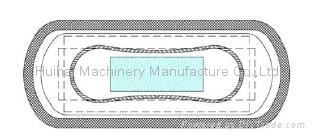

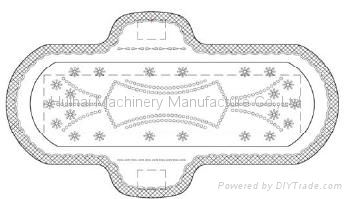

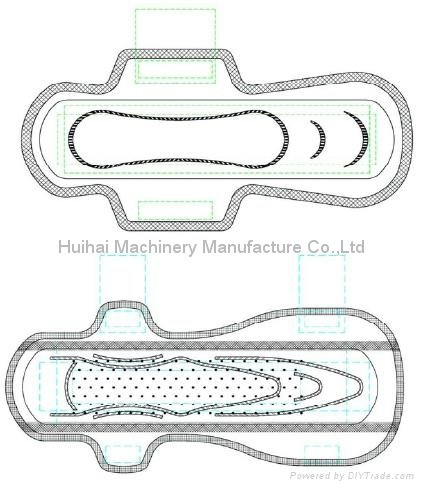

Basic Structure:

Fluff core, SAP, top sheet, backsheet, back tape, Wing tape

Optional structure:

Airlaid core, Non-wing shape, coverstock dotting, textile edge, stand cuff, transfer layer, elastic wing, Tri-fold pack, Easy pack, others to be discussed.

Main Function Features

1. Servo motors driving system PLC control and touch screen

2. High-speed teeth-like crusher

3. Web wheel moulding

4. SAP auto adding with amount control

5. Servo unwinding, auto-tension control and splicing for materials

6. Auto reject for wasted & rejected product, auto detect & alarm for material exhausted

7. Phase adjusting, during running without stop

8. Product auto counting & output in line

MAIN MACHINE COMPONENTS:

-cellulose unwinder

-hammermill

-drumforming

-SAP applicator

-Dust filter

-Piping

-Fans

-Unwinders

-Acquisition layer unit

-Silicon paper applicators

- Trifolding unit

- Individual wrapping unit

- Sealing unit

- Stacker infeed conveyor belts

- Counting/stacking unit

- Nordson Hot Melt glue applicator

| Main Technical Parameter: |

| Type: |

H-HY900-SV |

| 1. Designed production speed: |

220m/min |

| 2. Stable production speed: |

200m/min |

| 3. Machine power: |

3 phase, 5 wires (380v, 50HZ) |

| 4. Machine capacity: |

about 160KW(exclude hot melt applicators and air compressor) |

| 5. Machine size: |

24.0m× 7.0m× 3.5m(L× W× H ) |

| 6. Machine weight: |

about 25T (whole production line) |

| 7. Air pressure: |

0.6~0.8Mpa |

| 8. Passing rate: |

≥ 98% |