| Model: | 123 |

|---|---|

| Brand: | HL |

| Origin: | Made In China |

| Category: | Industrial Supplies / Machinery / Separation Equipment |

| Label: | Bucket elevator , screw conveyor , auger conveyor |

| Price: |

US $100

/ set

|

| Min. Order: | 1 set |

Product Description

1.Product introduction

TD type is according to JB3926-85 "vertical bucket elevator" design and manufacturing standards, currently the common bucket elevators are vertical, newer. Bucket elevator is suitable for vertical conveying powder, granular and small block and smaller abrasive bulk materials, such as grain, coal, cement, crushed ore, the maximum lifting height is 40m.There are four kinds of hopper of the TD-type bucket elevator: : Q-type (shallow bucket), H-type (arc bottom bucket), ZD type (deep bucket), SD type (deep bucket).

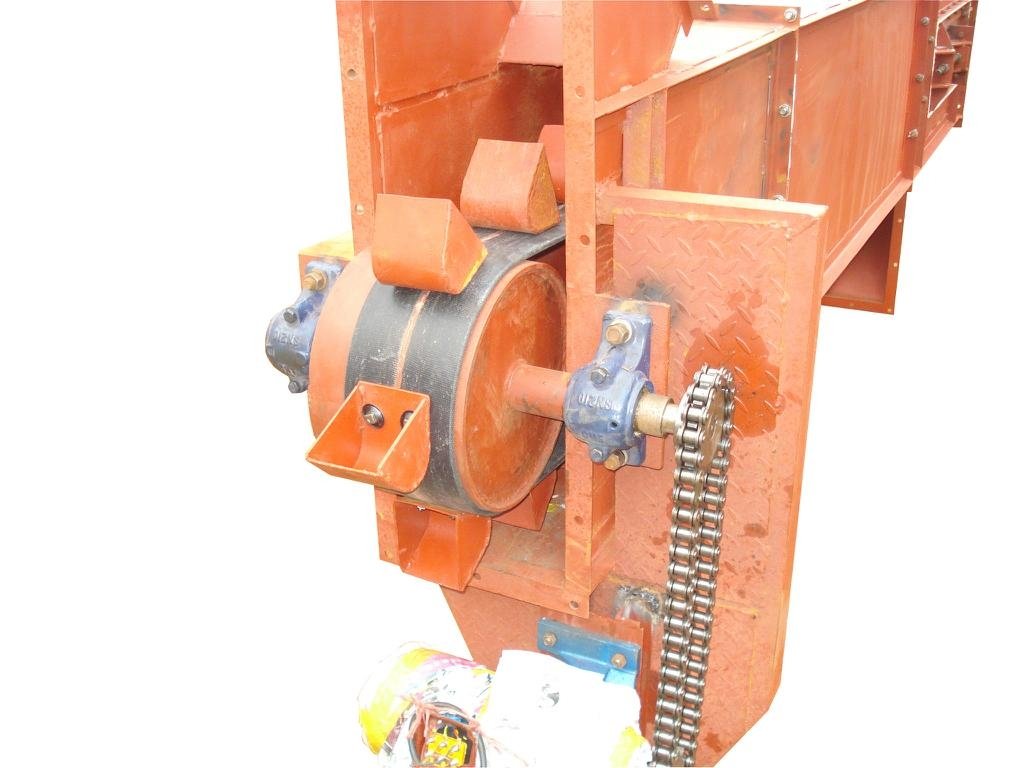

2. The basic structure

The TD-type bucket elevator is made up of running part (hopper and traction tape), the upper section with a driving drum, the lower section with a taut drum, intermediate casing, driving device, Non-return braking device and so on, it is suitable for conveying non-abrasive and semi-abrasive bulk materials whose density <1.5t / m³ with powder, granular and small block, such as coal ,sand , late coke, cement, crushed ore.

The structure of the TD-type bucket elevator: There is two type forms of the gear of the TD-type bucket elevator, It is respectively YZ type reducer, ZQ (YY) type reducer. YZ-type shaft reducer shaft directly mounted on the spindle head, eliminating the transmission platform, couplings and so on, so that making the structure is compact, lightweight, in addition, there is heterosexual roll backstop in its interior, reliable backstop. The reducer is low noise, smooth operation, and with the floating spindle, eliminating installation capacity.

