| Model: | DSE 85 90 95 |

|---|---|

| Brand: | DINGRUN |

| Origin: | Made In China |

| Category: | Industrial Supplies / Food, Beverage & Cereal Machine |

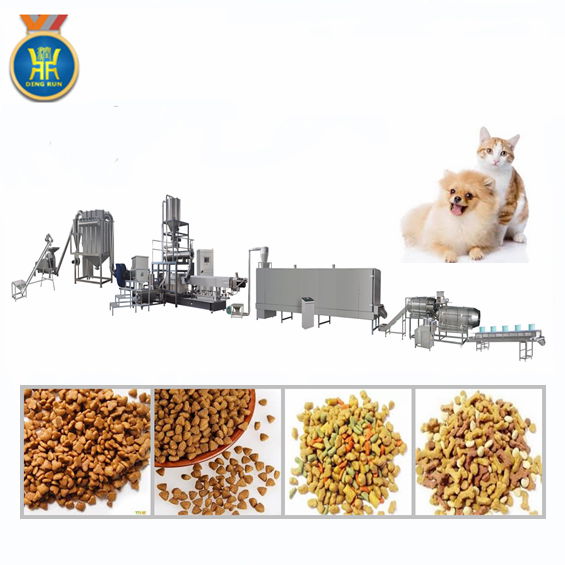

| Label: | pet food machine , dog feed extruder , cat Food equipment |

| Price: |

US $26000

/ pc

|

| Min. Order: | 1 pc |

Product Description

fish food extruder machine fish food line

Fish feed machine floating fish feed extruder machine

1. fish feed machine Description:

Fish feed machine is suitable to make dry and wet type fish food pellet (catfish, aquarium, Tilapia, Freshwater fish and tropical fish etc.)

1). All fish food equipments are made of stainless steel.

2). The fish food whole line fully continuous and automatic.

3). Dingrun provide basic fish food formula according to your require.

4). The final fish food shapes and sizes can be various by changing the mould.

5). Supply different size mould free of charge.

6). Packing machine could be supplied to work with the Fish feed machine floating fish feed extruder machine (depending on your require).

2. Raw materials for fish feed machine:

Most fish feed pellet inculding animal protein and plant protein, Plant protein adopts corn flour,rice flour,wheat flour,soybean flour,peanut cake powder…..Animal protein adopts fish meal, shrimp meal,crab meal, sleeve-fish meal and so on….you can add other ingredient according to the local fish live require.

Final products for Fish feed machine floating fish feed extruder machine:

fish feed pellet, fish food, pet food, dog food, cat food, animal food etc.

Fish feed machine parameters:

|

Model |

Installed Power |

Power Consumption |

Output |

Size |

|

DSE - 65 |

74 kw |

52 kw |

140-160 kg/hr |

17x1.3x2.2(m) |

|

DSE - 70 |

105 kw |

75 kw |

240-260 kg/hr |

20x1.5x2.2(m) |

|

DSE - 85 |

205kw |

150 kw |

500-600kg/hr |

30x1.5x2.6(m) |

|

DSE - 90 |

132kw |

75kw |

800-1200kg/hr |

35x2.5x3.8(m) |

|

DSE - 95 |

165kw |

90kw |

1500-2000kg/hr |

40x3.5x4.5(m) |

|

DSE - 130 |

280kw |

132kw |

3000-3500kg/hr |

45x4.5x6.0(m) |

Flow chart for fish feed machine floating fish feed pellet extruder machine whole line:

grinding→mixing→extruding→drying→flavoring→cooling→packaging

Description for the main machine of fish feed machine floating fish feed pellet extruder machine

Double Screw Extruder

For 2016 China popular floating fish feed pellet extruder machine

Model: DSE65, 70, 85, 90, 95

Capacity: from 100kg/h to 3000kg/h

1. Extruder is mainly composed of feeding, pre-conditioning, extrusion and cutting systems.

2. Main engine adopts inverter to adjust speed of screw according to changing of formula.

3. adopt building block system (BBS) to be adjustable for different technology.

4. Double-shaft pre-conditioner makes excellent result of mixing and conditioning, increasing capacity of extruder 10-15%.

5. Diameter of feed 1mm to 12mm can satisfy feed production for dog, cat, tortoise, bird, sea fish, shrimp and pet fish etc.

6.Self-cleaning, when stopping, it can be cleaned without disassembling.

Machines in our factory:

Material of the extruder machine for fish feed machine floating fish feed pellet extruder machine:

Protect panel: stainless steel 201, 304, 316, etc.

Parts contact food: stainless steel 304, 316, etc.

