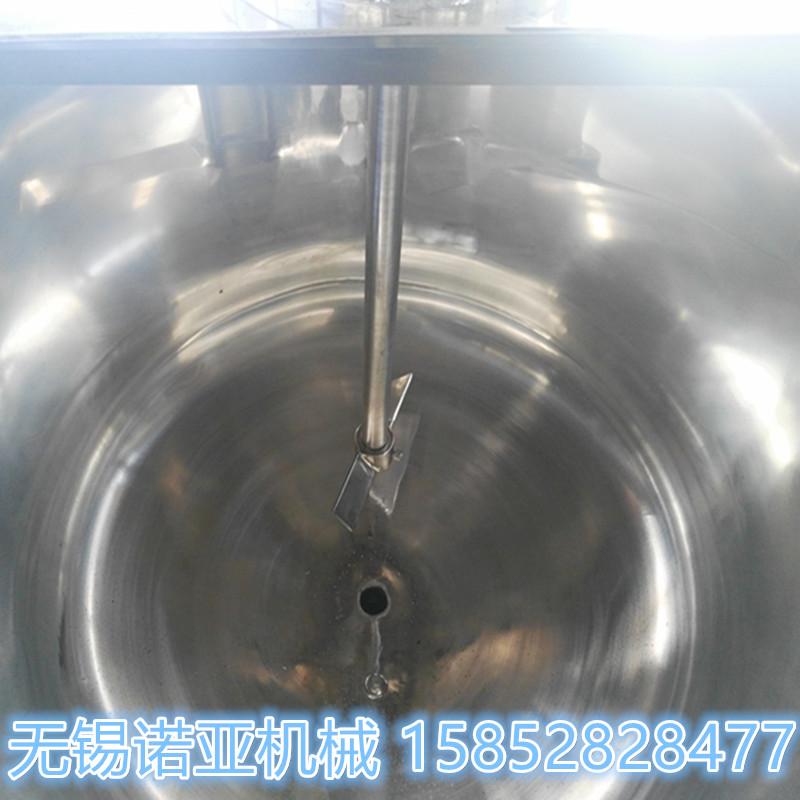

Wuxi Linam is a professional manufacturer of vacuum emulsifier, at the price. Quality. After-sales service and other aspects have certain advantages. 1. The main structure of the vacuum emulsifier factory produced by the main pot, water phase pot, oil phase pot, rack, electrical system, hydraulic system, vacuum system and heating system. The main pot is composed of a homogenizing stirring pot, a high shear homogenizing mechanism, a two-way mixing mechanism, a pot bottom discharge valve, a temperature control head and other structures. 2. The main features of the vacuum emulsifier produced by the factory are that the raw materials of the vacuum emulsifier are pretreated in the water and oil phase pot, and are sucked into the main pot by means of vacuum suction. In the main pot, the material is cut and crushed by a high-speed rotating homogenizer with 2800 R/min, and the material is stirred up and down with a two-way stirring frame, so that the material can be fully mixed, refined and crushed to 2um ~ 200 nm. The mixing frame of the laboratory emulsifier is equipped with a polytetrafluoroethylene scraper, thus ensuring that the material does not stick to the wall, does not remain, does not have the dead angle, truly conforms to the manufacturer’s GMP requirements. 3. The vacuum emulsifier produced by the manufacturer is mainly used in the production of cream products for cosmetic and pharmaceutical enterprises. In addition, also often used in food, daily chemical, chemical and other enterprises of material refinement, crushing. As the materials in contact with the materials are high-quality SUS304 or SUS316L stainless steel, so it also has a safe, materials are not contaminated! By the majority of users love. If you have any questions about the vacuum emulsifier products, please contact Wuxi Linam Company for details!