| Model: | LXG1/20 |

|---|---|

| Brand: | Longsun |

| Origin: | Made In China |

| Category: | Industrial Supplies / Rubber & Plastics Machine |

| Label: | blowing machine , blow molding machine , blow moulding |

| Price: |

-

|

| Min. Order: | 1 pc |

Product Description

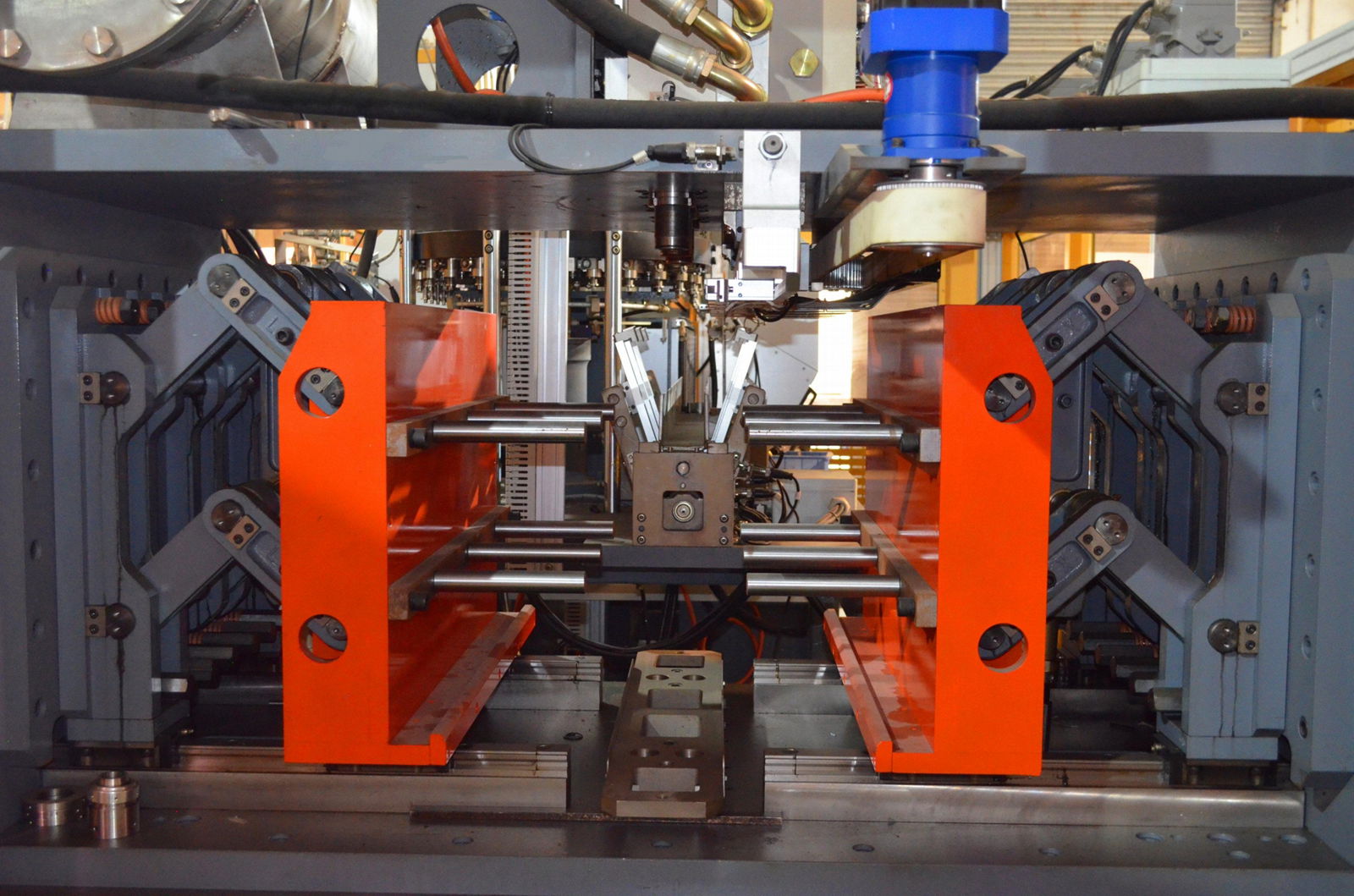

LXG- 2/20 Auto Bottle Blowing Machine Feature

1.1 Preform Feeding & Handling system

- Continuous preform feeding system

- Proper preform stabilization time on star-wheel before spindle insertion

- Composite aluminum alloy chain: strong, no wear, low maintenance cost

- Self-lubricate bushing and sealed bearing

- Ejection system for oval or not well inserted preforms

- Quick-change system (option) in less than 5 minutes for different neck diameters: change of loading wheel and loading guides

1.2 Preform Heating System

- Perfect heating system design helps decrease the power consumption.

- Special oven design helps power saving and is easy maintain.

- Preform heating system with laminar flow.

- Low thermal inertia: higher heating process consistency and fast start-up

- Oven dimensions based on preform and max bottle size (from 8 to 16 lamps)

