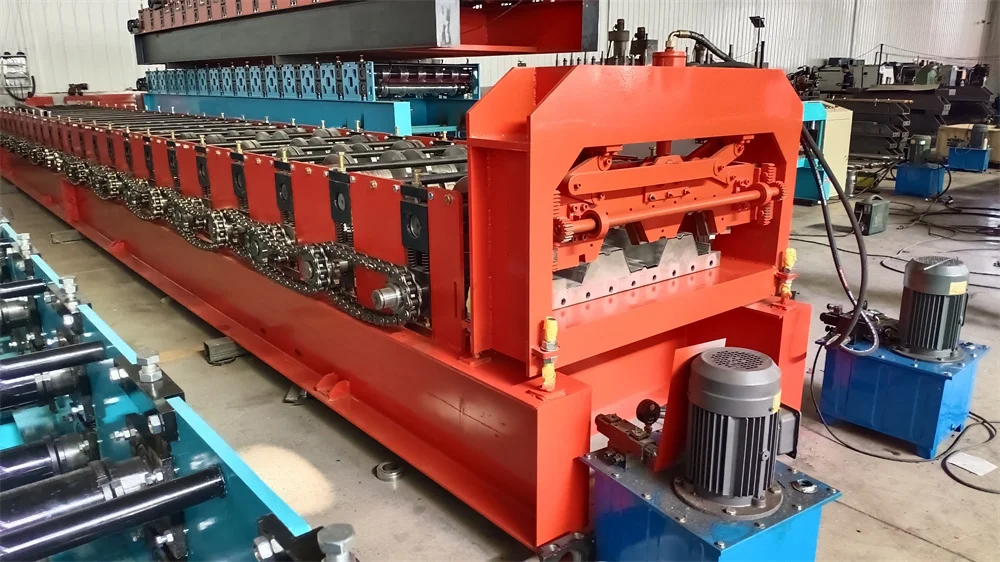

| Model: | Floor Deck Form |

|---|---|

| Brand: | Wadley |

| Origin: | Made In China |

| Category: | Industrial Supplies / Construction Machine |

| Label: | Cold Roll Forming Ma , Floor Deck Forming M , Floor Deck Roll Form |

| Price: |

US $25000

/ pc

|

| Min. Order: | 3 pc |

| Last Online:08 May, 2024 |

Production Description

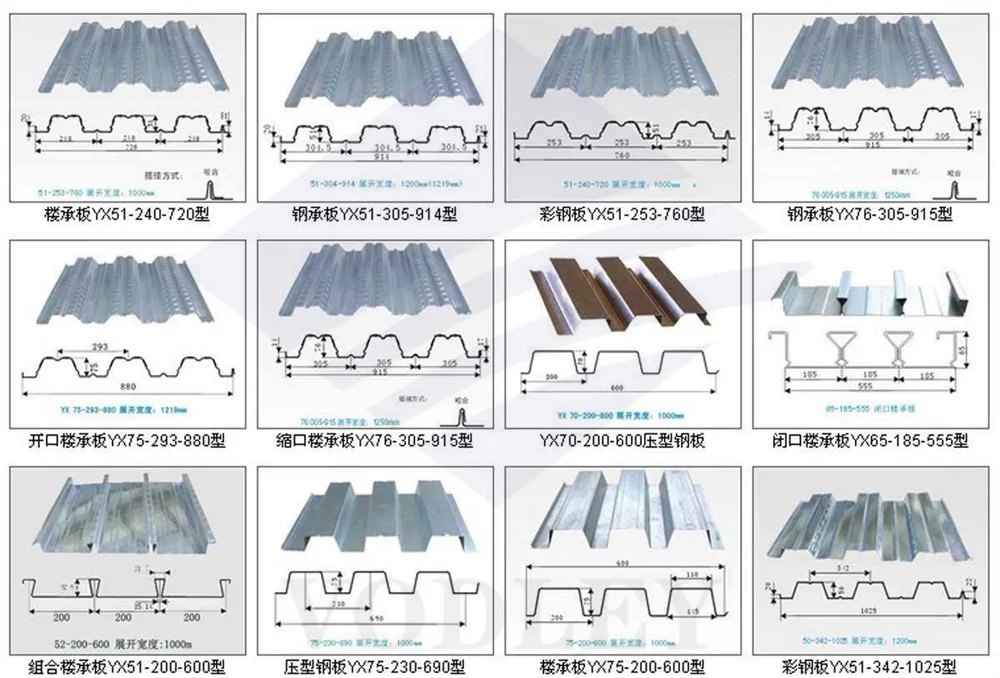

Manufacture zinc floor deck panel roof sheet tile roll former forming making machine

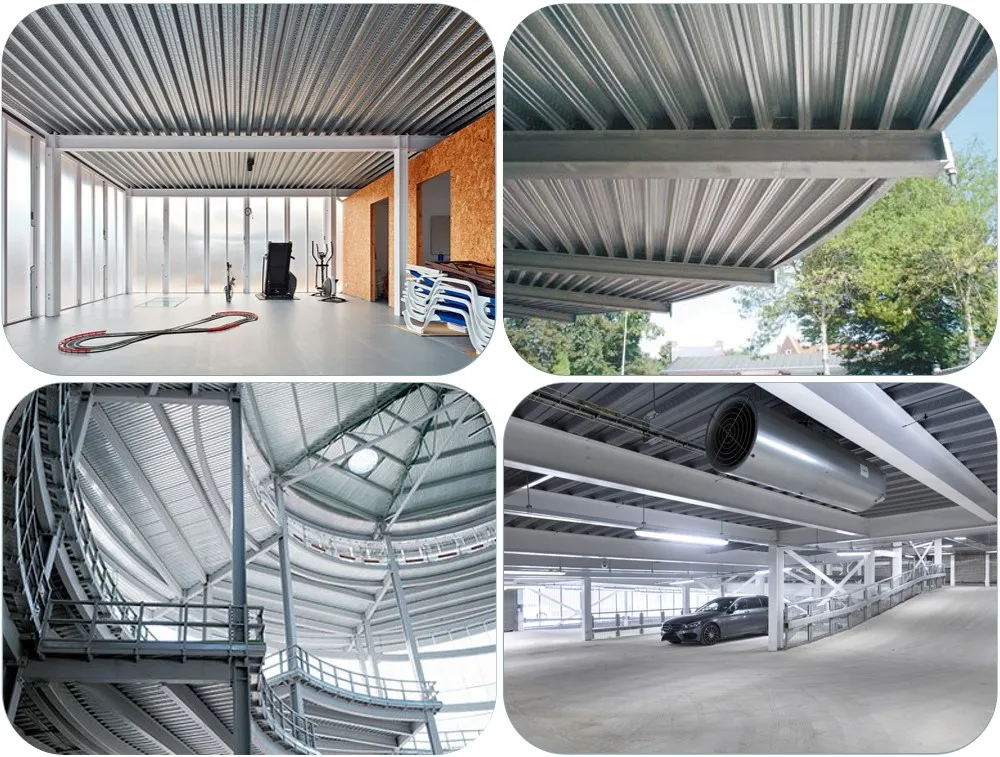

Floor support plates are widely used in steel structure buildings such as power plants, power equipment companies, automobile exhibition halls, steel structure factories, cement warehouses, steel structure offices, airport terminal buildings, train stations, sports venues, music halls, theaters, large supermarkets, logistics centers, Olympic venues and sports venues.

Adapting to the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short period of time, and can use multiple floors to lay profiled steel plates and layered pouring of concrete slabs for flow construction.

