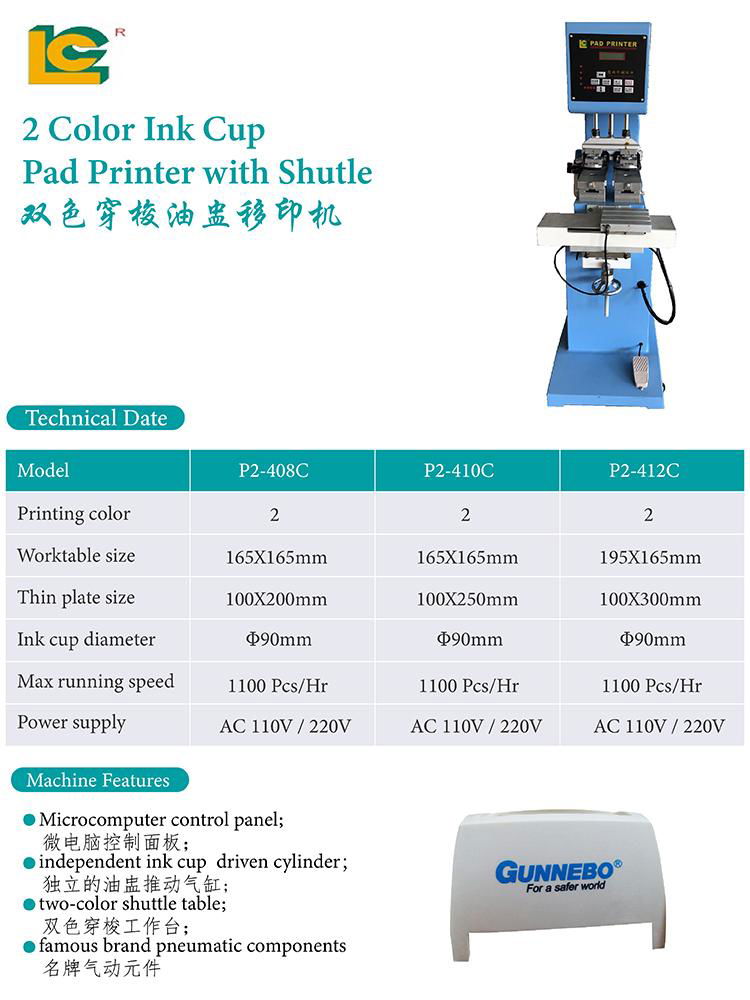

| Model: | P2-412C |

|---|---|

| Brand: | LC |

| Origin: | Made In China |

| Category: | Industrial Supplies / Plate Making & Printing Machine |

| Label: | pad printer , pad printing machine , pad press |

| Price: |

US $3044

/ pc

|

| Min. Order: | 1 pc |

Product Description

The environmental protection appeal of the pad printing machine is to use the ink supply method of the oil cup, and the ink is sealed in the oil cup to avoid the volatilization of the solvent. Two-color ink cup pad printers are the best-selling pad printers. Although high-end users will require pad printers with touch screens and more configurations, ordinary microcomputer-controlled pad printers and shuttle pad printers still occupy a large market. market share.

Two-color shuttle ink cup pad printers are introduced to the market with the size of the installed steel plate as a series. The larger the size of the steel plate, the larger the printing area. Widening the size of the steel plate in the horizontal direction means that a larger diameter oil cup needs to be selected. Extending the size of the steel plate in the transverse direction means that the size of the product that can be printed is larger. When you choose a pad printing machine, it is very important to provide your supplier with pictures of the product, dimensions, size and location of the printed pattern. In any case, if you are just getting into the field of pad printing, choosing a two-color shuttle pad printer is the most basic and probably the most cost-effective investment.

