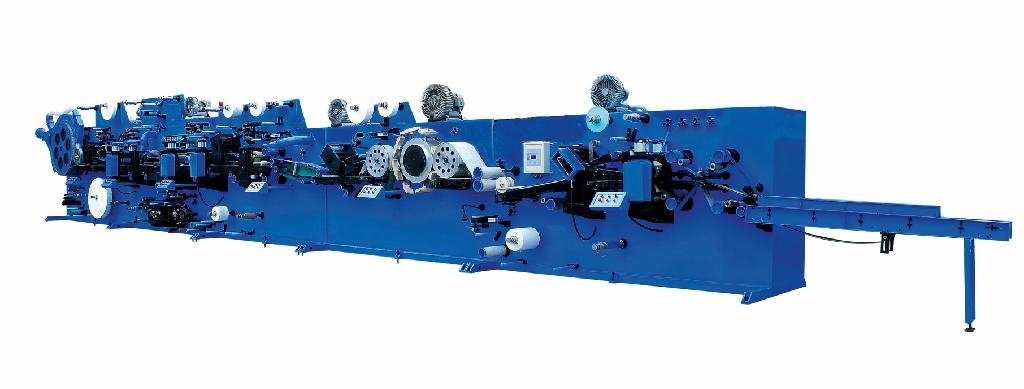

| Model: | WD-HY400-FC |

|---|---|

| Brand: | Welldone Machinery |

| Origin: | Made In China |

| Category: | Industrial Supplies / Daily Products Machine |

| Label: | sanitary napkin mach , lady napkin machine , napkin mahcine |

| Price: |

US $10000

/ pc

|

| Min. Order: | 1 pc |

Product Description

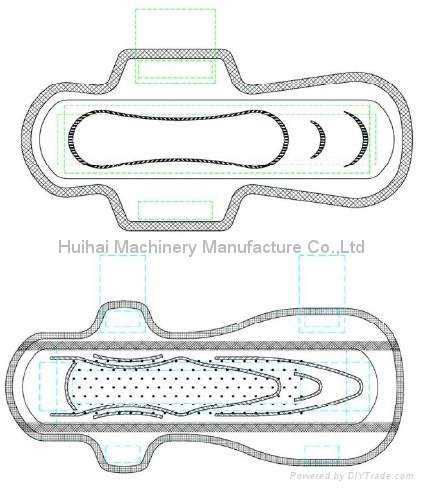

Basic Structure:

Fluff core, SAP, top sheet, backsheet, back tape, Wing tape

Optional structure: Airlaid core, Non-wing shape, coverstock dotting, textile edge, stand cuff, transfer layer, elastic wing, Tri-fold pack, Easy pack, others to be discussed.

MAIN MACHINE COMPONENTS:

-cellulose unwinder

-hammermill

-drumforming

-SAP applicator

-Dust filter

-Piping

-Fans

-Unwinders

-Acquisition layer unit

-Silicon paper applicators

- Trifolding unit

- Individual wrapping unit

- Sealing unit

- Stacker infeed conveyor belts

- Counting/stacking unit

Main Function Features

1. Frequency motors driving system control

2. High-speed teeth-like crusher

3. Web wheel moulding

4. SAP auto adding with amount control

5. Inverter unwinding, constant auto-tension control and splicing for materials

6. Phase adjusting, during running without stop

8. Product auto counting & output in line

| Main Technical Parameter: | |

| Type: | H-HY400 |

| 1. Designed production speed: | 140m/min |

| 2. Stable production speed: | 120m/min |

| 3. Machine power: | 3 phase, 5 wires (380v, 50HZ) |

| 4. Machine capacity: | about 120KW(exclude hot melt applicators and air compressor) |

| 5. Machine size: | 18.0m× 7.0m× 3.5m(L× W× H ) |

| 6. Machine weight: | about 20T (whole production line) |

| 7. Air pressure: | 0.6~0.8Mpa |

| 8. Passing rate: | ≥ 97% |

| Price Terms: | FOB Xiamen |

|---|---|

| Payment Terms: | TT/LC |

| Packing: | Antirust Oil& PE Film Cover & Wooden Case |

| Lead Time: | 100 DAYS after receiving the 30% deposit by TT |

| SKU: | order |

| Standards Certificate: | SGS,CE |

| HS Code: | 8441809000 |

| Automatic Grade: | semi automatic |

| Computerized: | yes |

Member Information

| Quanzhou Welldone Corporation | |

|---|---|

| Country/Region: | Fu Jian - China |

| Business Nature: | Manufacturer |

| Phone: | 18659800016 |

| Contact: | Steven Tang (Manager) |

| Last Online: | 18 Dec, 2013 |

Related Products of this Company

-

WD-YNK550A-Semi Servo Baby Diaper

US $10000

-

WD-HY800-SV Full Servo Sanitary Napkin

US $10000

-

WD-HY900 Full Servo High Speed Sanitary

US $10000

-

WD-CD-SV Disposable Under Pad Machine

US $10000

-

WD-YNK500-FC Frequency High Speed Baby

US $10000

-

WD-YNP600-SV Full Servo Baby Pad Machine

US $10000

-

WD--JTZ-B Toilet Paper Machine

US $10000

-

WD-CRNK-SV Full Servo Adult Diaper

US $10000

-

WD-MJZ-CS Face Tissue Machine

US $10000

-

WD-ZXD ABD Pad Machine

US $1