| Model: | Shutter door |

|---|---|

| Brand: | Wadley |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | cold-bending making , track roll forming , Shutter Door Roll Fo |

| Price: |

US $7500

/ pc

|

| Min. Order: | 3 pc |

| Last Online:08 May, 2024 |

Product Description

1、 Business sector Rolling shutter doors are widely used in the commercial field, mainly in the interior and exterior doors of shops, supermarkets, restaurants, banks, hotels, and other places. 2、 Industrial sector Roller shutter doors are also widely used in the industrial field. For example, factories, warehouses, logistics centers, and other places require large areas of doors. Traditional sliding doors and swing doors fix the site and have a large volume, while rolling shutter doors can be raised or lowered at any time, saving space. Moreover, roller shutter doors are mostly made of metal, which is sturdy and durable, and can withstand harsh weather conditions such as high temperature, cold, wind, and rain, ensuring the safety of property in the industrial field. 3、 Residential sector The application of rolling shutter doors in the residential field is becoming increasingly widespread, mainly used in the decoration of doors and windows such as villas, gates, garages, balconies, etc. Rolling shutter doors not only save space, but also have functions such as anti-theft, sound insulation, fire prevention, and insect prevention. In summary, roller shutter doors are a versatile and multifunctional decorative material for doors and windows. In addition to the above three areas, roller shutter doors are also suitable for entertainment venues, sports venues, basements, hospitals and other places.

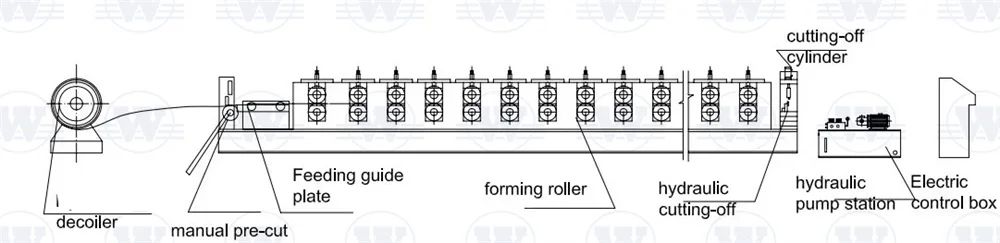

Working Flow: Uncoiling —— Material Feeding —— Roll Forming —— Step Making —— Automatic Cutting —— Products Receiving

Specification

|

item |

value |

|

Product name |

Shutter Door Roll Forming Machine |

|

Raw material |

Galvanized Coil |

|

Cutting blade material |

SKD11 heat treatment |

|

Roller material |

45#steel Chrome Plated |

|

Frame thickness |

14MM |

|

Shaft material |

45# Steel Outer Diameter: 50mm |

|

Cutting type |

Automatic Hydraulic Cutting |

|

Thickness |

0.3-0.6mm |

|

Color |

Cllent's Request |

|

Keywords |

Roller Shutter door making machine |

Choice of standard EU size or custom size:

Why Choose Us:

♥ Over 20 years of experience.

♥ Customized according to customer requirements with OEM ODE Services.

♥ Favorable price and easy operation.

♥ For many years, we have always adhered to quality first and service foremost, and have developed high-quality agents in

Chile,Brazil, Philippines, Malaysia,Indonesia, United States, Germany, Canada, Nigeria,Thailand,Cameroon, Romania and other countries.

♥ Professional technical team strictly controls every step of production to ensure the quality of each equipment.

♥ Provide technical guidance, production, installation, commissioning and maintenance services for our customers.

Good feedback:

Our factory's technical personnel provide technical training and guidance to foreign customers on site:

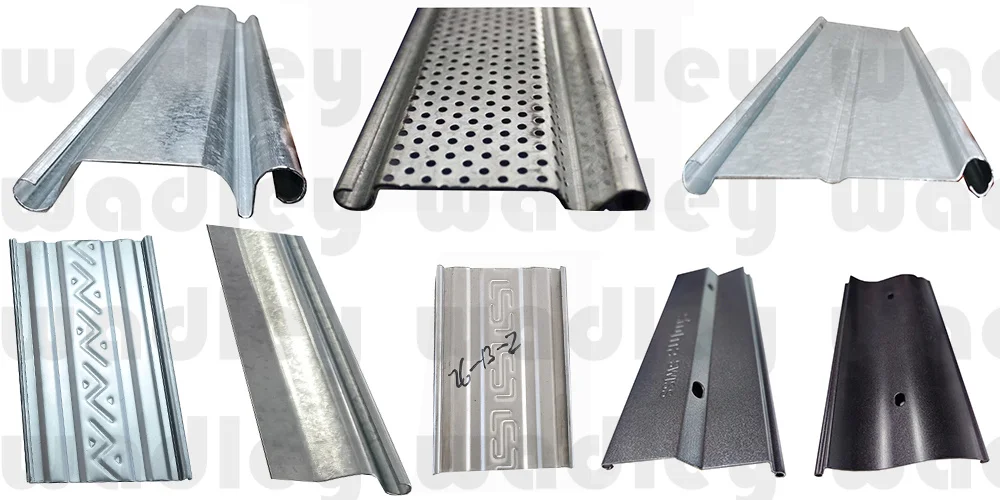

Accessories display

Packing & Delivery

1.Standard export wooden box packaging or 20ft or 40ft container;

2.Fit for ocean shipping;

3.The main body of the roll forming machine will be naked packing into the container,covered with plastic film.

4.Steel wire fix the machine into the container, in case any damage when shaking on the sea.

5.The spare parts will be packed into the carton box.

6.The received goods table put intocarton box .

7.Manual decoiler naked package.

Company Profile

FAQ

Q1, You are trade company or factory?

We are trade company but we also have own factories. Building trade company is just for exporting various types of cold roll forming machines.

Q2, Why your price is higher than others?

As we persist on that each factory should put quality at the first place. We spend time and money on developing how to make machines much more automatic, accurate and high quality. We can make sure that our machine could use more than 20 years without any problem. We can provide 2 years free quality assurance.

Q3, How long the machine could be made?

It usually takes 45-60 working days. Does one machine can only produce one style panel profile?

Not exactly.For wider and double layer making machine .It can produce more than 6 kinds of panels.

Q4, What is your after sales support?

We are happy to give advice and we also have skilled technicians available across the world.

Q5, What can you do if the machine broken?

1.The machine will be tested before shipment with coil, ensure everything is ready.

2.We will prepare some spare parts along with the machine, ensure our customer can solve the issue in a shortest time.Both the sale person and technician can give you the service overseas and make training for the workers,the sale person can make translation, so that the installtion and training will be more clear and easily.