Product Specification

|

No |

Item |

Data |

|

1 |

Raw material width |

1000-1200 mm |

|

2 |

Sheet effective width |

750-1000 mm |

|

3 |

Raw material |

Color steel sheet or galvanized steel sheet |

|

4 |

Material thickness |

0.3-0.8 mm or customized |

|

5 |

Forming roller material |

45# steel plated with chrome |

|

6 |

Shaft diameter |

70 mm |

|

7 |

Forming roll station |

8-16 steps |

|

8 |

Main motor power |

3 KW 4 KW 5.5 KW(according to type) |

|

9 |

Hydraulic power |

4 KW (according to type) |

|

10 |

Control system |

PLC control |

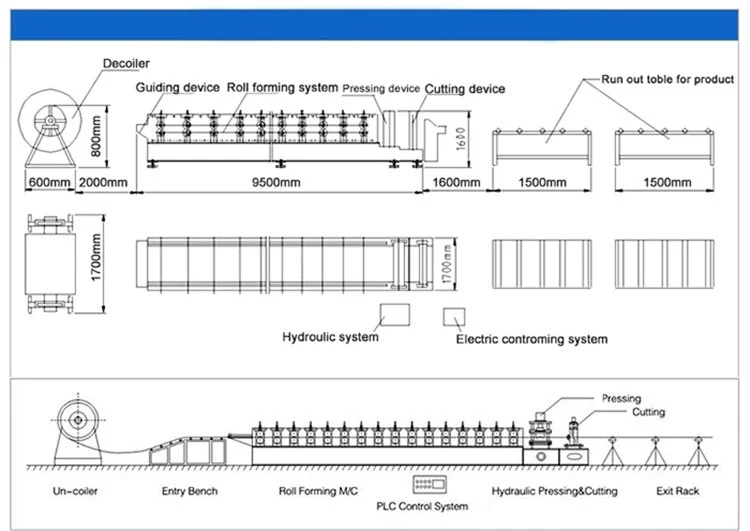

Material supporting frame→Molding core→Hydraulic system→Automatic control system→Automatic shearing mechanism→Roll forming→receiving tables

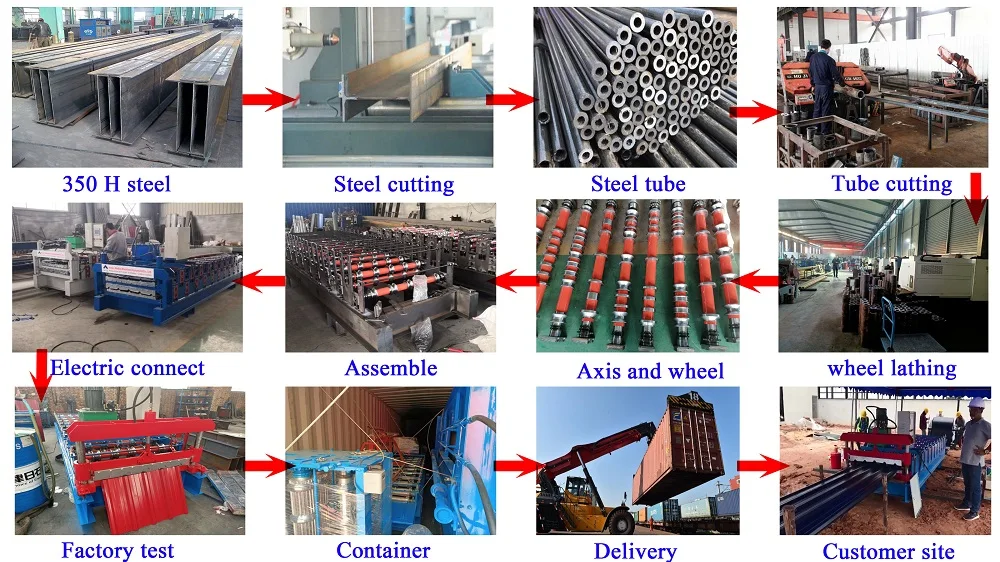

Packing List of steel floor decking sheet roll forming machine full automatic galvanized metal floor decking sheet panel

