3.5英寸TFT液晶显示屏

General Specifications

LX350B4504 is a color active matrix LCD module incorporating

amorphous silicon TFT (Thin Film Transistor). It is composed of a color

TFT-LCD panel, driver IC, FPC and a back light unit. The module display

area contains 320x 480pixels. This product accords with RoHS

environmental criterion.

8.INSPECTION CRITERIA

8.1Inspection Conditions

8.1.1Environmental conditions

The environmental conditions for inspection shall be as follows

Room temperature: 20±3°C

Humidity: 65±20%RH

8.1.2 The external visual inspection

With a single 20-watt fluorescent lamp as the light source, the inspection was in the distance of 30cm

or more from the LCD to the inspector's eyes .

8.3 Classification of defects

9.3.1Major defect

A major defect refers to a defect that may substantially degrade usability for product applications.

9.3.2 Minor defect

A minor defect refers to a defect which is not considered to be able substantially degrade the product application or a

defect that deviates from existing standards almost unrelated to the effective use of the product or its operation.

10. PRECAUTIONS FOR USING LCD MODULE

10.1 HANDING PRECAUTIONS

(1) The display panel is made of glass. Do not subject it to a mechanical shock or impact by dropping it.

(2) If the display panel is damaged and the liquid crystal substance leaks out, be sure not to get any in your mouth. If

the substance contacts your skin or clothes, wash it off using soap and water.

(3) Do not apply excessive force to the display surface or the adjoining areas since this may cause the color tone to

vary.

(4) The polarizer covering the display surface of the LCD module is soft and easily scratched. Handle this polarizer

carefully.

(5) If the display surface becomes contaminated,breathe on the surface and gently wipe it with a soft dry cloth. If it is

heavily contaminated, moisten a cloth with one of the following solvents:

- Isopropyl alcohol

- Ethyl alcohol

(6) Solvents other than those above mentioned may damage the polarizer.

Especially, do not use the following:

- Water

- Ketone

- Aromatic solvents

(7) Extra care to minimize corrosion of the electrode. Water droplets, moisture condensation or a current flow in a

high-humidity environment accelerates corrosion of the electrode.

(8) Install the LCD Module by using the mounting holes. When mounting the LCD Module, make sure it is free of

twisting, warping and distortion. In particular, do not forcibly pull or bend the I/O cable or the backlight cable.

(9) Do not attempt to disassemble or process the LCD Module.

(10) NC terminal should be open. Do not connect anything.

(11) If the logic circuit power is off, do not apply the input signals.

(12) To prevent destruction of the elements by static electricity, be careful to maintain an optimum work environment.

- Be sure to ground the body when handling he LCD Module.

- Tools required for assembling, such as soldering irons, must be properly grounded.

-To reduce the amount of static electricity generated, do not conduct assembling and other work

under dry conditions.

-The LCD Module is coated with a film to protect the display surface. Exercise care when peeling off this protective

film since static electricity may be generated.

10.2 STORAGE PRECAUTIONS

When storing The LCD Module, avoid exposure to direct sunlight of fluorescent lamps. Keep the modules in bags

(avoid high temperature/ high humidity and low temperatures below 0℃). Whenever possible, the LCD Module should

be stored in the same conditions in which they were shipped from our company.

10.3 OTHERS

Liquid crystals solidify under low temperature (below the storage temperature range) leading to defective

orientation or the generation of air bubbles (black or white). Air bubbles may also be generated if the module is subject

to a low temperature.

If the LCD Module have been operating for a long time showing the same display patterns the display

patterns may remain on the screen as ghost images and a slight contrast irregularity may also appear. A normal

operating status can be recovered by suspending use for some time. It should be noted that this phenomenon does not

adversely affect performance reliability.

To minimize the performance degradation of the LCD Module resulting from destruction caused by static

electricity etc. exercise care to avoid holding the following sections when handling the modules.

- Exposed area of the printed circuit board.

- Terminal electrode sections.

11. USING LCD MODULES

11.1 LIQUID CRYSTAL DISPLAY MODULES

LCD is composed of glass and polarizer. Pay attention to the following items when handling.

(1) Please keep the temperature within specified range for use and storage. Polarization degradation, bubble generation

or polarizer peel-off may occur with high temperature and high humidity.

(2) Do not touch, push or rub the exposed polarizers with anything harder than a HB pencil lead (glass, tweezers, etc).

(3) N-hexane is recommended for cleaning the adhesives used to attach front/rear polarizers and reflectors made of

organic substances, which will be damaged by chemicals such as acetone, toluene, toluene, ethanol and isopropyl

alcohol.

(4) When the display surface becomes dusty, wipe gently with absorbent cotton or other soft material like chamois

soaked in petroleum ether. Do not scrub hard to avoid damaging the display surface.

(5) Wipe off saliva or water drops immediately, contact with water over a long period of time may cause deformation or

color fading.

(6) Avoid contacting oil and fats.

(7) Condensation on the surface and contact with terminals due to cold will damage, stain or polarizers. After products

are tested at low temperature they must be warmed up in a container before coming is contacting with room

temperature air.

(8) Do not put or attach anything on the display area to avoid leaving marks on.

(9) Do not touch the display with bare hands. This will stain the display area and degrade insulation between terminals

(some cosmetics are determinate to the polarizers).

(10)As glass is fragile, it tends to become or chipped during handling especially on the edges. Please avoid dropping or

jarring.

