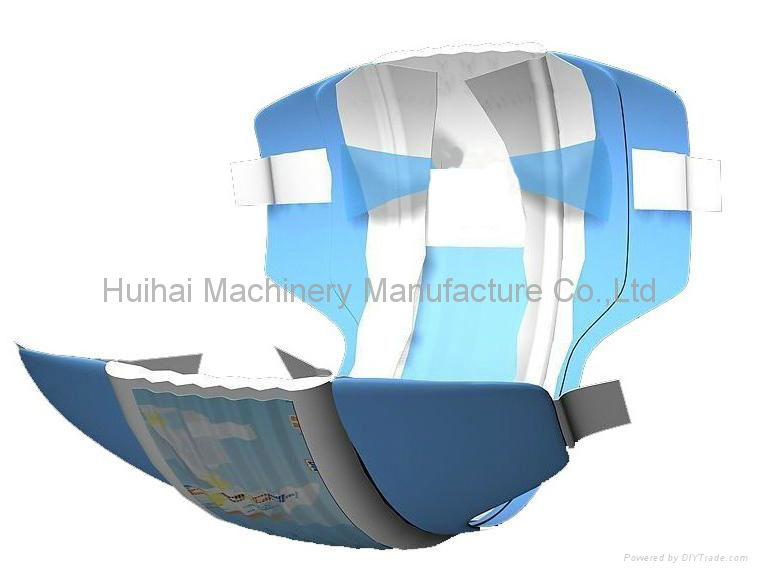

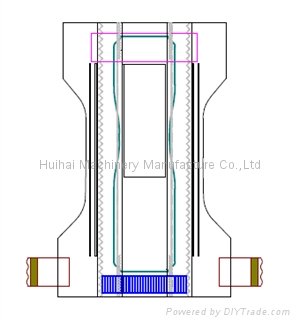

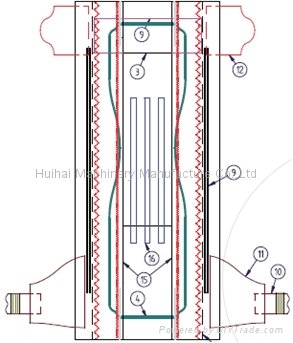

Basic Structure: Fluff core, top sheet, backsheet, frontal tape, side tape

Optional structure: Airlaid core, stand cuff, ADL, waistband, laminate NW, Stretched Ear tape(T-tape).

Main Function Features:

1. Servo motors driving system with PLC control and big touch screen

2. High -speed teeth - like crusher;

3. Web - wheel moulding;

4. SAP auto adding with amount control

5. Servo unwinding, auto - tension control and splicing for raw materials

6. Auto reject for wasted & rejected product, auto detect & alarm for material exhausted

7. Phase adjusting during running without stop

8. Diaper tri -folding or double folding

9. Diaper auto counting & stacking

10. 'S' cutting/magic side tapes

11. Security door equipped in operation side

| Performances |

|

| Volume (million pieces/ year) |

40-100 million pieces |

| Designed Speed |

500 pcs/min |

| Stable Speed |

300-450 pcs /min |

| 4. Passing rate |

≥ 97% (Not include the glue applicator, Auto Splicing) |

| |

|

| Technical Parameter: |

|

| Power Supply |

3 phase, 5 wires (380v, 50HZ) |

| Power Installed |

250KW include Glue filter |

| Power Used |

220KW |

| Electric wire |

3× 120mm 2 +1× 50mm 2 +1× 25mm 2 |

| Compressed Air Supply |

0.6~0.8Mpa |

| Compressed Air Absorption |

4000 Nl/min |

| Machine Size |

32.0m× 8.0m× 4.0m(L× W× H ) |

| Working Size |

39m× 9.0 × 5.0m (L× W× H ) |

| Machine Weight |

about 70 T(whole production line) |

| Machine Color: |

Huihai Blue ( confirm with customer) |

| Machine Direction: |

From Right to Left (can be designed as customer’ s demand) |

| Containers: |

4× 40 HQ containers, 1× 20GP container |

Finish Product Size: XL , L , M , S

( Based on Customer’ s requirement) |

|

Max |

Min |

| Length |

550mm |

350mm |

| Width |

350mm |

200mm |

| Environmental Data |

|

| Temperature |

10 - 35° C |

| Humidity |

55% RH ± 5 |

| Noise Level (Measured at a distance of 1 meter) |

≤ 87 dB |