifications with various of sizes

Ø We enjoy a good reputation in the customers in domestic and overseas markets.

Ø Large production capacity, short lead time of products.

Ø 24*7 online service.

WhatsApp / Mobile: 0086 13526538098