| Model: | Winner 2018 A/B |

|---|---|

| Brand: | Winner |

| Origin: | Made In China |

| Category: | Industrial Supplies / Other Industrial Supplies |

| Label: | particle analyzer |

| Price: |

US $15398

/ pc

|

| Min. Order: | 1 pc |

| Last Online:13 Oct, 2023 |

Product Description

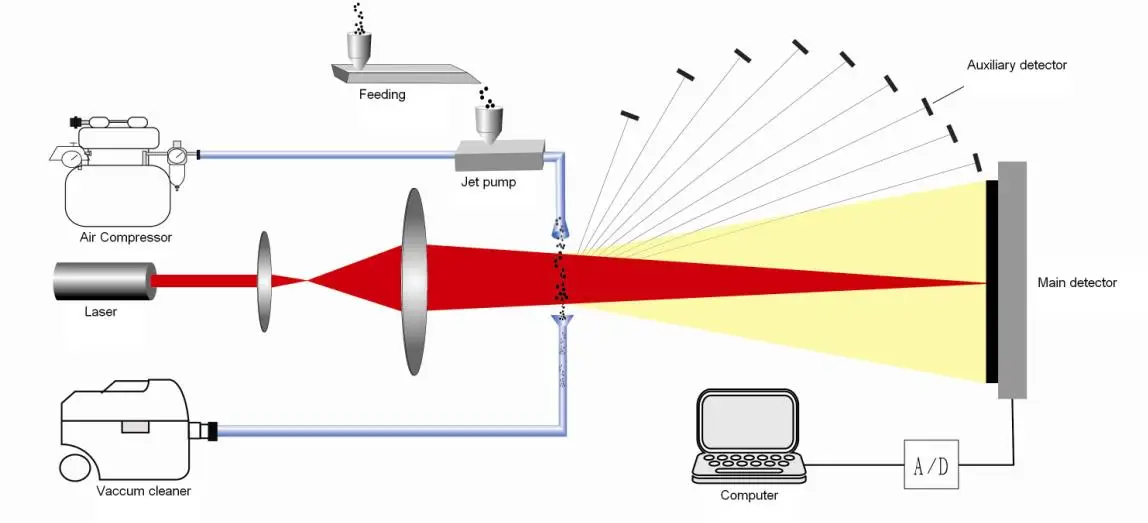

Winner2018 Automatic laser particle size analyzer, perform auto test, auto alignment, auto water supply, auto drainage, auto bubble removing, auto ultrasonic dispersion, auto cleaning etc., really realize one-key operation. It adopt full built-in sampling system, effectively prevents large particles sedimentation problems in the circulation pipeline, ensure good accuracy. It uses comprehensive Laser diffraction particle size measurement principle with highly sensitive ring-shaped photoelectric detector improving the test accuracy greatly, Original designed unconstrained free fitting software technology, a true reflection of the particle size distribution, to ensure truth and accuracy of the test results, its measuring range is 0.1 micron to 450 micron, more suitable for Testing of materials with narrow particle size distribution.

Main Features

1,Unique optical path patent technology, highly improve test resolution.

A patented technique of Fourier transform of converging light released the scattered light at large-scattering-angles from the restriction of the aperture of the Fourier lens. The focal length is reduced to enhance the resolution of the instrument, and ring shaped of multi-element silicon photo-diode ensure gathering all the light signals of particles, highly improve the resolution.

2,Built-in dispersion units:

We carefully aligned the stirring set-up, the ultrasonic dispersing unit and the sample circulation pipes, and fixed them inside the instrument. Such a built-in design effectively prevents the inhomogeneous dispersion and sedimentation of big particles, which can be observed in the designs that these dispersing units are separated from the instruments, where the sample circulation pipes are therefore too long, The sample will be sufficiently dispersed.

3,Unconstrained free fitting analysis techniques:

The particle analysis software uses a unique unconstrained data fitting technique that we developed to obtain data of real particle size distribution, this is particularly important for researchers.

4,Micro sample chamber (optional):

The capacity of the sample chamber is as small as only 10ml. This helps with measuring expensive/precious samples, or samples difficult to be dispersed within medium.

5,Modern measurement control:(Intelligent SOP Operation)

Users can perform all measurement procedures by simply operating on the PC and have ideal results in a very short time.

6,User-friendly Operation:

manual mode and the automatic mode, freely choose, to measure according to the sample features. In some conditions (e.g. the sample have unknown features or there are special requirements for the measurements), users can make a test measurement in the manual mode first, and after having an idea of the sample features and the measurement conditions, measure the samples in the automatic mode.

7,Fully automatic light path alignment:

A precise four phase hybrid stepping motor automatically aligns the optical path and can adjust it at any moment, precision is up to 0.1um, This releases users from manual adjusting the optical path and improved accuracy and stability of the measurement results.

8,Quick measurements:

set “ automatic” mode, all operation procedures are performed automatically,automatic water supply, automatic ultrasonic sample, stirring, circulation,background testing, sample testing,analysis , draining and cleaning, which significantly reduces the time for measurements, the full process only take 2 minutes.

9,Data analysis:

Errors in the data are rejected and the measurement results are automatically processed. Manual data processing is not necessary and the output is more standard.

10,Sample cell automatic ultrasonic cleaning function

Secondary dispersion of easily agglomerated samples ensures the accuracy of test results, and reduces the cleaning times of sample cell to ensure that the sample cell remain clean always.