|

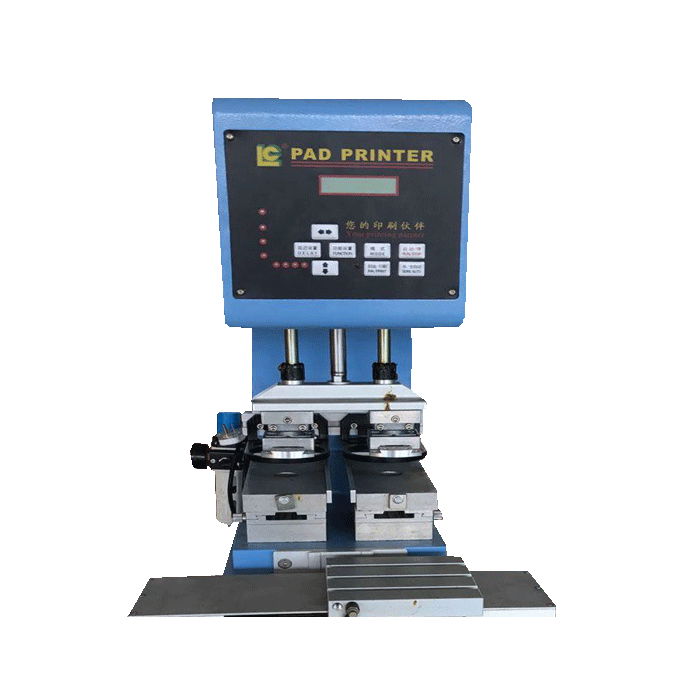

Two colors pad printer with shuttle//Structure |

|

|

Working table |

Two stations Shuttle-type working table |

|

Shuttle stroke |

125mm |

|

Ink supply system |

Closed -type system |

|

Plate type and size |

10mm Thick steel plate. |

|

Pad dropping control |

Simple-cylinder , simultaneously pressing |

|

Ink drying |

Heat air |

|

Two colors pad printer//Usage and characters |

|

|

Guide |

|

|

Application fields |

Electrons, hardware, autos, toys, gifts, Plastics, household appliances, artwork, stationery, adornment, cosmetic, commodity, sport goods, decorative lightings, woodwork, office supplies, Photo Materials, Kitchen utensils, Hotel supplies, Computer, Mobile, etc., industrial field. |

|

Two colors pad printer with shuttle//Parameter |

|

|

Technical parameters |

P2-408C |

|

|

| P2-410C | |

|

|

| P2-412C | |

|

|

|

Works supply |

|

|

Package list |

|

|

H.S.Code |

8443198000 |

|

Certicate |

CE |

|

Two colors pad printer with shuttle//Advantage |

|

|

Function |

|

| Summary: | The environmental protection appeal of the pad printing machine is to use the ink supply method of the oil cup, and the ink is sealed in the oil cup to avoid the volatilization of the solvent. Two-color ink cup pad printers are the best-selling pad printers. Although high-end users will require pad printers with touch screens and more configurations, ordinary microcomputer-controlled pad printers and shuttle pad printers still occupy a large market. market share. Two-color shuttle ink cup pad printers are introduced to the market with the size of the installed steel plate as a series. The larger the size of the steel plate, the larger the printing area. Widening the size of the steel plate in the horizontal direction means that a larger diameter oil cup needs to be selected. Extending the size of the steel plate in the transverse direction means that the size of the product that can be printed is larger. When you choose a pad printing machine, it is very important to provide your supplier with pictures of the product, dimensions, size and location of the printed pattern. In any case, if you are just getting into the field of pad printing, choosing a two-color shuttle pad printer is the most basic and probably the most cost-effective investment. |

|---|---|

Member Information

| LC industrial company Limited | |

|---|---|

| Country/Region: | Guang Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 13592766499 |

| Contact: | Mr kelven bai (Sales Manager) |

| Last Online: | 08 Nov, 2024 |

Related Products of this Company

-

Shuttle pad printer(P2-404)

US $1750

-

UV exposure machine

US $1323

-

Manual Large -Press Precision Hot

US $1354

-

Shuttle pad printer (SP4-406)

US $2941

-

Tank Conveyor style pad printer

US $4228

-

Precision Tank-Conveyor PLC robot pad

US $10000

-

Shuttle pad printer( PM2-250L)

US $3323

-

Plastics bucket screen printing

US $3235

-

Shuttle pad printer (SP4-606)

US $4676

-

Stand pad printer(P1-610)

US $2617