| Model: | 2GP600 |

|---|---|

| Brand: | XBM |

| Origin: | Made In China |

| Category: | Industrial Supplies / Mining Machine |

| Label: | roller crusher , rolling machine , double roller |

| Price: |

US $1900

/ pc

|

| Min. Order: | 1 pc |

Product Description

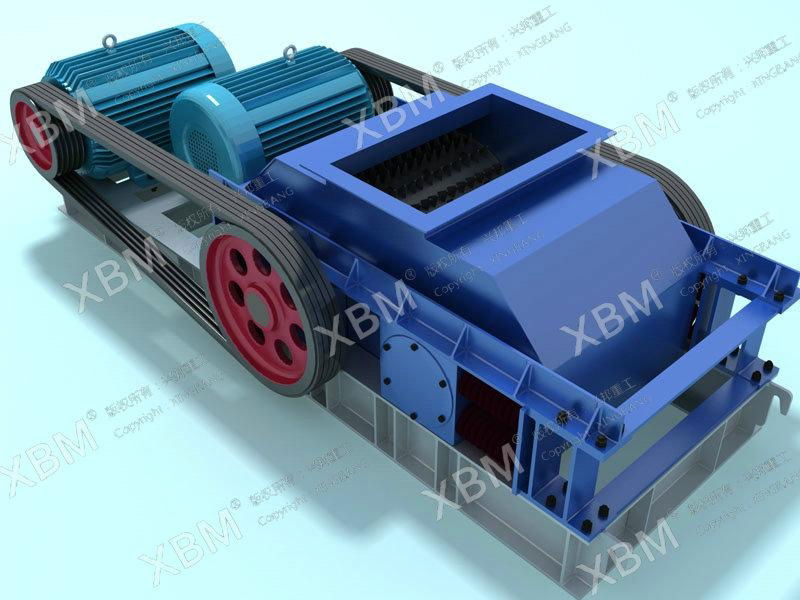

High Efficiency Low Energy Consumption double roller stone crusher

Introduction to Roll crusher

double roller stone crusher series is designed to be used in the industrial branches of ore dressing, chemical engineering, cement, building material and so on for medium and fine reduction of various ores and rocks with medium hardness and compression strength not greater than 120-150Mpa.

The fact without fixed product size says that fine crushing may be changed into medium crushing. Main features of the double roller stone crusher are higher ratio of need size, lower Capacity than of our impact crusher.

Application of double roller stone crusher

The rollers crusher is widely used for secondary and fine crushing in the industry of mining, building materials, chemical industry, metallurgy and so on. It can crush materials in middle hardness such as rocks, ore, coke, lump coal, slag, mineral slag, cement clinker, fireproof materials, and so on.

Features of clay brick double roller stone crusher:

Structural optimization: structure compact novelty, adopting single drive at low speed, operating steady, action roller movement is transferred by fixed roller through dentition.

Energy saving: just only using a set of power transmission to satisfy comminution requirement, which can save over 45% power than dual drive roller press.

High operation rate: perfect the avoidance device of foreign matter in-put. Action roller can avoid tough foreign matter in-put flexible and comfortable and solve roller severe wear’s drawback of dual drive roller press, which is caused by transmission failures.

Shipment to Qingdao Port

Price Negotiation

Sure, we are factory and be able to offer you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any client, and discount can be given according to quantity”.

After-sale Service:

1. Setting up customer records, knowing well the location and running state of the sold equipment, return visit time and contact information; Dispatching professional after-sales service staff to the site to help customers install and adjust equipment. 1-2 technicians are needed to assist customers in site-manufacturing for 1 month until customers are satisfied.

2. Keeping a record of the daily information from hot-line and its handling.Announcing the customers whose equipments have been over warranty period in time; Informing them of the maintaining details at regular intervals.

3. As to customer complaints out of non-quality reasons, customer managers should work with after-sales staff to analyse and explain problems caused by personal factors, make up and restore the damaged parts, implement operation guiding and training among customers' operators.

| Model | Roller diameter

(mm) |

Roller length

(mm) |

Max.feeding

size (mm) |

Discharging

size (mm) |

Capacity

(t/h) |

Roller

number |

Roller

rotation speed (r/min) |

Total weight

(t) |

Dimensions

(L*W*H) (mm) |

| 2PG400*250 | 400 | 250 | ≤25 | 2-8 | 5-10 | 2 | 180 | 2.2 | 1215*834*830 |

| 2PG610*400 | 610 | 400 | ≤25 | 0.5-30 | 13-40 | 2 | 75 | 5.9 | 3700*1600*1100 |

| 2PG700*400 | 700 | 400 | 100 | 0.5-30 | 10-100 | 2 | 95 | 9.8 | 3700*1600*110 |

Why Choose Us?

1.Over 20 years experience in this field;

2.Exported to more than 30 countries in Africa, Asia, America;

3.Processional Research and Development team; Strict quality control;

4.Provide complete service equipment installation, testing ,maintenance and staff training.

Member Information

| Henan Xingbang Heavy Machinery Co., Ltd. | |

|---|---|

| Country/Region: | He Nan - China |

| Business Nature: | Manufacturer |

| Phone: | 36218067 |

| Contact: | Eric Cheung (manger) |

| Last Online: | 27 Feb, 2014 |

Related Products of this Company

-

Energy Saving Wet Ball Mill Price in

US $38000

-

Economical 6-S Gold Separation Shaking

US $1200

-

Henan Xingbang vibrating feeder

US $1000

-

Circular vibrating screen used for

US $5900

-

2014 XBM High Capacity and Energy Saving

US $150000

-

High Efficiency Gold Mining Flotation

US $6000

-

XBM Hot Sale Corn Rotary Dryer With

US $38000

-

XBM Hot Sale sugar bucket elevator With

US $1000

-

high quality and Excellent performance

US $300

-

Henan XBM Hot Selling gypsum impact

US $56000