| Model: | SJ5780 |

|---|---|

| Brand: | CHOTEST |

| Origin: | Made In China |

| Category: | Electronics & Electricity / Electronic Instrument / Electronic Measurment Apparatus |

| Label: | thread measurement , profilometer |

| Price: |

US $1

/ pc

|

| Min. Order: | 1 pc |

| Last Online:21 Oct, 2024 |

Product Description

2D Profilometer - SJ5780

The SJ5780 bidirectional scanning profiler is a large-range, high-precision active scanning comprehensive profile measuring instrument. The instrument uses independent motion systems for the X-axis and Z-axis, and uses advanced two-axis linkage motion control algorithms to achieve X-axis and Z-axis linkage scanning. During measurement, the probe performs contour scanning (active scanning) on the surface of the workpiece, which not only maintains constant measuring force, but also ensures the ability to pass through large steep slopes. The workpiece leveling operation is simple, and problems such as needle collapse and needle hanging are avoided. It can scan continuously over a large range at full range, and has a continuous climbing ability of up to hundreds of millimeters. It is very suitable for measuring large-scale steep slope surfaces. Large workpieces can be easily measured without flipping or tilting.

Advantages

Parameters

| Model No. | SJ5780-200 | SJ5780-300 | SJ5780-400 | ||

| Basic

Spec. |

Measuring Range | X | 0~235mm | 0~325mm | 0~400mm |

| Z | 0~235mm | 0~325mm | 0~400mm | ||

| Min Resolution | 0.001μm | ||||

| Scanning Speed | 0.1~2mm/s | ||||

| Measuring Force | 10~150mN | ||||

| Max Slope | Uphill 78º, downhill 87º | ||||

| Y Direction Object Table | Travel range 25mm, Overall height 85mm(Motorized table is optional) | ||||

| Thread

Meas. |

Thread Measuring Range | Intenal: M3~M200, External: M3~M200(Determined by optional jigs) | |||

| Accuracy(Maj., Pit., Min. Diamter) | ≤±(4+L/100)μm, L is measured length in mm | ||||

| Accuracy(Thread Pitch) | ≤±(1 +L/100)μm, L is measured length in mm | ||||

| Profile

Meas. |

Diameter Measuring Range | Internal: φ3~Φ200, External: φ3~Φ200(Determined by optional jigs) | |||

| Diameter Measuring Accuracy | ≤±(3+L/100)μm, L is measured length in mm | ||||

| Profile Degree Accuracy | ≤±(2 +L/100)μm, L is measured length in mm | ||||

| Roughness

Meas. (Optional) |

Roughness Parameters | R Roughness:

Rp,Rv,Rz,Rc,Rt,Ra,Rq,Rsk,Rku,RSm,RPc,Rdq,Rdc,Rmr,Rmax,Rpm,tp,Htp,Pc,Rda,Ry,Sm,S,Rpc,RzJ; Key Roughness: Rk,Rpk,Rvk,Rpkx,Rvkx,Mr1,Mr2,A1,A2,Vo; Profle: Pa,Pq,Pt,Pz,Pp,Pv,PSm,Psk,Pku,Pdq,Pdc,Pc,PPc,Pmr,Rad,PzJ,Pmax; Waviness of Profile: Wa,Wg,Wt,Wz,Wp,Wv,Wsm,Wsk,Wku,Wdq,Wdc,Wmr,Wpc,Wc; Motif: R,AR,W,AW,Rx,Wx.Wte; |