- Modular oven

- Adjustable position for neck change

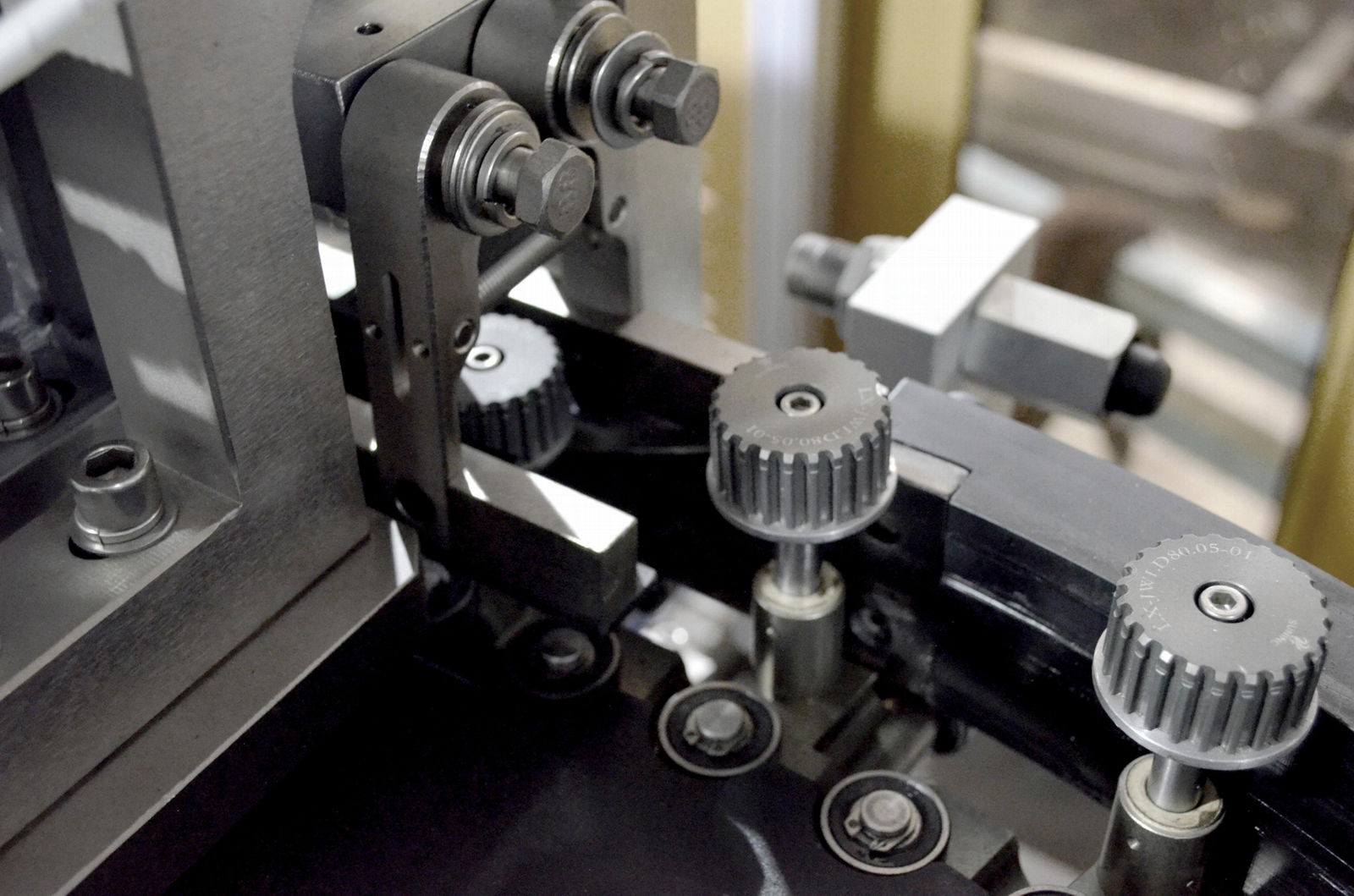

1.3 Preform Transfer & Pitch Change

- Servo-driven pitch-change system to optimize heating efficiency (oven pitch) and maximum bottle diameter (blowing pitch)

- Simple and reliable system

- Servo-driven unit for same-time preform and bottle transfer

- Precise and gentle preform holding

- Very high transfer speed

- Quick change of personalized parts (tool-less)

1.4 Stretching & Blowing

- Electrically driven blowing clamp, no oil

- Servo-driven motion with levers and oscillator

- High clamp speed

- Double-sided pneumatic compensation

- Servo driven stretch rods

- Fine setting of stretch profile thanks to servo control

- Blow seals, fast and independent for every cavity

- Self-learning of stretch stroke based on preform-bottle size

- High tech blowing valves: fast and independent for every cavity, with individual pre-blow flow regulation

- Very quick exhaust

- Standard Air tanks for peak blowing ramp, providing higher output

- By-pass valve to avoid chilled water when not in production

- Less power consumption once machine is in idle mode or is waiting for downstream

- No condensation on blow moulds once the machine is not blowing bottles

1.5 Bottle Ejection

- Servo-driven unit for bottle placed

- Can connect with air conveyor or belt conveyor or vacuum conveyor

- Bottle base cooling option

LXG-1/20 machine main parameter

|

|

Item |

LXG-1/20 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Main machine |

Maximum Bottle capacity |

20L |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Maximum bottle diameter |

Φ290mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Neck diameter |

Φ40~70mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Maximum bottle height under neck |

<500mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Stretching stroke |

<550mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Clamping stroke |

320mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Bottom die stroke |

50mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Bottle pitch |

400mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Maximum output rate (bph) |

700 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Number of molds |

1 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Heating part |

Number of heating modules |

6 |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Number of heating lamps |

12 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Number of preform bases |

44 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Electric part |

Voltage |

380V |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Frequency |

50Hz |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Service power |

30~60kw/h |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Installation power |

150kw |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Air source |

High pressure |

3.5Mpa |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

High pressure air consumption |

9m³/min |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Chilled water (Water temperature ≤30℃) |

Pressure |

4bar |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Flux |

6m³/h |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Weight |

G.W. |

Around 7,000kg |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Dimension |

Main machine (L×W×H) |

3600×2100×3300mm |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Preform unscrambler(L×W×H) |

3200×2500×3400mm |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Remarks: * 600bph output rate base on 15L round water bottle. * High pressure air consumption depends on PET bottle volume, altitude etc. * With high-pressure air recycle system.

Main electric component list

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Payment Terms: | TT/LC |

|---|---|

Member Information

| Dongguan Longsun Machinery Co., Ltd. | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13925564658 |

| Contact: | Perry (Sales Director) |

| Last Online: | 25 Jul, 2022 |