Material of the main parts for the extruder:

Brand of the main electrical parts inside the control panel for fish feed machine:

Dryer (electrical, steam, gas, diesel type)

For fish feed machine floating fish feed pellet extruder machine

Model: KX3-5, 5-5, 5-8, 5-10, 7-8, 7-10

Capacity: from 100kg/h to 3000kg/h

Belt width: 1300mm & above

Drying length: 10m~140m

Applied temperature(℃): 30~240

Drying time: 5~30 mins

Number of fans: 3~ 16 pcs

Structure: Multiple stainless steel belt

Feeding speed: 0.05-0.5 m/s

Steam consumption (t/h): 0.4~4.0

Application scope: Food industry,Feedstuff,Agricultural Products, Application Grain,Pet Food,Fish Feed,Puffed Snacks,Soybean Chunk,Pasta,Artificial rice,Vegetarian Meat,Etc

Flavoring system

For fish feed machine floating fish feed pellet extruder machine

including hoister, flavors feed and rolling drum

1. Fish-oil or other nutritious additives are sprayed on the surface of the pellets to improve palatability and conversion rate of feed.

2. Adopting drum pattern and oil atomization spraying system together with continuous and automatic operation.

3. Widely used for spraying fat, vitamin, substrate and medication onto the surface of extrusion feed.

Formation of fish feed machine production line:

1. Mixer: there are many kinds of model numbers to choose base on the production capacity.

2. Conveyor: to convey mixed raw materials to the extruder machine

3.Extruder machine: to choose DSE model extruders base on the production capacity requirement from 100kg per hour

to 3ton per hour. The raw material include corn powder, cereal powder, soybean powder, shrimp powder, fish meal and so on. Shape of the pellet depends on the moulds.

4. Hoister: to convey the fish food to the dryer, the height of the hoister depends on the dryer.

5. Multilayer dryer: electrical, gas, diesel, steam type, controlled by control box, temperature range 0-240ºC.Inside is

stainless steel double layer mesh net. Drying time is adjustable according to speed. We have dryers of 3 layer 5 meter,

5 layer 5 meter, 5 layer 7 meter, 5 layer 8 meter, 7 layer 8 meter, 5 layer 10 meter, and 7 layer 10 meter long.

6. Flavoring line: to spray oil and phagostimulant, the equipment are: single roller, double roller, round roller, eight-angle roller. Varies depends on the different production line setting, to spray oil to the surface of the product and make it

evenly.

7. Cooling conveyor: To cool the product temperature in order to pack it directly.

8. Sifter: To remove the wasted material and shapeless pellet, and ensure quality, meanwhile to ensure the reuse of material

9. Packaging machine: Manual and automatic packing machine. weight per bag according to your requirement.

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

Medium-sales service

*Every step of the production informed to client

*Machines produced according to client's confirmation

*Inspection and Delivery

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.

Packing & Delivery

Our Company

Certifications

FAQ

1. Q: Are you a trading company or a manufacturer?

A: We are the manufacturer, which has almost 10 years of experience in this industry.

2. Q: How can I get to your company?

A: That's great you can visit our factory, welcome! You can get a flight to Jinan Airport. Our factories are just about 30 minutes drive away from Jinan Airport.We are so glad to arrange our car pick you up!

3. Q: How long is your guarantee?

A: One year(Calculated from the equipment arrives the customer's side.).

After this period we will definitely support you when needed.

You will be welcome to contact us with any problem may happened.

4. Q: Will you send engineers to install the plant?

A: yes, our engineer will go to your place to install the fish feed machine and for training.

Or you can get local contractors to do the commissioning and we send one supervising engineer.

Ms. Amy

WhatsApp/cell: +86 15020006735

Wechat: 15020006735

or send me email directly:

amy at dingrunjixie.com

| Price Terms: | FOB QINGDAO |

|---|---|

| Payment Terms: | TT / LC / DP / DA |

| Packing: | plywood case |

| Lead Time: | 30 days |

| Standards Certificate: | SGS CE |

| Product condition: | new |

| Automacic: | full automatic |

| Raw materials: | grains powder, fish meal |

| Capacity: | 1 ton/h to 5 ton/h |

| Dimension: | various |

| Installed power: | 150kw |

Member Information

| JINAN DINGRUN EXTRUSION MACHINERY CO.,LTD | |

|---|---|

| Country/Region: | Shan Dong - China |

| Business Nature: | Manufacturer |

| Phone: | 15020006735 |

| Contact: | Ms. Amy (Sales Manager) |

| Last Online: | 11 Aug, 2018 |

Related Products of this Company

-

Fish feed machine Fish feed processing

US $3000

-

Puff corn food making machine

US $10000

-

Floating Fish feed extruder machine

US $10000

-

fried bugles snack food machine

US $10000

-

Kurkure corn snacks food processing line

US $10000

-

Bugles food processing machine /Frying

US $10000

-

260kg/h corn snacks food extruder

US $24000

-

Corn snacks food machine snack food

US $10000

-

Breakfast cereal corn flakes machine

US $10000

-

textured soy protein extruder

US $20000