|||

| Ra Measuring Range | Ra0.012μm~Ra12.5μm | ||||

| Filter | 2RC filtering, Gaussian filtering and Zero phase filtering | ||||

| Sampling Length | 0.008, 0.08, 0.25, 0.8, 2.5, 8.0, 25mm optional | ||||

| Evaluation Length | Automatic calculation | ||||

| Cutoff Wavelength | 0.25/0.8/2.5(mm) or User-defined cut-off | ||||

| Size(L×W×H) | 1200×500×980mm | 1200x500x1180mm | 1200x500x1180mm | ||

| Weight | 100kg | 200kg | 200kg | ||

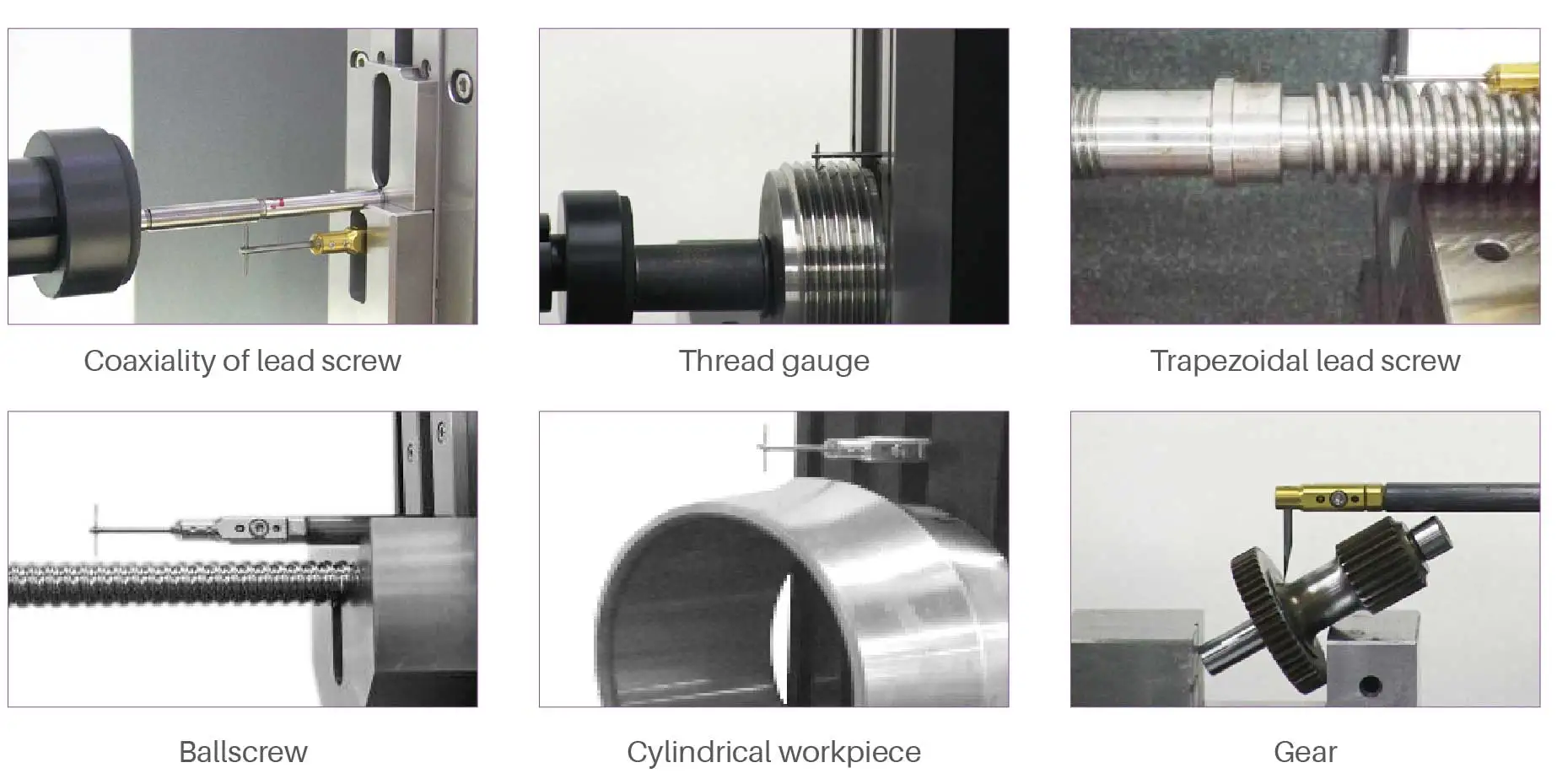

Applications

SJ5780 can be used for measuring the inner and outer diameter dimensions and inner and outer contour morphology parameters of high-precision parts such as long shafts, cylinders, curved parts, lead screws, and threads. It is very suitable for aviation, military industry, shipbuilding, high-speed rail, new energy vehicles, medical and other industries. This product supports range customization and is suitable for use in laboratories or work sites in various industries.