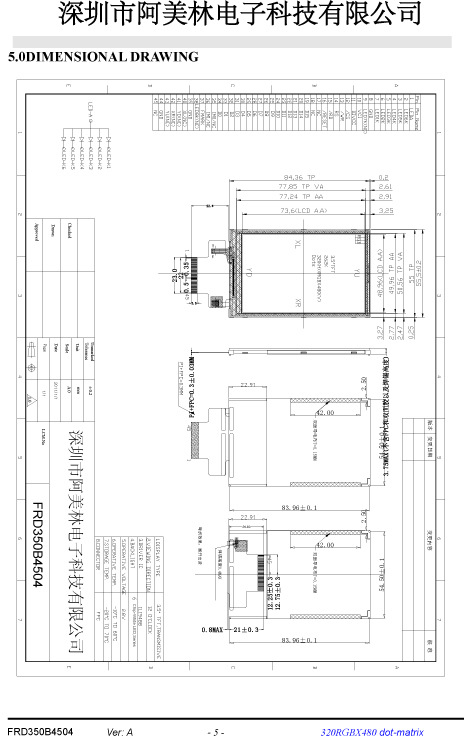

11.2 INSTALLING LCD MODULE

Attend to the following items when installing the LCM.

(1) Cover the surface with a transparent protective plate to protect the polarizer and LC cell.

(2) When assembling the LCM into other equipment, the spacer to the bit between the LCM and the fitting plate should

have enough height to avoid causing stress to the module surface, refer to the individual specifications for

measurements. The measurement tolerance should be ±0.1mm.

11.3 ELECTRO-STATIC DISCHARGE CONTROL

Since this module uses a CMOS LSI, the same careful attention should be paid for electrostatic discharge

as for an ordinary CMOS IC.

(1) Make certain that you are grounded when handing LCM.

(2) Before removing LCM from its packing case or incorporating it into a set, be sure the module and your body have

the same electric potential.

(3) When soldering the terminal of LCM, make certain the AC power source for the soldering iron does not leak.

(4) When using an electric screwdriver to attach LCM, the screwdriver should be of ground potentiality to minimize as

much as possible any transmission of electromagnetic waves produced sparks coming from the commutator of the

motor.

(5) As far as possible, make the electric potential of your work clothes and that of the workbenches to the ground

potential.

(6) To reduce the generation of static electricity , be careful that the air in the work is not too dried. A relative humidity

of 50%-60% is recommended.

11.4 PRECAUTION FOR SOLDERING TO THE LCM

(1) Observe the following when soldering lead wire, connector cable and etc. to the LCM.

-Soldering iron temperature: 280 ±10°C.

-Soldering time: 3-4 sec.

-Solder: eutectic solder.

If soldering flux is used, be sure to remove any remaining flux after finishing to soldering operation. (This

does not apply in the case of a non-halogen type of flux.) It is recommended that you protect the LCD surface with a

cover during soldering the prevent any damage due to flux spatters.

(2) When soldering the electroluminescent panel and PC board, the panel and board should not be detached more than

three times. This maximum number is determined by the temperature and time conditions mentioned above, though

there may be some variance depending on the temperature of the soldering iron.

(3) When removing the electroluminescent panel from the PC board, be sure the solder has completely melted, otherwise

the soldered pad on the PC board could be damaged.

11.5 PRECAUTIONS FOR OPERATION

(1) Viewing angle varies with the change of liquid crystal driving voltage (Vo). Adjust Vo to show the best contrast.

(2) Driving the LCD in the voltage above the limit will shorten its lifetime.

(3) Response time is greatly delayed at temperature below the operating temperature range. However, this does not

mean the LCD will be out of the order. It will recover when it returns to the specified temperature range.

(4) If the display area is pushed hard during operation, the display will become abnormal. However, it will return to

normal if it is turned off and then on.

(5) Condensation on terminals can cause an electrochemical reaction disrupting the terminal circuit. Therefore, it must

be used under the relative condition of 40°C, 50% RH.

(6) When turning the power on, input each signal after the positive/negative voltage becomes stable.

11.6 STORAGE

When storing LCDS as spares for some years, the following precaution are necessary.

(1) Store them in a sealed polyethylene bag. If properly scaled, there is no need for desiccant.

(2) Store them in a dark place. Do not expose to sunlight or fluorescent light, keep the temperature between 0°C and

35°C.

(3) The polarizer surface should not come in contact with any other objects. (We advise you to store them in the

container in which they were shipped.)

(4) Environmental conditions:

-Do not leave them for more than 168hrs. at 60 °C.

-Should not be left for more than 48hrs. at –20 °C.

11.7 SAFETY

(1) It is recommended to crush damaged or unnecessary LCDs into pieces and wash them off with solvents such as

acetone and ethanol, which should later be burned.

(2) If any liquid leaks out of a damaged glass cell and comes in contact with the hands, wash off thoroughly with soap

and water.

11.8 LIMITED WARRANTY

Unless agreed between FEIGEDA and customer, FEIGEDA will replace or repair any of its LCD and modules

which are found to be functionally defective when inspected in accordance with FEIGEDA LCD acceptance standards

(copies available upon request) for a period of one year from date of shipments. Cosmetic/visual defects must be

returned to FEIGEDA within 90 days of shipment. Confirmation of such date shall be based on freight documents. The

warranty liability of FEIGEDA is limited to repair and/or replacement on the terms set forth above. FEIGEDA will not

be responsible for any subsequent or consequential events.

11.9. RETURN LCM UNDER WARRANTY

No warranty can be granted if the precautions stated above have been disregarded. The typical examples of

violations are:

-Broken LCD glass.

-PCB eyelet’s damaged or modified.

-PCB conductors damaged.

-Circuit modified in any way, including addition of components.

-PCB tampered with by grinding, engraving or painting varnish.

-Soldering to or modifying the bezel in any manner.

Module repairs will be invoiced to the customer upon mutual agreement. Modules must be returned with

sufficient deion of the failures or defects. Any connectors or cable installed by the customer must be removed

completely without damaging the PCB eyelet’s conductors and terminals.