(1) Main Machine

(2) Hydraulic System

(3) Forming Cutter

(4) PLC Computer Controlling System

(5) Run Out Table

(6)Manual in English

Details Images

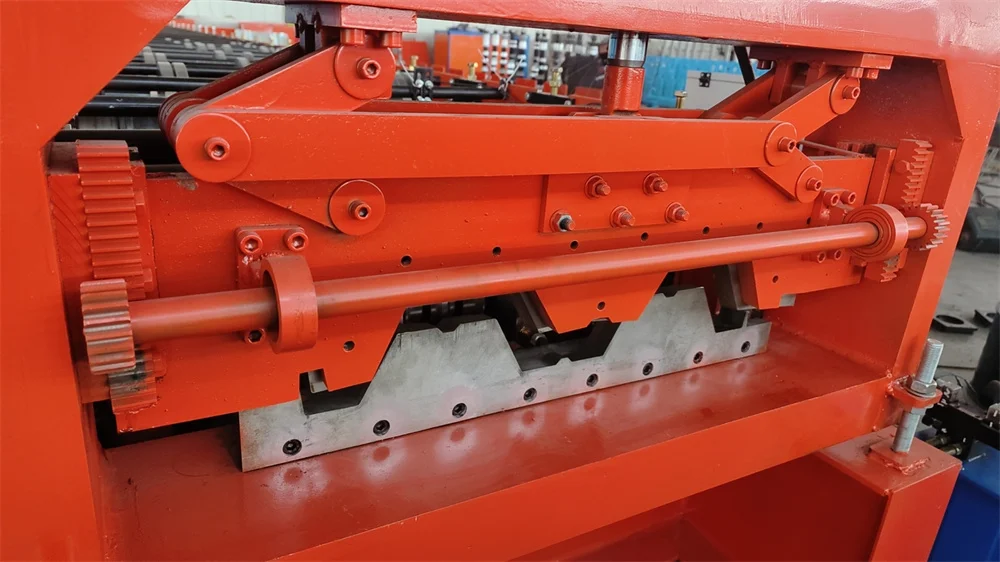

Blade of floor deck roll forming machine

The purpose of the shear is to cut the fixed length, head, tail, edge, sample and local defects of the rolled piece

Cutting Way:Hydraulic shear

Material of blade:Cr12

Counter of floor deck roll forming machineMainly to counting piece of tiles. If customer want produce 1 shape tile 5 pieces, counter will have memory to give signal to PLC, after 5 pieces reached, stop automatically, very automated.