3.The mail features

1) drive power is small, Adopted flow-through type feeding, induction feeding, large capacity hopper intensive layout. There is Almost no material back and dig material phenomena in the material hoist, therefore less reactive power.

2) Ascension is wide, This type bucket elevator have less demands for the types and performance of materials, it can not only improve the general powdery, granular materials, but also enhance the larger abrasive materials, sealing, and less environmental pollution.

3) Run reliability, advanced design principles and processing methods to ensure the reliability of the machine operation ,and its no down time is more than 20,000 hours. High lifting height, upgrade machines running smoothly, so you can upgrade to a higher level .

4) Long use time, taking the feeding inflow style of the bucket elevator, without using excavating bucket, rarely occurs squeeze and collision phenomenon between materials. The machine was designed to ensure that the material rarely spilled in the feed, unloading, reducing mechanical wear.

4.TD bucket elevator main technical parameters

|

Model |

TD160 |

TD250 |

TD315 |

TD400 |

|||||||||||||

|

Hopper Type |

Q |

H |

zd |

sd |

Q |

H |

zd |

sd |

Q |

H |

zd |

sd |

Q |

H |

zd |

sd |

|

|

Throughput(m³/h) |

5.4 |

9.6 |

9.6 |

16 |

12 |

22 |

23 |

35 |

17 |

30 |

25 |

40 |

24 |

46 |

41 |

66 |

|

|

Bucket width(mm) |

160 |

250 |

315 |

400 |

|||||||||||||

|

Bucket capacity(L) |

0.5 |

0.9 |

4.2 |

1.9 |

1.3 |

2.2 |

3 |

4.6 |

2 |

3.6 |

3.8 |

5.8 |

3.1 |

5.6 |

5.9 |

9.4 |

|

|

Bucket from t(mm) |

280 |

350 |

360 |

450 |

400 |

500 |

480 |

560 |

|||||||||

|

Width(mm) |

200 |

300 |

400 |

500 |

|||||||||||||

|

Doo-speed(m/s) |

1.4 |

1.6 |

1.6 |

1.8 |

|||||||||||||

|

Amount of material chunks(mm) |

25 |

35 |

45 |

55 |

|||||||||||||

|

Model |

TD500 |

TD630 |

TD160 |

TD250 |

TD350 |

TD450 |

|||||||||||

|

Hopper Type |

Q |

H |

zd |

sd |

H |

zd |

sd |

Q |

S |

Q |

S |

Q |

S |

Q |

S |

||

|

Throughput(m³/h) |

38 |

70 |

58 |

92 |

85 |

89 |

142 |

4.7 |

8 |

18 |

22 |

25 |

42 |

50 |

72 |

||

|

Bucket width(mm) |

500 |

630 |

160 |

250 |

350 |

450 |

|||||||||||

|

Bucket capacity(L) |

4.8 |

9 |

9.3 |

15 |

14 |

14.6 |

23.5 |

0.65 |

1.1 |

2.6 |

3.2 |

7 |

7.8 |

14.5 |

15 |

||

|

Bucket from t(mm) |

500 |

625 |

710 |

300 |

400 |

500 |

640 |

||||||||||

|

Width(mm) |

600 |

700 |

200 |

300 |

400 |

500 |

|||||||||||

|

Doo-speed(m/s) |

1.8 |

2 |

1 |

1.25 |

1.25 |

1.25 |

|||||||||||

|

Amount of material chunks(mm) |

60 |

70 |

25 |

35 |

45 |

55 |

|||||||||||

| Payment Terms: | TT/LC |

|---|---|

Member Information

| Xinxiang Hongli Machinery Co.,LTD | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 13598739530 |

| Contact: | Bruce (Sales) |

| Last Online: | 16 Feb, 2014 |

Related Products of this Company

-

Supply vibrating screen

US $100

-

Supply high-frequency vibrating screen

US $1

-

Supply drum vibrating screen

US $100

-

Supply rotary vibrating screen

US $500

-

Supply Direct discharging screen

US $1

-

Supply ore vibrating screen

US $100

-

Supply powder vibrating screen

US $100

-

Supply Linear vibrating screen

US $1

-

Supply tumbler vibration screen

US $500

-

Supply Screw conveyor

US $1