Specification

|

Model Name |

Winner2018 |

|

|

Standard |

ISO13320:2016, GB/T19077.1-2016, Q/0100JWN001-2013 |

|

|

Principle |

Laser diffraction principle |

|

|

Analysis |

MIE scattering theory |

|

|

Measuring Range |

0.1μm-450μm |

|

|

Channels Number |

40 PCS |

|

|

Accuracy error |

<0.5% ( CRM D50 ) |

|

|

Repeatability error |

<0.5% ( CRM D50 ) |

|

|

Light source |

High performance Semiconductor Laser (λ= 635nm, P>2MW)

|

|

|

|

Ultrasonic |

Frequency:40KHz Power:60W, Time: ≥1S |

|

Stir |

Revolutions Speed: 0-3000RPM (Adjustable) |

|

|

Circulate |

Rated Flow:8L/min Rated Power:10W |

|

|

Sample Pool |

Volume:350mL |

|

|

Micro-

|

Volume: 10mL ( Available) |

|

|

Operation Mode |

Full automatic and manual control, freely choose |

|

|

Output parameter |

D10,D50,D90,D100,S/V referent parameters |

|

|

Optical alignment system |

Full automatic |

|

|

Test Speed |

<2mins for each time, classical test speed <15S/time |

|

|

Volume |

L780mm×W365mm×H495mm |

|

|

Net Weight |

40Kg0 |

|

Principle

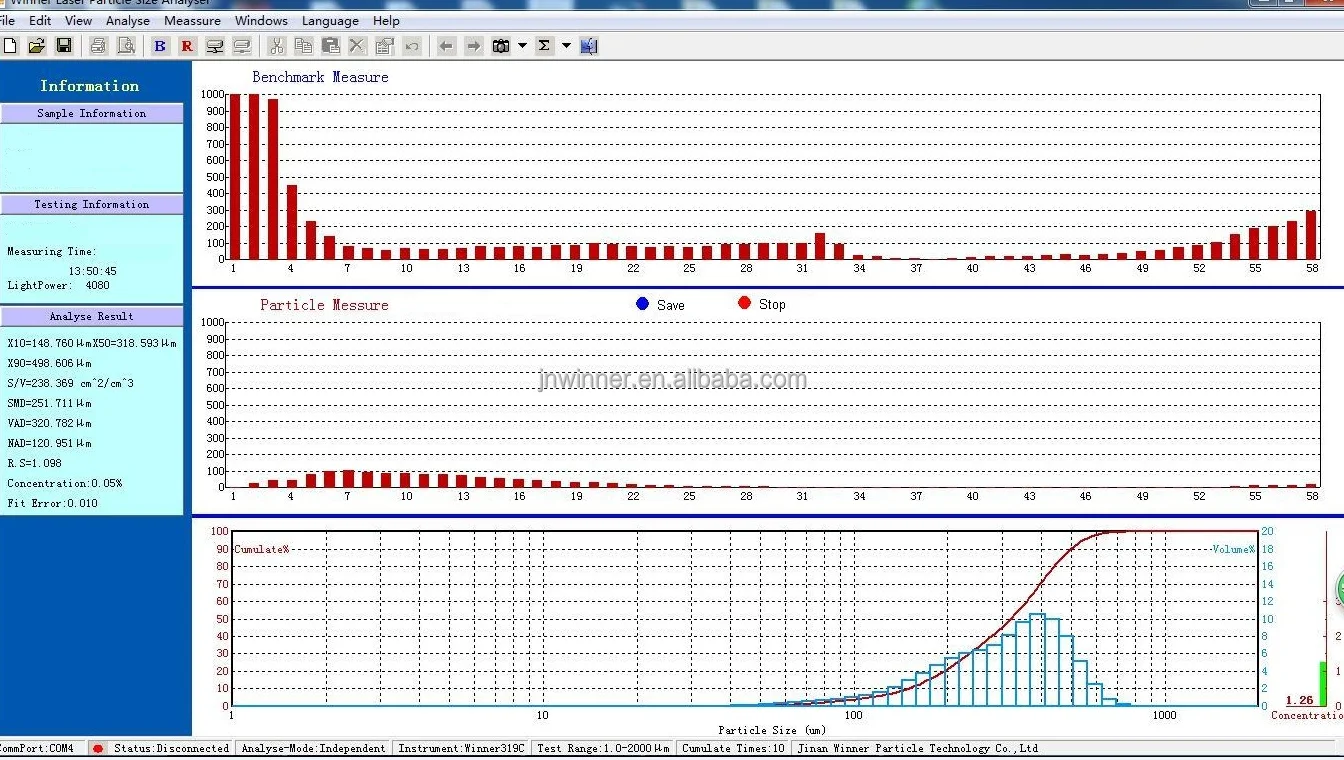

Test Operation Interface:

Quality Assurance

1. Strictly conforming to ISO9001-2000 quality management system.

2. Strict control from purchasing materials, process inspection to final particle size distribution test.

3. QC department to execute quality control regulations.

4.Only qualified components will be assembled and total laser particle size analyzer must be inspected completely before sale.

5.Laser particle size analyzer will be processed preventing -shake test before delivery.

After Sale Service

1.Operation demo video CD will be offered.

2. Offer free-training service.

3. The quality assurance date is 1 year since finishing payment, Technology support will be provided for life. And after that, we will collect the cost if provide repair accessories.

4. Maintenance for equipment failure caused by improper handling (appropriate cost will be collected).

5. We offer the components with favorable price and perdurable maintenance.