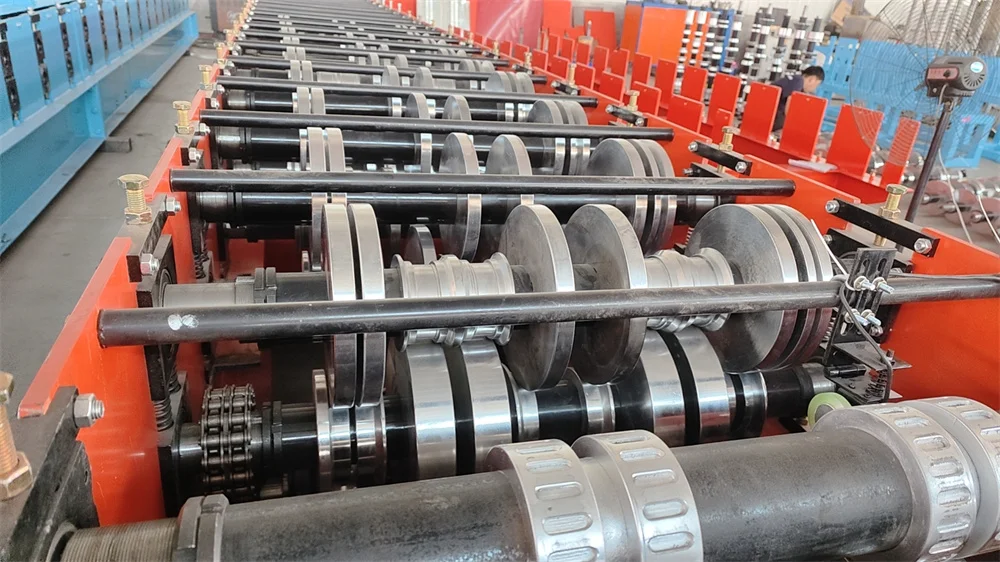

Forming roller of floor deck roll forming machine

The 90mm Cr12 forming wheel, combined with multiple rows of rollers, is sturdy and durable, and can perfectly press the desired finished product.

Control cabinet of floor deck roll forming machine

Independent electric control cabinet, which can be moved and placed according to needs; High definition screen, mechanical button control.

main features : 1: Adapting to the requirements of rapid construction of the main steel structure, it can provide a firm working platform in a short period of time, and can use multiple floors to lay profiled steel plates and layered pouring of concrete slabs for flow construction. 2: During the use stage, the floor support plate serves as the tensile steel bar for the concrete floor slab, which also improves the stiffness of the floor slab and saves the amount of steel and concrete used. 3: The surface embossing of the profiled plate creates the maximum bonding force between the floor bearing plate and the concrete, forming a whole between the two. With the addition of stiffeners, the floor bearing plate system has a high-strength bearing capacity. 4: Under cantilever conditions, the floor support plate is only used as a permanent template. The length of the cantilever can be determined based on the cross-sectional characteristics of the floor support plate. In order to prevent the cracking of the cantilever plate, negative reinforcement shall be provided at the support according to the design of the structural engineer.

Other design of tile making roll forming machine, we also could customized to you, just share us your details about:

1)Your details design of tile making roll forming machine.

2)Raw materials of tile making roll forming machine

3)Thickness of tile making roll forming machine

Related Products

Metal Roofing Sheet Roll Forming Machine:

single layer roof making machine

double Layers roof making machine

three layers roof making machine.

Customized Profiles Purlin Making Machine:

omega purlin making machine

U purlin making machine

C purlin making machine

Company Profile

Henan Wadley CNC Machinery Co.,Ltd..

Henan Wadley CNC Machinery Co.,Ltd. is a manufacture specializing in custom cold roll forming equipment and automatic production lines,we can manufacture hundred types roll forming machines and all kinds of architecture profliles. Engineers and technicians are rich in experience of designing developing and manufacturing of machines to provied customers with customized designs.Our products and sold to many countries and regions around the world.and we have established long-term cooperative relationships with customers. Main products: the company operates various types of products with various specifications, including cold bending forming equipment and other mechanical equipment, such as tile pressing machine, machine tool, tapping machine, slotting machine, boring machine, air hammer, gear hobbing machine, nail making machine, marking machine, etc. Wide range of products, welcome to inquiry.

VR

FAQ

Q1. What are the main key points for selecting right machines?

A1: Whole structure,Roller Shaft,Roller Material,Motor&Pump,and Control system. As the new buyer, please kindly know that price not the final point.Good quality is for long-term business cooperation.

Q2. Can you provide OEM service for roll forming machine?

A2: Yes, most of cold roll forming machine need to be customized as detailed request, because raw material , size , production usage, machine speed, then machine specification will be some different.

Q3. What’s your standard trade terms ?

A2: We can provide the technical offer with FOB,CFR,CIF,Door to Door and so on. Please kindly tell the detailed port name

for competitive ocean freight.

Q4. How about the quality control?

A4: Our company adopts 6S system to control every part with passed ISO9001:2000, CE,TUV/BV(Alibaba) Certificate.

Q5. How about the after-sale service?

A5: We provide 18 months free warranty and free technical support for the whole life of any machine. During warranty period, if parts still broken, we can send the new ones freely.