| Model: | Φ1.2*1.0m |

|---|---|

| Brand: | XBM |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | rotary dryer , drying machine , coconut drying machi |

| Price: |

US $19000

/ pc

|

| Min. Order: | 1 pc |

Product Description

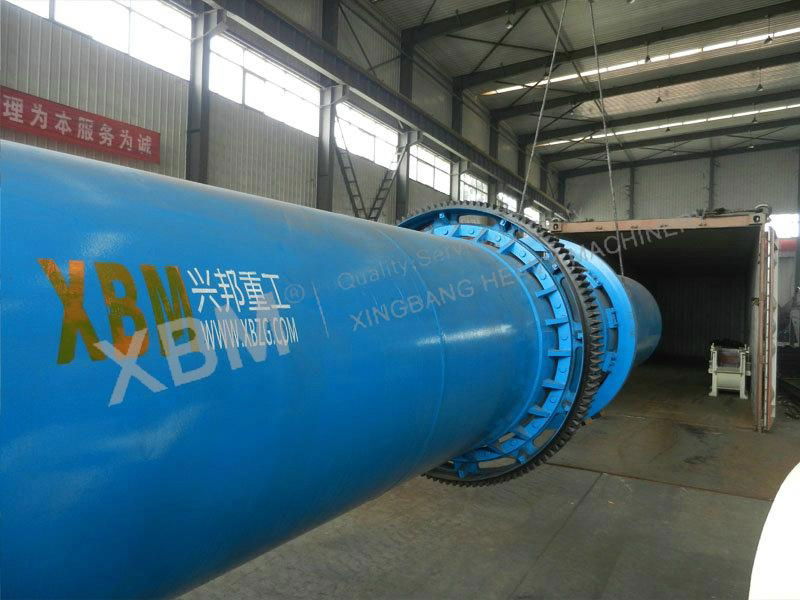

Cheapest Mineral Processing rotary coal dryer kiln

Henan XBM specialize in rotary coal dryer kiln,20 years experiences,professional design,first-class quality ,sales lead !

We offer rotary coal dryer kiln spare parts for free for the top five customers every month !

We offer rotary coal dryer kiln spare parts for free for the top five customers every month !

Advantages of China top professional mineral processing rotary coal dryer kiln

A. Value, high performance-price ratio

rotary coal dryer kiln are commonly used for heat processing of minerals and aggregates.XBM rotary coal dryer kiln can maintain a uniform product temperature at the kiln entry, mid zone and discharge to achieve consistent quality results. In most rotary coal dryer kilns, the challenge with temperature process control is that the temperature sensor must view through flames or heavy smoke and dust. Consequently,our engineer pay more attention to the selecting of sensor,no matter the design, wavelength, and alignment. They are all very important considerations, has greatly increased the value and high performance-price ratio of our rotary coal dryer kiln.

B.Widely capacity meet differents clients' needs( Part technical parameters of XBM rotary coal dryer kiln for your reference)

C. Professional technical team guarantee the precise inclination

For example,the model 2.2x50 rotary coal dryer kiln demands the inclination is4%, the rotation speed is0.125-1.25r/min; the model 1.8x45 rotary coal dryer kiln demands the inclination is3.5%, the rotation speed is0.66-1.98r/min, the pricise inclination in order that the rotary coal dryer kiln can work smoothly.

rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln

rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln rotary coal dryer kiln

D.The own characteristics of the rotary coal dryer kiln

1. Good sealing

2. Less easy worn parts

3. Convenient maintenance

4. All instrument control, reliable operation

E.The structure and working principle of XBM rotary coal dryer kiln

rotary coal dryer kiln is composed of cylinder, gears, support device, kiln liner and kiln tail sealing equipment, kiln head hood and combustion. Cylinder as heated pivoting part, made of high quality carbon steel plate, is supported on the support device by tire, and there is mechanical or hydraulic pressure catch wheel on the first or some gear in order to control the turning of cylinder. To prevent cold air come in and dust overflow, the reliable kiln tail and head sealing equipment is installed on feed and discharge end.

The kiln is a cylindrical vessel, inclined slightly to the horizontal, which is rotated slowly about its axis. The material to be processed is fed into the upper end of the cylinder. As the rotary coal dryer kiln rotates,material gradually moves down towards the lower end, and may undergo a certain amount of stirring and mixing.

F.More details of the XBM rotary coal dryer kiln

Brief introduction of XBM rotary coal dryer kiln: rotary coal dryer kiln is mainly used for metallurgy, building materials, ores and other mineral materials, heating and calcining. Such as ceramic sand, bauxite, limestone, cement, fly ash magnesium aluminum hydroxide, aluminum products, alumina refractory materials such as mineral particles and the heating and calcined powder.

The rotary coal dryer kiln can be divided into lime kiln, metallurgy chemical kiln and cement kiln according to different materials. Lime kiln is used for baking active lime and dolomite in the steel factory and ferroalloy factory.Cement kiln is used for making of cement clinker and there are dry and wet methods to make cement. Metallurgy chemical kiln is used for magnetic roasting of iron ore and oxidizing roasting of chrome and nickel in the steel factory; baking high-alumina mine in the refractory material factory; baking chamotte and alumina in the aluminium factory and baking chrome ore and chrome powder in the chemical plant.

G. Have authority certifications

H.The safety of the packaging and delivery

After we signed the purchase contract and have a certain reputation guarantee, we will contact the professional group that responsible for ship bookings, commodity inspection, commercial invoices, packing list, insurance policy and so on, in order to provide you the perfect goods trading services, until the active lime rotary coal dryer kiln you purchased properly to your hands.

I.The clients sites of our rotary coal dryer kiln

Kindly note:Please Inform us the follow figures:1).feeding material 2).Feeding material MAX. Size (mm) 3).Final mesh size (mm) 4).Capacity (t/h)

J. Considerate post-sales services

K.Our mining machine hot selling all over the world,and got the highly recognize of our customers

L.Often cooperation shipping company

All Xingbang people sincerely welcome talents and customers all over the world to come and visit our factory!

Looking forward to cooperating with you about our excellent rotary coal dryer kiln !

Tel:86-13683809990

Best Service Biggest sincerity Trustworthy

Member Information

| Henan Xingbang Heavy Machinery Co., Ltd. | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 36218067 |

| Contact: | Eric Cheung (manger) |

| Last Online: | 27 Feb, 2014 |

Related Products of this Company

-

Circular vibrating screen used for

US $5900

-

XBM Hot Sale Corn Rotary Dryer With

US $38000

-

High Efficiency Low Energy Consumption

US $1900

-

China Professional Primary mobile jaw

US $5600

-

High performance durable hammer stone

US $2800

-

high quality and Excellent performance

US $300

-

Economical 6-S Gold Separation Shaking

US $1200

-

Potential Benefits of XBM Mineral Spiral

US $1000

-

Newest High Efficiency vsi vertical

US $9800

-

High Efficiency Gold Mining Flotation

US $6000